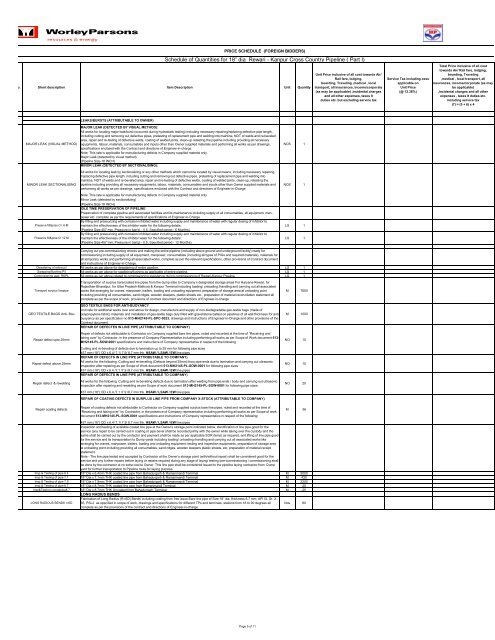

PRICE SCHEDULE (FOREIGN BIDDERS)Schedule of Quantities for 18” dia Rewari - Kanpur Cross Country Pipeline ( Part I)o. Short description Item Description Unit QuantityUnit Price inclusive of all cost towards Air/Rail fare, lodging,boarding, Traveling ,medical , localtransport, all insurances, in<strong>com</strong>e/corporate(as may be applicable) ,incidental chargesand all other expenses, taxes Itduties etc. but excluding service taxService Tax including cessapplicable onUnit Price(@ 12.36%)Total Price inclusive of all costtowards Air/ Rail fare, lodging,boarding, Traveling,medical , local transport, allinsurances, in<strong>com</strong>e/corporate (as maybe applicable),incidental charges and all otherexpenses , taxes It duties etc.including service tax(7) = (5 + 6) x 4LEAKS/BURSTS (ATTRIBUTABLE TO OWNER)MAJOR LEAK (VISUAL METHOD)MAJOR LEAK (DETECTED BY VISUAL METHOD):All works for locating major leak/burst (occurred during hydrostatic testing) including necessary repairing/replacing defective pipe length,including cutting and removing out defective pipes, pretesting of replacement pipe and welding into mainline, NDT of welds and re-beveledarea, repair and re-testing of defective welds, coating of welded joints, clean-up retesting the pipeline including providing all necessaryequipments, labour, materials, consumables and inputs other than Owner supplied materials and performing all works as per drawings,specifications enclosed with the Contract and directions of Engineer-in-charge.Note: This rate is applicable for manufacturing defects in Company supplied material only.Major Leak (detected by visual method)(Pipeline Size-18 INCH)MINOR LEAK (DETECTED BY SECTIONALISING):NOS 1MINOR LEAK SECTIONALISINGPreserve fill&prss.CI 6 MPreserve fill&prss.CI 12 MAll works for locating leak by sectionalizing or any other methods which cannot be located by visual means, including necessary repairing/replacing defective pipe length, including cutting and removing out defective pipes, pretesting of replacement pipe and welding intomainline, NDT of welds and re-bevelled area, repair and re-testing of defective welds, coating of welded joints, clean-up, retesting thepipeline including providing all necessary equipments, labour, materials, consumables and inputs other than Owner supplied materials andperforming all works as per drawings, specifications enclosed with the Contract and directions of Engineer-in-ChargeNote: This rate is applicable for manufacturing defects in Company supplied material onlyMinor Leak (detected by sectionalizing)(Pipeline Size-18 INCH)IDLE TIME PRESERVATION OF PIPELINEPreservation of <strong>com</strong>plete pipeline and associated facilities and its maintenance including supply of all consumables, all equipment, manpoweretc. <strong>com</strong>plete as per the requirements of specifications of Engineer-in-ChargeBy filling and pressurizing with corrosion inhibited water including supply and maintenance of water with regular dosing of inhibitor tomaintain the effectiveness of the inhibitor water for the following details:(Pipeline Size-457 mm, Pressure in bar(g) - 0.5, Specified period - 6 Months)By filling and pressurizing with corrosion inhibited water including supply and maintenance of water with regular dosing of inhibitor tomaintain the effectiveness of the inhibitor water for the following details:(Pipeline Size-457 mm, Pressure in bar(g) - 0.5, Specified period - 12 Months)NOSLSLS111Carrying out pre-<strong>com</strong>missioning checks and making the entire pipeline (including above ground and underground facility) ready for<strong>com</strong>missioning including supply of all equipment, manpower, consumables (including all types of PIGs and required materials), materials forall temporary works and performing all associated works, <strong>com</strong>plete as per the relevant specifications, other provisions of Contract documentand instructions of Engineer-in-Charge.Dewatering of entire p/l All works as per above for dewatering of entire pipeline. LS 1Swapping/flushing P/l All works as per above for swabbing/flushing as applicable of entire pipeline. LS 1Commisioning asst. RKPL All works as per above related to <strong>com</strong>missioning assistance during <strong>com</strong>missioning of Rewari-Kanpur Pipeline LS 1Transport surplus linepipeTransportation of surplus bare/coated line pipes from the dump sites to Company’s designated storage areas For Haryana-Rewari, forRajasthan-Bharatpur, for Uttar Pradesh-Mathura & Kanpur Terminal including loading/ unloading /handling and carrying out all associatedworks like arranging for cranes, manpower, trailers, loading and unloading equipment; preparation of storage area at unloading pointincluding providing all consumables, sand ridges, wooden sleepers, plastic sheets etc., preparation of material reconciliation statement all<strong>com</strong>plete as per the scope of work, provisions of contract document and directions of Engineer-in-chargeM 7650GEO TEXTILE BAGS Anti- BouRepair defect upto 25mmRepair defect above 25mmRepair defect & reweldingRepair coating defectsGEO TEXTILE BAGS FOR ANTI-BUOYANCYUnit rate for additional works over and above for design, manufacture and supply of non-biodegradable geo-textile bags (made ofpolypropylene fabric) materials and installation of geo-textile bags duly filled with gravel/stone ballast on pipelines of all wall thickness for antibuoyancyas per specification no 513-MH2145-PL-SPC-0023, drawings and instructions of Engineer-in-Charge and other provisions of theContract document.REPAIR OF DEFECTES IN LINE PIPE (ATTRIBUTABLE TO COMPANY)Repair of defects not attributable to Contractor on Company supplied bare line pipes, noted and recorded at the time of “Receiving andtaking over” by Contractor, in the presence of Company Representative including performing all works as per Scope of Work document 513-MH2145-PL-SOW-0001 specifications and instructions of Company representative in respect of the following :Cutting and re-beveling of defects due to lamination up to 25 mm for following pipe sizes457 mm (18”) OD x 6.4/ 7.1/ 7.9/ 8.7 mm thk. HSAW / LSAW / EW line pipesREPAIR OF DEFECTS IN LINE PIPE (ATTRIBUTABLE TO COMPANY)All works for the following :Cutting and re-bevelling (Defects beyond 25mm) from pipe ends due to lamination and carrying out ultrasonicinspection after repairing as per Scope of Work document 513-MH2145-PL-SOW-0001 for following pipe sizes:457 mm (18”) OD x 6.4 /7.1 /7.9 /8.7 mm thk. HSAW / LSAW / EW line pipesREPAIR OF DEFECTS IN LINE PIPE (ATTRIBUTABLE TO COMPANY)All works for the following :Cutting and re-bevelling defects due to lamination after welding from pipe ends / body and carrying out ultrasonicinspection after repairing and rewelding as per Scope of work document 513-MH2145-PL-SOW-0001 for following pipe sizes:457 mm (18”) OD x 6.4 /7.1 /7.9 /8.7 mm thk. HSAW / LSAW / EW line pipesREPAIR OF COATING DEFECTS IN SURPLUS LINE PIPE FROM COMPANY X-STOCK (ATTRIBUTABLE TO COMPANY)Repair of coating defects not attributable to Contractor on Company supplied surplus bare line pipes, noted and recorded at the time of“Receiving and taking over” by Contractor, in the presence of Company representative including performing all works as per Scope of workdocument 513-MH2145-PL-SOW-0001 specifications and instructions of Company representative in respect of the following:457 mm (18”) OD x 6.4/ 7.1/ 7.9/ 8.7 mm thk. HSAW / LSAW / EW line pipesInspection and testing of available coated line pipe at the Owner’s storage point indicated below, identification of line pipe good for theservice (any repair to be carried out in coating or pipe bevel shall be recorded jointly with the owner while taking over the custody and thesame shall be carried out by the contactor and payment shall be made as per applicable SOR items) as required, and lifting of line pipe goodfor the service and its transportation to Dump yards including loading/ unloading /handling and carrying out all associated works likearranging for cranes, manpower, trailers, loading and unloading equipment; testing and inspection equipments, preparation of storage areaat unloading point including providing all consumables, sand ridges, wooden sleepers plastic sheets, etc; preparation of material receiptstatement.Note - The line pipe tested and accepted by Contractor at the Owner’s storage point (with/without repair) shall be considered good for theservice and any further repairs before laying or repairs required during any stage of laying/ testing /pre-<strong>com</strong>missioning / <strong>com</strong>missioning shallbe done by the contractor at no extra cost to Owner. This line pipe shall be considered issued to the pipeline laying contractor from Dumpyard for further transportation to Pipeline route for laying purpose.MNONONOM100010102036Insp & Testing of pipe 6.4 18" Dia x 6.4mm THK coated line pipe from Bahadurgarh & Ramanmandi Terminal M 5000Insp & Testing of pipe 7.1 18" Dia x 7.1mm THK coated line pipe from Bahadurgarh & Ramanmandi Terminal M 430Insp & Testing of pipe 7.9 18" Dia x 7.9mm THK coated line pipe from Bahadurgarh & Ramanmandi Terminal M 2200Insp & Testing of pipe 8.7 18" Dia x 8.7mm THK coated line pipe from Ramanmandi Terminal M 25Insp&Testing uncoatpipe8.7 18" Dia x 8.7mm THK Uncoated from Bahadurgarh Terminal M 25LONG RADIUS BENDSLONG RADIOUS BENDS r=6DFabrication of Long Radius (R=6D) Bends including coating from free issue Bare line pipe of Size 18” dia, thickness 8.7 mm, API 5L Gr. X-65, PSL2 as specified in scope of work, drawings and specifications for different TPs and terminals, stations from 18 to 90 degrees all<strong>com</strong>plete as per the provisions of the contract and directions of Engineer-in-charge.Nos 80Page 5 of 11

PRICE SCHEDULE (FOREIGN BIDDERS)Schedule of Quantities for 18” dia Rewari - Kanpur Cross Country Pipeline ( Part I)o. Short description Item Description Unit QuantityELECTRONIC GEOMETRIC PIGGING OF PIPELINESCarrying out all works related to Magnetic Cleaning & Electronic Geometric Pigging (EGP) (inlcuding necessary runs of Magnetic Pig, EGP)of pipeline including defect verification at a max. of 2 locations for each identified segment of pipeline including preparation of site reports,data analysis, preparation & submissison of final report (6 sets), inlcuding supply of material, euipment , manpower etc.as required.This itemis inclusive of Mobilization/Demobilization of pigging tools, tackles, consumables, <strong>com</strong>pressors, pumps, accessories and personnel byCONTRACTOR at WORK SITE.as per specification and provisions of the bid document for 18” diameter Rewari-Kanpur Pipeline as perthe sections listed below:(defect verification shall preferably be made for defects not attributable to pipeline laying contractor)EGP : Rewari -mathura 18", 600# Pipeline between Rewari to Mathura (including Receiving & Launching from Bharatpur) M 160000EGP : Mathura- sayyadpur 18", 600# Pipeline between Mathura to Saiyyadpur Pran M 118300EGP: repair of defectP/l Mapper data gatheringRepair of defect identified in EGP not attributable to the pipeline laying contractor inlcuding all necessary works for defect repair like cutting,re-bevelling, welding (as required) including all material, manpower, consumables etc. all <strong>com</strong>plete as per the specifications & provisions ofbid document.PIPELINE DEFECT MAPPERData to be gathered throughout the strech of pipeline by using pipeline defect mapper, GPS co-ordinates along with depth of the pipleineshall be captured in 100 m intervals along the length of the pipeline including generation & submission of record all <strong>com</strong>plete as per thespecifications, scope of work and directions of Engineer-in-ChargeM 36Km 228Unit Price inclusive of all cost towards Air/Rail fare, lodging,boarding, Traveling ,medical , localtransport, all insurances, in<strong>com</strong>e/corporate(as may be applicable) ,incidental chargesand all other expenses, taxes Itduties etc. but excluding service taxService Tax including cessapplicable onUnit Price(@ 12.36%)Total Price inclusive of all costtowards Air/ Rail fare, lodging,boarding, Traveling,medical , local transport, allinsurances, in<strong>com</strong>e/corporate (as maybe applicable),incidental charges and all otherexpenses , taxes It duties etc.including service tax(7) = (5 + 6) x 4FABRICATION, WELDING, ERECTION, INSTALLATION & TESTING OF ABOVE GROUND PIPING : Receiving and Taking over of all (Owner andcontractor supplied) materials from Owner's designated place(s) of issue, transportation including loading, unloading, handling from Owner' designatedplace(s) of issue to Contractor's own stock yard(s)/ work site(s)/ work shop(s) including arranging all necessary intermediate storage area(s) thereof, asrequired; supply of all materials (except those specified subsequently in SOR), equipment, consumables as defined in Contractor's scope of supply andtheir transportation to the work site(s); performing all above ground/buried piping fabrication works including cutting, edge preparation (inclusive ofgrinding the edges of pipes, fittings, flanges etc. to match with the matching edges of uneven/different thickness wherever required),fit up, pre-heatingwherever required, welding, threading etc,; erection of pipes of all types and thickness over sleepers, overhead on racks and at all elevs, end seals,back fillings and restoration as original of the facility crossed and performing all works as per drawings, specifications, condFabr,weld inst AbvGrd pipeSuch as pressure/thermal safety valves(other than those covered separately), fittings of all sizes i.e, elbows, reducers, tees, 'o' lets, flanges, blindflanges, spectacle blinds, tappings for pressure gauges, thermo wells, hoses and hose couplings of all sizes, if applicable, sample connections, flamearrestors as applicable, vents and drains required for process and hydro-testing purposes etc. including supply & fixing of all types of gaskets (includinggaskets for RTJ flanges), bolts, studs and nuts of all sizes; fabrication of strainers of sizes up to 1.5" , carrying out non-destructive testing (excludingradiography covered subsequently in SOR) such as magnetic particle/ liquid penetration etc. as required; hook-up with existing piping/pipeline installedby others as per drawings wherever required; cleaning and flushing by water / <strong>com</strong>pressed air, carrying out hydrostatic test, pneumatic test, valvefunctional test and any other type of testing as specified, de-pressurizing, dewatering, drying by <strong>com</strong>prestion as original of the facility crossed andperforming all works as per drawings, specificatiand providing <strong>com</strong>missioning assistance to Commissioning Contractor / Agency for process piping and <strong>com</strong>missioning of non-process piping ifapplicable; clean - up and restoration of site, preparation of as built drawings, documents and project records; transportation of surplus free issuematerials to Owner's designated place(s); <strong>com</strong>pleting all works in all respects as per the AFC drawings, specifications , standards and other provisionsof Contract and instruction of Engineer-in-Charge. Note :- Installation of items such as valves (2" and above), flow meters, strainers of size 2" NB andabove, equipments will be paid separately as per rates covered in appropriate items. Radiography of weld joints would be measured and paid forseparately as per separate schedule item.Installation of above ground Carbon Steel Process Piping as per details given below: Size 2 INCH , Thk/Sch 80 , Material ASTM A106 Gr. B ,RADIOGRAPHYRadiography of weld joints of piping ( using gama or x-ray), including the cost of supply of all material, equipment and manpower required fordeveloping the films, review by ASNT qualified personnel, carrying out defect, repair, re-shoot etc. all <strong>com</strong>plete as per specifications and as directed bythe Engineer-in-charge. The radiography work shall be carried out <strong>com</strong>plying with all the statutory and safety requirements. Measurement will be donefor each weld joint of respective size of piping. In case of any repair, re-shoot, re takes, the same shall not be measured again for payment.M50RADIOGRAPHY DIN20NOS120PIPE SUPPORT suppy,erecPAINTING of pipeDN 20PIPE SUPPORTS: Supply, Fabrication and erection of pipe/equipment supports (for all sizes/thickness) including shoes, pipes, cradles, turnbuckles, t-posts for all types of guides, anchors, special supports for all types of pipes etc. If applicable, all necessary equipments, consumables, labouretc. for <strong>com</strong>pleting all works including supply of bolts, nuts, washers, U-clamp, wooden blocks etc. as required for supporting supply including the costof surface preparation by blast cleaning to SA 2.5, primer and painting all <strong>com</strong>plete as per specification, data sheets, drawings, terms and conditionsand as directed by the Engineer-in-charge.CS Structural SteelPAINTINGSupply and application of Paint including Surface preparation blast cleaning, supply of paints, solvents and primers, and application of primer and finishpaints suitable for project specific environment as defined in contract documents and on pipes as per standard specification for painting and protectivecoating as per attached specification no.MH2145-C000-PI-SPC-004, indentification, lettering / Numbering, colour coading etc. as specified includingrub down and touch up wherever required and providing of scaffolding for all heights, labour, materials, tools and tackles, consumable, supervision etc.to <strong>com</strong>plete the work in all respect as per specification, Drawings, standards and instruction of engineer-in -charge.Painting of all above ground piping including all valves fittings, flanges etc. including colour bands Size 2 INCH , Painting Environment NormalCorrosive ,KG 1500M2 60ALL GENERAL CIVIL WORKS AND BUILDING WORKS AS MENTIONED BELOW COMPLETE FOR SV STATION : SV-01, 02, 03, 04, 05, 06GENERAL CIVIL WORKS :Design, carrying out geotechnical survey and topographical survey, detail engineering, preparing construction and fabrication drawings, obtainingapproval of drawings and designs from engineer-in-charge, and construction of all general civil works viz. land development, site grading involvingcutting and filling (upto a depth of 1.2m) as per actual site conditions. <strong>com</strong>pound wall (upto a length of 180 mts), gates, approach road (with bitumentopping) from existing road (upto 50 sq. m surface area) , internal roads, drains, culverts, road crossings for electrical and instrumentation cables,pavements, footpath, drinking water system, plumbing work for toilets, construction of tube well including supply and installation of submersible pump,obtaining approval for tubewell from the statutory authorities, structural cage for all valves including preparing design and drawing as per actual sitedetails of valves, water harvesting system, and other miscellaneous works at SV Stations including supply of labour, materition as original of the facilitycrossed and performing all works as per drawings, specifications, conditions of crossing approval, instructions of Engineer-In-Charge and provisions ofContract document .Note: For HDD works, the measurement shallBUILDING WORKS :Design, detailed engineering, preparing construction and fabrication drawings, obtaining approval of drawings and designs from the engineer-in-charge,construction of structural and architectural works for civil buildings and other miscellaneous structures, transportation, erection, fabrication, painting,finishing etc., all <strong>com</strong>plete to make ready for <strong>com</strong>missioning including switchgear & control room building for all SV stations as indicated in theattached layout plans, including supply of all labour, material, equipment etc., <strong>com</strong>plete as per specification, preliminary and conceptual drawings,design basis, approved drawings, codes and standards, other terms and conditions and as per the direction of Engineer-in-charge.REFERENCE DOCUMENTS :1) SCOPE OF WORK : DOC.NO. : MH2145-C000-CI-SOW-00022) ARCHITECTURAL SPECIFICATION : DOC.NO. MH2145-C000-AR-SPC-0001 TO 00043) ARCHITECTURAL DESIGN BASIS : DOC.NO. MH2145-C000-AR-BOD-00014) CIVIL/STRUCTURAL SPECIFICATION : DOC.NO.MH2145-C000-CI-SPC-0001 TO 0012 & MH2145-C000-ST-SPC-0001 TO 00025) CIVIL/STRUCTURAL DESIGN BASIS : DOC.NO. MH2145-C000-CI-BOD-00016) SV SUILDING TYPE-1 (SV-01, 02, 03 04, 05, 06) STATION- ARCHITECTURAL DRAWINGS( GROUND FLOOR & ROOF PLAN, ELEVATIONS& SECTIONS, FINISHES SCHEDULE) : MH2145-C000-AR-DSK-0001 TO 00037) ARCHITECTURAL STANDARD DRAWINGS : MH2145-C000-AR-DST-0001 TO 00048) CIVIL/STRUCTURAL STANDARD DRAWINGS : MH2145-C000-CI-DST-0001 TO 0008 & MH2145-C000-ST-DST-0001, 0002 &00049) GENERAL CIVIL LAYOUT FOR SV STATION SV STATION (SV-01,02,03,04,05,06) : MH2145-C130-CI-DGA-0001All the above for SV station land acquired by HPCL, including obtaining approvals from concerned road authority for laying of approachroad to SV stations from the nearest road, preparation of layout plan of stations showing outside roads etc.obtaining the permission of localauthorities for construction of SV station building all <strong>com</strong>plete as per the scope of work, provisions of contract document and directions ofEngineer-in-Charge.SV1 STATION WORKS For SV-1 station @ approx. Ch: 34.095 , Village: Ramnagar Nichala LS 1SV2 STATION WORKS For SV-2 station @ apporx. Ch: 58.234, Village: Mubirukpur LS 1SV3 STATION WORKS For SV-3 station @approx. Ch: 92.699, Village: Qutubpur LS 1SV4 STATION WORKS For SV-4 station @approx. Ch: 117.435, Village: Supawasa LS 1SV5 STATION WORKS For SV-5 station @approx. Ch: 184.929, Village: Ghuncha LS 1SV6 STATION WORKS For SV-6 station @approx. Ch: 227.706, Village: Rajnagar LS 1All the above Including acquisition of Land in the name of HPCL for SV Stations along the pipeline route at chainage marked in thealignment sheets and as per the scope defined in Scope of Work document No. 513-MH2145-PL-SOW-0001, collection of revenuerecords, establishing correctness of ownership by search/revenue records, nil encumbrances, expediting subsequent formalities includingsigning of agreements or sale deed, if any, to facilitate possession of land by HPCL, Making payment to land owners, obtaining all requiredapprovals/no objection certificates from concerned authorities like village panchayats or municipalities etc. under whose jurisdiction eachplot of land falls, for constructing and setting up the SV Stations, obtaining approvals from concerned road authority for laying of approachroad to SV stations from the nearest road, registering the land in HPCL’s name including entry of HPCL’s name in original Jamabandi onthe acquired plot no. and obtaining copy of the same in support. Statutory fees as applicable like stamp duty etc.shall be paid by HPCL.Prepare layout plan of station showing outside roads etc. all <strong>com</strong>plete as per the scope of work, provisions of contract document anddirections of Engineer-in-Charge. Typically the area required for each SV station is approx. (50m X 40m). Payment shall be made basis persq.m area of the SV land.Page 6 of 11

- Page 1 and 2:

Hindustan Petroleum Corporation Ltd

- Page 3 and 4:

CHAPTER 1REQUEST FOR QUOTATION (RFQ

- Page 5 and 6:

Local ConditionsIt will be imperati

- Page 7:

The tender details including EMD, B

- Page 10 and 11:

his bid shall not be considered for

- Page 12 and 13:

5) This prime member shall be solel

- Page 14 and 15:

Note:1. All the information require

- Page 16 and 17:

EMD submitted by the bidder for sub

- Page 18 and 19:

however, bids in hard copies shall

- Page 20 and 21:

7.0 A firm which is not a PSU or an

- Page 22 and 23:

We are unable to bid for the reason

- Page 24 and 25:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 26 and 27:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 28 and 29:

QUOTATION AGAINST TENDERENQUIRY (En

- Page 30 and 31:

INDEXSR. NO.ARTICLE DESCRIPTION1.0

- Page 32 and 33:

modify the Bid Document. The amendm

- Page 34 and 35:

sealed and pasted with the enclosed

- Page 36 and 37:

l. Declaration with the bid qualifi

- Page 38 and 39:

Fax:91-22-67818080 in the presence

- Page 40 and 41:

for Part-II. In case such bidder is

- Page 42 and 43:

In case if the bidder quotes the ra

- Page 44 and 45:

xv)xvi)xvii)Non Submission of decla

- Page 46 and 47:

(c)When it is not possible to ascer

- Page 48 and 49:

14.7.2 To offset Central Sales Tax

- Page 50 and 51:

Where based on workability assessme

- Page 52 and 53:

tender terms not in deviation sheet

- Page 54 and 55:

INDEXSr. No. Article Description1.

- Page 56 and 57:

GENERAL TERMS & CONDITIONS OF CONTR

- Page 58 and 59:

2. 8 The "Drawings" shall include m

- Page 60 and 61:

3.6 The quantities indicated in the

- Page 62 and 63:

wherever required in the tender pap

- Page 64 and 65:

For working on Sundays/Holidays, th

- Page 66 and 67:

5.b COMMENCEMENT OF WORKThe contrac

- Page 68 and 69:

Contractor or the BG (if LD is full

- Page 70 and 71:

manufacture or fabrication or on th

- Page 72 and 73:

a. defects, if any, to be rectified

- Page 74 and 75:

payment of wages, salaries or other

- Page 76 and 77:

6.e.INSURANCE AND LABOURContractor

- Page 78 and 79:

iv. The contractor shall ensure tha

- Page 80 and 81:

7. PAYMENT OF CONTRACTOR'S BILLS7.

- Page 82 and 83:

shall be final and binding on the C

- Page 84 and 85:

7.e.4.Manufacturer's certificate sh

- Page 86 and 87:

accordance with the contract, the C

- Page 88 and 89:

12.0 TERMINATION OF CONTRACT12.1 Th

- Page 90 and 91:

Contractor to complete the job with

- Page 92 and 93:

shall be entitled at any time to in

- Page 94 and 95:

INDEX1. DEFINITION2. REFERENCE FOR

- Page 96 and 97:

and scope of work (technical), GPC

- Page 98 and 99:

In order to facilitate over-all exe

- Page 100 and 101:

Dimensions :For every order and eve

- Page 102 and 103:

26. CHANGESThe Owner has the option

- Page 104 and 105:

34. TECHNICAL INFORMATIONDrawings,

- Page 106 and 107:

Chapter: 4SPECIAL CONDITIONSOFCONTR

- Page 108 and 109:

44.0 DRAWINGS AND DOCUMENTS45.0 HOU

- Page 110 and 111:

viii) General Terms & Conditions of

- Page 112 and 113:

duties levied by statutory authorit

- Page 114 and 115:

stipulations including obtaining re

- Page 116 and 117:

4.1.3 Unless otherwise stated the t

- Page 118 and 119:

4.2.6 No Interest charges for delay

- Page 120 and 121:

9.0 PROVIDENT FUND, LABOUR, LABOUR

- Page 122 and 123:

not carried out work according to g

- Page 124 and 125:

16.a7 The Arbitrator may give a com

- Page 126 and 127:

19.0 Mobilization Advance19.1 Contr

- Page 128 and 129:

persons/persons or bodies/companies

- Page 130 and 131:

CONTRACTOR shall take all precautio

- Page 132 and 133:

Employer/Consultant shall not provi

- Page 134 and 135:

and return to the Contractor the st

- Page 136 and 137:

the work as per standards and all c

- Page 138 and 139:

42.0 COORDINATION WITH OTHER AGENCI

- Page 140 and 141:

pipelines, cables etc., during cons

- Page 142 and 143:

Engineer-in-charge during execution

- Page 144 and 145:

56.2 All the tests either on the fi

- Page 146 and 147:

The information to possible extent

- Page 148 and 149:

in part or in full.e) Functional Sc

- Page 150 and 151:

OWNER.66.4.4 Progress reports shall

- Page 152 and 153:

Order, or material of sub-standard

- Page 154 and 155:

75.11 Co-ordination with appropriat

- Page 156 and 157:

81.2 Contractor shall develop and s

- Page 158 and 159:

y them / Vendors shall be provided

- Page 160 and 161:

Contractor to note that it is their

- Page 162 and 163:

3.0 APPENDICES TO SCCMH2145-C000-PS

- Page 164 and 165:

SCOPE OF WORK & SUPPLY(APPENDIX-I t

- Page 166 and 167:

MATHURARKPL Project OfficeHPCL Depo

- Page 168 and 169:

12. Compensatory Afforestation as p

- Page 170 and 171:

TIME SCHEDULESr No Description Comp

- Page 172 and 173:

MEASUREMENT OF WORK(APPENDIX-III to

- Page 174 and 175:

The contractor shall submit the bil

- Page 176 and 177:

5.0 ELECTRICAL WORKS5.1 Cables5.1.1

- Page 178 and 179:

TERMS OF PAYMENT(APPENDIX-IV to SCC

- Page 180 and 181:

B) 5% on completion of all works in

- Page 182 and 183:

6.2.2 85% against completion of fou

- Page 184 and 185:

GENERAL NOTEBefore start of work, t

- Page 186 and 187:

3.1.4 The bidder shall submit, alon

- Page 188 and 189:

methodologies which he is going to

- Page 190 and 191:

Bidder’s Quality PlanPO/ Contact

- Page 192 and 193:

23Check for excessive temperature r

- Page 194 and 195:

LT MOTORSSlNo. ACTIVITY CONTRACTOR

- Page 196 and 197:

MLDB, LP AND PDBsSlNo. ACTIVITY CON

- Page 198 and 199:

PRELIMINARY CHECKS1 Check that cabl

- Page 200 and 201:

1.0 INTRODUCTION2.0 SCOPEThis docum

- Page 202 and 203:

4.4 TESTINGPrior to shop prefabrica

- Page 204 and 205:

6.0 ATTACHMENT (WAIVER/DEVIATION PE

- Page 206 and 207:

TO BE COMPLETED BY CUSTOMER ‘TECH

- Page 208 and 209:

APPENDIX -VI TO SCCHSE MANAGEMENT P

- Page 210 and 211:

INDEX1. CONDITIONS FOR ISSUE OF MAT

- Page 212 and 213:

NOTE :1)Landed Rate shall be arrive

- Page 214 and 215:

own cost to Owner's stores. In case

- Page 216 and 217:

MINIMUM NO. OF SKILLED MANPOWER (AT

- Page 218 and 219:

NOTE :-(1) The details of estimated

- Page 220 and 221:

MINIMUM EQUIPMENT DEPLOYMENT PART W

- Page 222 and 223:

22 Sand/Grit Blasting Cleaning M/c.

- Page 224 and 225:

45 GPS /GIS M/c for taking the co-o

- Page 226 and 227:

8 Excavator / Back Hoe (Ex 280/ 300

- Page 228 and 229:

31 Dead Weight Tester(Ravika 0-400k

- Page 230 and 231:

(2) Meeting the requirement of depl

- Page 232 and 233:

EXPERIENCE CRITERIA FOR KEY PERSONN

- Page 234 and 235:

1011LEAD WELDING /NDTENGINEERWAREHO

- Page 236 and 237:

1. The Labour rates are "all inclus

- Page 238 and 239:

EQUIPMENT HIRING/RECOVERY RATES(APP

- Page 240 and 241:

31. Pipe Trailers (FB / Semi Low Be

- Page 242 and 243:

INSTRUMENTS1. ELECTRONICS TRANSMITT

- Page 244 and 245:

16. SOLENOID VALVESA. AVCON CONTROL

- Page 246 and 247:

1. CENTRIFUGAL PUMPS VERTICAL - GEN

- Page 248 and 249:

G. UNIQUE INDUSTRIAL PACKINGSH. VIR

- Page 250 and 251:

K. TORMENE GAS TECHNOLOGY SPA, ITAL

- Page 252 and 253:

21. VALVE GLOBE FORGEDA. ASSOCIATED

- Page 254 and 255:

2. CABLES-CONTROL - PVCA. CCIB. FIN

- Page 256 and 257:

E. BHARTIA CUTLER HAMMER.F. CONTROL

- Page 258 and 259:

33. PERMANENT REFERENCE ELECTRODESA

- Page 260 and 261:

B. H & R JOHNSONC. BELL CERAMICSD.

- Page 262 and 263:

HINDUSTAN PETROLEUM CORPORATION LIM

- Page 264 and 265:

SR.No.A1234567BParticularsF13707 /C

- Page 266 and 267:

1 RJ/15/568 (P5322) - 24/12/2012234

- Page 268 and 269:

3NCR/GAS-O&M/DM(O&M)-152/2012/216 -

- Page 270 and 271:

2 34091/05/12-IA/728 - 3/5/2012G12H

- Page 272 and 273:

18192021222324252627282930313233342

- Page 274 and 275:

CHAPTER-5BRIEF SUMMARY OFAGREED TER

- Page 276 and 277:

(ix) Confirm acceptance of Liquidat

- Page 278 and 279:

1. Annexure-A Bid Security FormCHAP

- Page 280 and 281:

ANNEXURE-ABID SECURITY FORMBANK GUA

- Page 282 and 283:

COMPOSITE BANK GUARANTEE FOR SECURI

- Page 284 and 285:

writing.8. We, ....................

- Page 286 and 287:

ANNEXURE--DDECLARATION (NOT BANNED)

- Page 288 and 289:

ANNEXURE-FQUALIFICATION FORMAT - FO

- Page 290 and 291:

ANNEXURE-GIntegrity Pact[KK1]MH2145

- Page 292 and 293:

form part of this contract / supply

- Page 294 and 295:

INTEGRITY PACTBetweenHindustan Petr

- Page 296 and 297:

caused by him and has installed a s

- Page 298 and 299: Section 9 — Pact DurationThis Pac

- Page 300 and 301: MH2145-C000-PS-RFQ-0020Page 300 of

- Page 302 and 303: MH2145-C000-PS-RFQ-0020Page 302 of

- Page 304 and 305: Note:1. The message should be in Co

- Page 306 and 307: 3 . We ............................

- Page 308 and 309: ANNEXURE-JBANK GUARANTEE FOR MOBILI

- Page 310 and 311: 10. "The Bank" has power to issue t

- Page 312 and 313: servants and/or agents whatsoever t

- Page 314 and 315: UNDERTAKING (CORPORATE/ NON-CORPORA

- Page 316 and 317: ANNEXURE-NUNDERTAKING OF ADEQUATE C

- Page 318 and 319: 2 This Guarantee/Undertaking shall

- Page 320 and 321: Annexure-PNAME OF SUPPLY : ……

- Page 322 and 323: ANNEXURE - Q.1Business Rules for fi

- Page 324 and 325: v. After the completion of English

- Page 326 and 327: Annexure - Q.IIN.B.Terms & Conditio

- Page 328 and 329: Annexure- Q.IIIProcess Compliance F

- Page 330 and 331: Annexure Q.VCONTACT INFORMATION....

- Page 332 and 333: Annexure -SCERTIFICATE OF NON-INVOL

- Page 334 and 335: CHAPTER NO.8PRICE BID FORMATMH2145-

- Page 336 and 337: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 338 and 339: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 340 and 341: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 342 and 343: Item No. Item Description Unit Quan

- Page 344 and 345: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 346 and 347: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 350 and 351: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 352 and 353: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 354 and 355: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 356 and 357: m No. Short description Item Descri

- Page 358 and 359: m No. Short description Item Descri

- Page 360 and 361: m No. Short description Item Descri

- Page 362 and 363: m No. Short description Item Descri

- Page 364 and 365: Item No. Item Description Unit Quan

- Page 366 and 367: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 368 and 369: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 370 and 371: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 372 and 373: Item No.PRICE SCHEDULE (FOREIGN BID

- Page 374 and 375: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 376 and 377: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 378 and 379: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 380 and 381: UN PRICE SCHEDULE (FOREIGN BIDDERS)