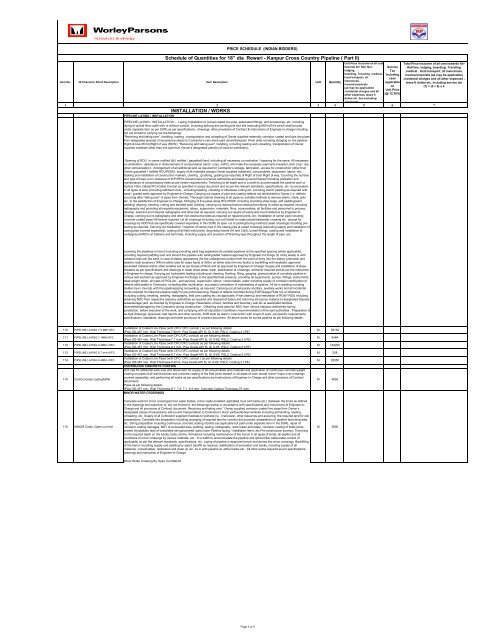

PRICE SCHEDULE (INDIAN BIDDERS)Schedule of Quantities for 18” dia Rewari - Kanpur Cross Country Pipeline ( Part II)798081828384858687Supply of BW Equal Tees as per details given below: Size 2 INCH , Thk/Sch 40 , Material ASTM A234 Gr WPB , Dmn. Std. ASME B16.9 , NOS 5SW equal Tee 2" sch 40Supply of BW Equal Tees as per details given below:Size 2 INCH , Thk/Sch 80 , Material ASTM A234 Gr WPB , Dmn. Std. ASME B16.9 , NOS 4SW equal Tee 2" sch 80Supply of BW Equal Tees as per details given below:Size 4 INCH , Thk/Sch 40 , Material ASTM A234 Gr WPB , Dmn. Std. ASME B16.9 , NOS 6SW equal Tee 4" sch 40Supply of BW Equal Tees as per details given below:Size 8 INCH , Thk/Sch 80 , Material ASTM A234 Gr WPB , Dmn. Std. ASME B16.9 , NOS 2SW equal Tee 8" sch 80Supply of BW Equal Tees as per details given below:Size 16 INCH , Thk/Sch 80 , Material WPHY X52, Welded AS PER MSS SP 75, NOS 5SW equal Tee 16" sch 80Supply of Seamless PBE Concentric Swage as per details given below:Size1- 2 INCH , Thk1/Sch1 80 , Size2- 3/4 INCH SCH 80 , MaterialNOS 3SeamlessPBE 2" 3/4"sch1 80 ASTM A105N, Dmn. Std. BS 3799Supply of Seamless BW Cap as per details given below:Size 2 INCH , Thk/Sch 80 , Material ASTM A234 Gr. WPB , Dmn. Std. ASME B16.9 NOS 15Seamless BW Cap 2" sch80Supply of 1.5 D 90 BW Elbow as per details given below:Size 2 INCH , Thk/Sch 80 , Material ASTM A234 Gr. WPB Seamless , Dmn. Std.NOS 151.5 D 90 BW elbow 2" sch80 ASME B16.9 ,Supply of BW Equal Tees as per details given below:Size 2 INCH , Thk/Sch 80 , Material ASTM A234 Gr WPB Seamless , Dmn. Std. ASMENOS 25BW equal Tee 2" sch 80 B16.9 ,CASED PIPESupply of Casing Pipe conforming to API 5Lor IS3589 and as per details given below:88 Casing pipe 24" 7.9mmM 620(Size-24INCH, Material -API 5L or IS3589, 7.9mm Thk.Supply of Conduit Pipe conforming to IS1239 and as per details given below:89 Conduit pipe 6"M 2620(Size-6INCH, Material -IS1239, Heavy Wall.Supply of Pipe conforming to PE pipe and as per details given below:90 HDPE pipe 2"M 5240(Size-2INCH, Material-HDPE,Heavy Pipe Thickness)91 Pipeline Defect Mapper Supply of 'PIPELINE DEFECT MAPPER as per the specification, scope of work and provisions of Contract Document. Nos 19293Fig 8 blind 2" 600#Fif 8 blind 4" 600#SUPPLY OF SPECTACLE BLINDSSupply of Fig. 8 Sp. Blind as per details given below:Size 2 INCH , Rating 600 , Material ASTM A105N , Face/Finish RF/125AARH , Dim.Std. ASME B 16.48 ,Supply of Fig. 8 Sp. Blind as per details given below:Size 4 INCH , Rating 600 , Material ASTM A105N , Face/Finish RF/125AARH , Dim.Std. ASME B 16.48 ,NOS 4NOS 5SUPPLY OF SPACER & BLINDSSupply of Spacer & Blind as per details given below:Size 16 INCH , Rating 600 , Material A516 GR. 70 , Face/Finish RF , Dmn. Std. ASME94NOS 3Space & Blind 16" 600# B16.48 ,95 Hose pipe 4" SUPPLY OF HOSE 4” as per the dats sheet, scope of work, specifications & provisions of the tender document Nos. 4SIGHT FLOW INDICATOR96Sight flow indicator DN 100Supply of SIGHT FLOW INDICATOR of size DN 100 as per the data sheet, scope of work, specifications and provisions of contract document NOS 4INSTRUMENTATION ITEMSSupply of wall mounted heat detector-Type: Rate of rise Heat, 24V DC, 4-20mA O/p, Safe Area, IP 42 (minimum). As per Specification no.97nos. 18Heat detector 24V IP42 MH2145-C000-00-IC-SPC-0009.Supply of wall mounted smoke detector-Type: Optical Type Smoke, 24V DC, 4-20mA O/p, Safe Area, IP42 (minimum). As per Specification no.98nos. 36Opt Smoke Detector24V IP42 MH2145-C000-00-IC-SPC-0009.Supply of wall mounted smoke detector-Type: lonisation Type Smoke, 24V DC, 4-20mA O/p, Safe Area, IP42 (minimum). As per Specification99nos. 24Ion Smoke detector24V ip42 no. MH2145-C000-00-IC-SPC-0009.100 H gasdetector battery room Supply of Hydrogen Gas Detector for Battery Room. As per Specification no. MH2145-C000-00-IC-SPC-0009. nos. 6101 MCP dbl action glass unit Supply of Manual Alarm Call Point double action "break glass" unit. As per Specification no. MH2145-C000-00-IC-SPC-0009. nos. 24102 Visual alrm 24v IP66 Ex pr Supply of Visual Alarm 24VDC,IP66,Explosion proof ,ZONE-1,IS. As per Specification no. MH2145-C000-00-IC-SPC-0009. nos. 24103 Audio Alrm 4V IP66 Ex prof Supply of Audio Alarm 4VDC,IP66,Explosion proof ,ZONE-1. As per Specification no. MH2145-C000-00-IC-SPC-0009. nos. 30104 TRV Supply of Thermal Relief Valves as per the data sheet, specification, scope of work and provisions of the contract document Nos 8105 Pressue gauges Supply of Pressure Gauges as per the data sheet, specification, scope of work and provisions of the contract document Nos 16106Supply of Pressure indicating Transmitter as per the data sheet, specification, scope of work and provisions of the contract document Nos 15Pressure indicator107Supply of Temperature Element with Temperature Transmitter (Skin Temeperature Measurement Type) as per the data sheet, specification,Nos 13Temp. elements with Transm scope of work and provisions of the contract108Supply of Temperature Element with Temperature Transmitter as per the data sheet, specification, scope of work and provisions of theNos 2Temp. elements with Transm contract109 OTDR Supply of Optical Time Domain Reflectometer (OTDR) as per the Specifications, Scope of Work, and provisions of the contract document nos. 1Note:1. Quantity indicated abve are tentative. Bidder to ascertain the acual quantity required for different site. Payment shall be made on the actual quantity installed.Page 2 of 9

PRICE SCHEDULE (INDIAN BIDDERS)Schedule of Quantities for 18” dia Rewari - Kanpur Cross Country Pipeline ( Part II)Unit Price inclusive of all costTotal Price inclusive of all cost towards Air/towards Air/ Rail fare, Service Rail fare, lodging, boarding, Travelinglodging,Tax ,medical , local transport, all insurances,boarding, Traveling ,medical , including in<strong>com</strong>e/corporate (as may be applicable)local transport, allcess ,incidental charges and all other expenses ,insurances,Item No. 30 Character Short Description Item Description Unit Quantityapplicable taxes It duties etc. including service taxin<strong>com</strong>e/corporateon(7) = (5 + 6) x 4(as may be applicable)Unit Price,incidental charges and all(@ 12.36%)other expenses, taxes Itduties etc. but excludingservice tax1 2 3 4 5 6 7INSTALLATION / WORKSPIPELINE LAYING / INSTALLATIONPIPELINE LAYING / INSTALLATION :- Laying /installation of buried coated line pipe, associated fittings, and accessories, etc. includinglaying of optical fibre cable with or without conduit, including splicing and jointing pits and kits (excluding MOVs/SVs which shall be paidunder separate item as per SOR) as per specifications, drawings, other provisions of Contract & instructions of Engineer-in-charge includingbut not limited to carrying out the followings:“Receiving and taking-over”, handling, loading , transportation and unloading of Owner supplied externally corrosion coated and bare line pipesfrom designated place(s) of issue/dump site(s) to Contractor’s own stock-yard (s)/workshop(s)/ Work (site) including stringing on the pipelineRight-of-Use (ROU)/Right of way (ROW); “Receiving and taking over”, handling, including loading and unloading, transportation of Ownersupplied materials other than line pipe from Owner’s designated place(s) of issue to worksite(s);Opening of ROU in owner notified (6(i) notified / gazzetted) land, including all necessary co-ordination / liasoning for the same. All necessaryco-oridination / assistance in disbursement of <strong>com</strong>pensation (land / crop). (HPCL will make the necessary payments towards Land/ crop / anyother <strong>com</strong>pensation). Arrangement of all additional land as required for Contractor’s storage, fabrication, access for construction (other thanOwner gazzetted / notified ROU/ROW); supply of all materials (except Owner supplied materials), consumables, equipment, labour, etc;Staking and installation of construction markers, clearing , grubbing, grading (as required) of Right of Use/ Right of way, Counting the numberand type of trees cut in presence of WP/HPCL/Government concerned authorities and keeping record thereof including plantation andmaintenance of <strong>com</strong>pensatory trees as per tender requirements; Trenching to all depth and to a width to ac<strong>com</strong>modate the pipeline and/ orOptical Fiber Cable(OFC)/Cable Conduit as specified in scope document and as per the relevant standards, specifications, etc. by excavationin all types of soils (including soft/hard rock) , including blasting, chiseling or otherwise cutting etc, providing trench padding as required withsand / graded earth approved by Engineer-in-Charge; Carrying out repairs of pipe and coating defects not attributable to Owner (i.e. defectsoccurring after “taking over” of pipes from Owner); Thorough internal cleaning of all pipes by suitable methods to remove debris, shots, gritsetc. to the satisfaction of Engineer-in-Charge; Stringing of line pipes along ROU/ROW including providing straw bags, soft padding/sandpadding; aligning, bending, cutting and beveled area, welding, carrying out destructive/non-destructive testing of welds as required includingradiography and providing all requisite equipment, labour, supervision, materials, films, consumables, all facilities and personnel to process,develop, examine and interpret radiographs and other test as required; carrying out repairs of weld joints found defective by Engineer-In-Charge, carrying out re-radiography and other non-destructive tests as required on repaired joints, etc; Installation of carrier pipe includingconcrete coated pipes (Wherever required ) at all crossings including; but not limited to roads/canals/nala/water crossing etc. (except forcrossings by HDD that are specifically covered separately in this SOR) by open cut or jacking/boring method (cased crossings) including pretestingas required; Carrying out installation / insertion of carrier pipe in the casing pipe at cased crossings (excluding supply and installation ofcasing pipe covered separately); coating of all field weld joints, long radius bends (HI and Cold), buried fittings, coating and installation ofunderground MOVs at Stations and terminals, including supply and provision of Warning tape throughout the length of pipe, etc;Lowering the pipelines in trench including providing sand bag separators for parallel pipelines at the specified spacing (when applicable),providing required padding over and around the pipeline with sand/graded material approved by Engineer-In-Charge (in rocky areas) or withcohesion less soil like sand in case of station approaches (for the underground portion from the point of entry into the station premises) andseisimic fault locations (1KM on etiher side for major faults or 500m on either side of minor faults) or backfilling with available, approvedexcavated material and/or other suitable soil as per Scope of Work and as approved by Engineer-In-Charge; Supply and installation of slopebreakers as per specifications and drawings in steep slope areas, bank stabilization at crossings, wherever required and as per the instructionof Engineer-In-charge; Carrying out hydrostatic testing including air cleaning, flushing, filling, gauging, pressurization of <strong>com</strong>plete pipeline invarious test sections as approved by Engineer-In-Charge to the specified test pressure, providing all equipments, pumps, fittings, instruments,dead weight tester, all types of PIGs etc., and services, supervision, labour, consumables, water including supply of corrosion rectification ofdefects attributable to Contractor, re-testing after rectification, successful <strong>com</strong>pletion of hydrotesting of pipeline. All tie-in welding includingGolden tie-in, tie-in(s) with the pipeline/piping re-beveling, as required. Carrying out all temporary ancillary, auxiliary works and all incidentalworks required to make the pipeline ready for pre-<strong>com</strong>missioning; Repair of defects recorded during EGP/Gauge Plate run or otherwiseincluding cutting, beveling, welding, radiography, field joint coating etc; as applicable, Final clean-up and restoration of ROW/ ROU includingobtaining NOC from respective statutory authorities as required and disposal of debris and returning all surplus material to designated disposalareas/storage yard, as directed by Engineer-In-Charge; Restoration of land, facilities and boundary wall etc at associated facilitiesdismantled/damaged by the Contractor during construction ; Obtaining work permits/ NOC from various statutory authorities havingjurisdiction, before execution of the work, and <strong>com</strong>plying with all stipulation /conditions /re<strong>com</strong>mendation of the said authorities ; Preparation ofas-built drawings, pipe-book, test reports and other records. SOR shall be read in conjunction with scope of work, job specific requirements,specifications, standards, drawings and other provisions of contract document. All above works for buried pipeline as per following details:Installation of Coated Line Pipes (with OFC/ OFC conduit ) as per following details:110 PIPELINE LAYING 7.9 MM+OFCM 38130(Pipe OD-457 mm, Wall Thickness-7.9mm, Pipe Grade-API 5L Gr X-65, PSL2, Coating-3 LPE)Installation of Coated Line Pipes (with OFC/OFC conduit) as per following details :111 PIPELINE LAYING 7.1MM+OFCM 5494(Pipe OD-457 mm, Wall Thickness-7.1 mm, Pipe Grade-API 5L Gr X-65, PSL2, Coating-3 LPE)Installation of Coated Line Pipes (with OFC/OFC conduit) as per following details :112 PIPELINE LAYING 6.4MM +OFCM 140200(Pipe OD-457 mm, Wall Thickness-6.4 mm, Pipe Grade-API 5L Gr X-65, PSL2, Coating-3 LPE)Installation of Coated Line Pipes (with OFC/OFC conduit) as per following details :113 PIPELINE LAYING 8.7 mm+OFCM 258(Pipe OD-457 mm, Wall Thickness-8.7 mm, Pipe Grade-API 5L Gr X-65, PSL2, Coating-3 LPE)Installation of Coated Line Pipes (with OFC/ OFC conduit ) as per following details:114 PIPELINE LAYING 6.4MM +OFCM 32550(Pipe OD-457 mm, Wall Thickness-6.4mm, Pipe Grade-API 5L Gr X-60, PSL2, Coating-3 LPE)CONTINUOUS CONCRETE COATINGUnit rate for additional work over and above item for supply of all consumables and materials and application of continuous concrete weightcoating on pipes of all wall thickness and concrete coating of the filed joints thereof, in all areas of work except minor/ major river crossingscovered separately, and performing all works as per specifications and instructions of Engineer-In-Charge and other provisions of Contract115 ContConcrete coatingAllthkM 4650documents.Pipes as per following details:(Pipe OD-457 mm, Wall Thickness-8.7, 7.9, 7.1, 6.4 mm, Concrete Coating Thickness-75 mm)MINOR WATER CROSSINGS116MINOR Cross.-Open cut mtdComplete work for minor crossings(minor water bodies, minor roads-metalled, asphalted,mud cart tracks etc.) (between the limits as definedin the drawings and execution of, but not limited to, the followings works) in accordance with specifications and instructions of Engineer-In-Charge and all provisions of Contract document; Receiving and taking over “ Owner supplied corrosion coated line pipes from Owner’sdesignated places of issue/dump site (s) and transportation to Contractor’s stock yard/workshop/’worksite including all handling, loading ,unloading, etc. Supply of all Contractor supplied materials to worksite (s) , manpower, other resources and acquiring the required land for sitepreparations; Complete site preparation including arranging of required land for construction purpose, preparations of pipeline launching area,etc. String preparation including continuous concrete coating of joints (as applicable but paid under separate item in the SOR), repair ofcorrosion coating damages, NDT of re-beveled area, welding, testing, radiography, weld repair and retest, corrosion coating of fields joints,pretest (hyrdostatic test) of <strong>com</strong>pleted strings(covered /paid under Pipeline laying / installation item), etc.Pre-construction surveys; Trenchingto the required depth on the banks, beds, berms, formations including maintenance of the trench in all types of strata, all depths and allconditions of minor crossings by various methods, etc. to a width to ac<strong>com</strong>modate the pipeline and optical fiber cable/cable conduit (ifapplicable) as per the relevant standards, specifications, etc. Laying of pipeline in approved trench and across the minor crossings, Backfillingof the trench including supply and padding by select backfill as required, stabilization of excavation and banks, including supply of allmaterials, consumables, restoration and clean up etc. tie in with pipeline at either banks etc.; All other works required as per specifications,drawings and instruction of Engineer-In-ChargeM 3800Minor Water Crossing By Open Cut MethodPage 3 of 9

- Page 1 and 2:

Hindustan Petroleum Corporation Ltd

- Page 3 and 4:

CHAPTER 1REQUEST FOR QUOTATION (RFQ

- Page 5 and 6:

Local ConditionsIt will be imperati

- Page 7:

The tender details including EMD, B

- Page 10 and 11:

his bid shall not be considered for

- Page 12 and 13:

5) This prime member shall be solel

- Page 14 and 15:

Note:1. All the information require

- Page 16 and 17:

EMD submitted by the bidder for sub

- Page 18 and 19:

however, bids in hard copies shall

- Page 20 and 21:

7.0 A firm which is not a PSU or an

- Page 22 and 23:

We are unable to bid for the reason

- Page 24 and 25:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 26 and 27:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 28 and 29:

QUOTATION AGAINST TENDERENQUIRY (En

- Page 30 and 31:

INDEXSR. NO.ARTICLE DESCRIPTION1.0

- Page 32 and 33:

modify the Bid Document. The amendm

- Page 34 and 35:

sealed and pasted with the enclosed

- Page 36 and 37:

l. Declaration with the bid qualifi

- Page 38 and 39:

Fax:91-22-67818080 in the presence

- Page 40 and 41:

for Part-II. In case such bidder is

- Page 42 and 43:

In case if the bidder quotes the ra

- Page 44 and 45:

xv)xvi)xvii)Non Submission of decla

- Page 46 and 47:

(c)When it is not possible to ascer

- Page 48 and 49:

14.7.2 To offset Central Sales Tax

- Page 50 and 51:

Where based on workability assessme

- Page 52 and 53:

tender terms not in deviation sheet

- Page 54 and 55:

INDEXSr. No. Article Description1.

- Page 56 and 57:

GENERAL TERMS & CONDITIONS OF CONTR

- Page 58 and 59:

2. 8 The "Drawings" shall include m

- Page 60 and 61:

3.6 The quantities indicated in the

- Page 62 and 63:

wherever required in the tender pap

- Page 64 and 65:

For working on Sundays/Holidays, th

- Page 66 and 67:

5.b COMMENCEMENT OF WORKThe contrac

- Page 68 and 69:

Contractor or the BG (if LD is full

- Page 70 and 71:

manufacture or fabrication or on th

- Page 72 and 73:

a. defects, if any, to be rectified

- Page 74 and 75:

payment of wages, salaries or other

- Page 76 and 77:

6.e.INSURANCE AND LABOURContractor

- Page 78 and 79:

iv. The contractor shall ensure tha

- Page 80 and 81:

7. PAYMENT OF CONTRACTOR'S BILLS7.

- Page 82 and 83:

shall be final and binding on the C

- Page 84 and 85:

7.e.4.Manufacturer's certificate sh

- Page 86 and 87:

accordance with the contract, the C

- Page 88 and 89:

12.0 TERMINATION OF CONTRACT12.1 Th

- Page 90 and 91:

Contractor to complete the job with

- Page 92 and 93:

shall be entitled at any time to in

- Page 94 and 95:

INDEX1. DEFINITION2. REFERENCE FOR

- Page 96 and 97:

and scope of work (technical), GPC

- Page 98 and 99:

In order to facilitate over-all exe

- Page 100 and 101:

Dimensions :For every order and eve

- Page 102 and 103:

26. CHANGESThe Owner has the option

- Page 104 and 105:

34. TECHNICAL INFORMATIONDrawings,

- Page 106 and 107:

Chapter: 4SPECIAL CONDITIONSOFCONTR

- Page 108 and 109:

44.0 DRAWINGS AND DOCUMENTS45.0 HOU

- Page 110 and 111:

viii) General Terms & Conditions of

- Page 112 and 113:

duties levied by statutory authorit

- Page 114 and 115:

stipulations including obtaining re

- Page 116 and 117:

4.1.3 Unless otherwise stated the t

- Page 118 and 119:

4.2.6 No Interest charges for delay

- Page 120 and 121:

9.0 PROVIDENT FUND, LABOUR, LABOUR

- Page 122 and 123:

not carried out work according to g

- Page 124 and 125:

16.a7 The Arbitrator may give a com

- Page 126 and 127:

19.0 Mobilization Advance19.1 Contr

- Page 128 and 129:

persons/persons or bodies/companies

- Page 130 and 131:

CONTRACTOR shall take all precautio

- Page 132 and 133:

Employer/Consultant shall not provi

- Page 134 and 135:

and return to the Contractor the st

- Page 136 and 137:

the work as per standards and all c

- Page 138 and 139:

42.0 COORDINATION WITH OTHER AGENCI

- Page 140 and 141:

pipelines, cables etc., during cons

- Page 142 and 143:

Engineer-in-charge during execution

- Page 144 and 145:

56.2 All the tests either on the fi

- Page 146 and 147:

The information to possible extent

- Page 148 and 149:

in part or in full.e) Functional Sc

- Page 150 and 151:

OWNER.66.4.4 Progress reports shall

- Page 152 and 153:

Order, or material of sub-standard

- Page 154 and 155:

75.11 Co-ordination with appropriat

- Page 156 and 157:

81.2 Contractor shall develop and s

- Page 158 and 159:

y them / Vendors shall be provided

- Page 160 and 161:

Contractor to note that it is their

- Page 162 and 163:

3.0 APPENDICES TO SCCMH2145-C000-PS

- Page 164 and 165:

SCOPE OF WORK & SUPPLY(APPENDIX-I t

- Page 166 and 167:

MATHURARKPL Project OfficeHPCL Depo

- Page 168 and 169:

12. Compensatory Afforestation as p

- Page 170 and 171:

TIME SCHEDULESr No Description Comp

- Page 172 and 173:

MEASUREMENT OF WORK(APPENDIX-III to

- Page 174 and 175:

The contractor shall submit the bil

- Page 176 and 177:

5.0 ELECTRICAL WORKS5.1 Cables5.1.1

- Page 178 and 179:

TERMS OF PAYMENT(APPENDIX-IV to SCC

- Page 180 and 181:

B) 5% on completion of all works in

- Page 182 and 183:

6.2.2 85% against completion of fou

- Page 184 and 185:

GENERAL NOTEBefore start of work, t

- Page 186 and 187:

3.1.4 The bidder shall submit, alon

- Page 188 and 189:

methodologies which he is going to

- Page 190 and 191:

Bidder’s Quality PlanPO/ Contact

- Page 192 and 193:

23Check for excessive temperature r

- Page 194 and 195:

LT MOTORSSlNo. ACTIVITY CONTRACTOR

- Page 196 and 197:

MLDB, LP AND PDBsSlNo. ACTIVITY CON

- Page 198 and 199:

PRELIMINARY CHECKS1 Check that cabl

- Page 200 and 201:

1.0 INTRODUCTION2.0 SCOPEThis docum

- Page 202 and 203:

4.4 TESTINGPrior to shop prefabrica

- Page 204 and 205:

6.0 ATTACHMENT (WAIVER/DEVIATION PE

- Page 206 and 207:

TO BE COMPLETED BY CUSTOMER ‘TECH

- Page 208 and 209:

APPENDIX -VI TO SCCHSE MANAGEMENT P

- Page 210 and 211:

INDEX1. CONDITIONS FOR ISSUE OF MAT

- Page 212 and 213:

NOTE :1)Landed Rate shall be arrive

- Page 214 and 215:

own cost to Owner's stores. In case

- Page 216 and 217:

MINIMUM NO. OF SKILLED MANPOWER (AT

- Page 218 and 219:

NOTE :-(1) The details of estimated

- Page 220 and 221:

MINIMUM EQUIPMENT DEPLOYMENT PART W

- Page 222 and 223:

22 Sand/Grit Blasting Cleaning M/c.

- Page 224 and 225:

45 GPS /GIS M/c for taking the co-o

- Page 226 and 227:

8 Excavator / Back Hoe (Ex 280/ 300

- Page 228 and 229:

31 Dead Weight Tester(Ravika 0-400k

- Page 230 and 231:

(2) Meeting the requirement of depl

- Page 232 and 233:

EXPERIENCE CRITERIA FOR KEY PERSONN

- Page 234 and 235:

1011LEAD WELDING /NDTENGINEERWAREHO

- Page 236 and 237:

1. The Labour rates are "all inclus

- Page 238 and 239:

EQUIPMENT HIRING/RECOVERY RATES(APP

- Page 240 and 241:

31. Pipe Trailers (FB / Semi Low Be

- Page 242 and 243:

INSTRUMENTS1. ELECTRONICS TRANSMITT

- Page 244 and 245:

16. SOLENOID VALVESA. AVCON CONTROL

- Page 246 and 247:

1. CENTRIFUGAL PUMPS VERTICAL - GEN

- Page 248 and 249:

G. UNIQUE INDUSTRIAL PACKINGSH. VIR

- Page 250 and 251:

K. TORMENE GAS TECHNOLOGY SPA, ITAL

- Page 252 and 253:

21. VALVE GLOBE FORGEDA. ASSOCIATED

- Page 254 and 255:

2. CABLES-CONTROL - PVCA. CCIB. FIN

- Page 256 and 257:

E. BHARTIA CUTLER HAMMER.F. CONTROL

- Page 258 and 259:

33. PERMANENT REFERENCE ELECTRODESA

- Page 260 and 261:

B. H & R JOHNSONC. BELL CERAMICSD.

- Page 262 and 263:

HINDUSTAN PETROLEUM CORPORATION LIM

- Page 264 and 265:

SR.No.A1234567BParticularsF13707 /C

- Page 266 and 267:

1 RJ/15/568 (P5322) - 24/12/2012234

- Page 268 and 269:

3NCR/GAS-O&M/DM(O&M)-152/2012/216 -

- Page 270 and 271:

2 34091/05/12-IA/728 - 3/5/2012G12H

- Page 272 and 273:

18192021222324252627282930313233342

- Page 274 and 275:

CHAPTER-5BRIEF SUMMARY OFAGREED TER

- Page 276 and 277:

(ix) Confirm acceptance of Liquidat

- Page 278 and 279:

1. Annexure-A Bid Security FormCHAP

- Page 280 and 281:

ANNEXURE-ABID SECURITY FORMBANK GUA

- Page 282 and 283:

COMPOSITE BANK GUARANTEE FOR SECURI

- Page 284 and 285:

writing.8. We, ....................

- Page 286 and 287: ANNEXURE--DDECLARATION (NOT BANNED)

- Page 288 and 289: ANNEXURE-FQUALIFICATION FORMAT - FO

- Page 290 and 291: ANNEXURE-GIntegrity Pact[KK1]MH2145

- Page 292 and 293: form part of this contract / supply

- Page 294 and 295: INTEGRITY PACTBetweenHindustan Petr

- Page 296 and 297: caused by him and has installed a s

- Page 298 and 299: Section 9 — Pact DurationThis Pac

- Page 300 and 301: MH2145-C000-PS-RFQ-0020Page 300 of

- Page 302 and 303: MH2145-C000-PS-RFQ-0020Page 302 of

- Page 304 and 305: Note:1. The message should be in Co

- Page 306 and 307: 3 . We ............................

- Page 308 and 309: ANNEXURE-JBANK GUARANTEE FOR MOBILI

- Page 310 and 311: 10. "The Bank" has power to issue t

- Page 312 and 313: servants and/or agents whatsoever t

- Page 314 and 315: UNDERTAKING (CORPORATE/ NON-CORPORA

- Page 316 and 317: ANNEXURE-NUNDERTAKING OF ADEQUATE C

- Page 318 and 319: 2 This Guarantee/Undertaking shall

- Page 320 and 321: Annexure-PNAME OF SUPPLY : ……

- Page 322 and 323: ANNEXURE - Q.1Business Rules for fi

- Page 324 and 325: v. After the completion of English

- Page 326 and 327: Annexure - Q.IIN.B.Terms & Conditio

- Page 328 and 329: Annexure- Q.IIIProcess Compliance F

- Page 330 and 331: Annexure Q.VCONTACT INFORMATION....

- Page 332 and 333: Annexure -SCERTIFICATE OF NON-INVOL

- Page 334 and 335: CHAPTER NO.8PRICE BID FORMATMH2145-

- Page 338 and 339: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 340 and 341: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 342 and 343: Item No. Item Description Unit Quan

- Page 344 and 345: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 346 and 347: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 348 and 349: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 350 and 351: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 352 and 353: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 354 and 355: PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 356 and 357: m No. Short description Item Descri

- Page 358 and 359: m No. Short description Item Descri

- Page 360 and 361: m No. Short description Item Descri

- Page 362 and 363: m No. Short description Item Descri

- Page 364 and 365: Item No. Item Description Unit Quan

- Page 366 and 367: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 368 and 369: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 370 and 371: UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 372 and 373: Item No.PRICE SCHEDULE (FOREIGN BID

- Page 374 and 375: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 376 and 377: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 378 and 379: PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 380 and 381: UN PRICE SCHEDULE (FOREIGN BIDDERS)