Draft Detailed Project Report

Rohtak

Rohtak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

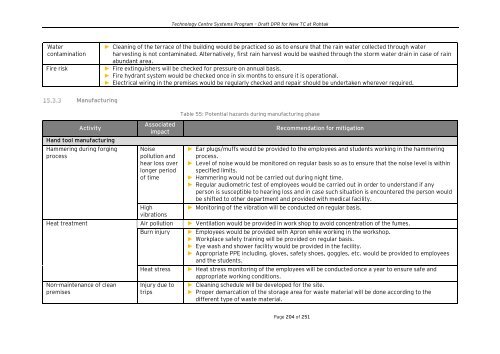

Technology Centre Systems Program – <strong>Draft</strong> DPR for New TC at Rohtak<br />

Water<br />

contamination<br />

Fire risk<br />

► Cleaning of the terrace of the building would be practiced so as to ensure that the rain water collected through water<br />

harvesting is not contaminated. Alternatively, first rain harvest would be washed through the storm water drain in case of rain<br />

abundant area.<br />

► Fire extinguishers will be checked for pressure on annual basis.<br />

► Fire hydrant system would be checked once in six months to ensure it is operational.<br />

► Electrical wiring in the premises would be regularly checked and repair should be undertaken wherever required.<br />

Manufacturing<br />

Activity<br />

Hand tool manufacturing<br />

Hammering during forging<br />

process<br />

Associated<br />

impact<br />

Noise<br />

pollution and<br />

hear loss over<br />

longer period<br />

of time<br />

High<br />

vibrations<br />

Table 55: Potential hazards during manufacturing phase<br />

Recommendation for mitigation<br />

► Ear plugs/muffs would be provided to the employees and students working in the hammering<br />

process.<br />

► Level of noise would be monitored on regular basis so as to ensure that the noise level is within<br />

specified limits.<br />

► Hammering would not be carried out during night time.<br />

► Regular audiometric test of employees would be carried out in order to understand if any<br />

person is susceptible to hearing loss and in case such situation is encountered the person would<br />

be shifted to other department and provided with medical facility.<br />

► Monitoring of the vibration will be conducted on regular basis.<br />

Heat treatment Air pollution ► Ventilation would be provided in work shop to avoid concentration of the fumes.<br />

Burn injury ► Employees would be provided with Apron while working in the workshop.<br />

► Workplace safety training will be provided on regular basis.<br />

► Eye wash and shower facility would be provided in the facility.<br />

► Appropriate PPE including, gloves, safety shoes, goggles, etc. would be provided to employees<br />

and the students.<br />

Non-maintenance of clean<br />

premises<br />

Heat stress<br />

Injury due to<br />

trips<br />

► Heat stress monitoring of the employees will be conducted once a year to ensure safe and<br />

appropriate working conditions.<br />

► Cleaning schedule will be developed for the site.<br />

► Proper demarcation of the storage area for waste material will be done according to the<br />

different type of waste material.<br />

Page 204 of 251