Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14.41 When pressing potentiometer onto<br />

spindle, apply finger pressure only to<br />

shaded area<br />

41 Refitting is the reverse of the removal<br />

procedure, noting the following:<br />

a) Carefully clean the mating surfaces of the<br />

throttle housing <strong>and</strong> potentiometer.<br />

b) Refit the potentiometer so that the flat on<br />

the spindle is aligned with the mating<br />

portion of the potentiometer.<br />

c) When pressing the potentiometer onto<br />

the spindle, apply finger pressure only to<br />

the shaded area shown (see illustration).<br />

d) Rotate the potentiometer anti-clockwise<br />

only to align the fixing holes.<br />

e) Tighten the potentiometer screws to their<br />

specified torque wrench setting.<br />

f) Operate the throttle cam 2 or 3 times<br />

<strong>and</strong> ensure that full travel exists<br />

between the throttle open <strong>and</strong> closed<br />

positions.<br />

Engine management<br />

(ignition/fuel injection) ECU<br />

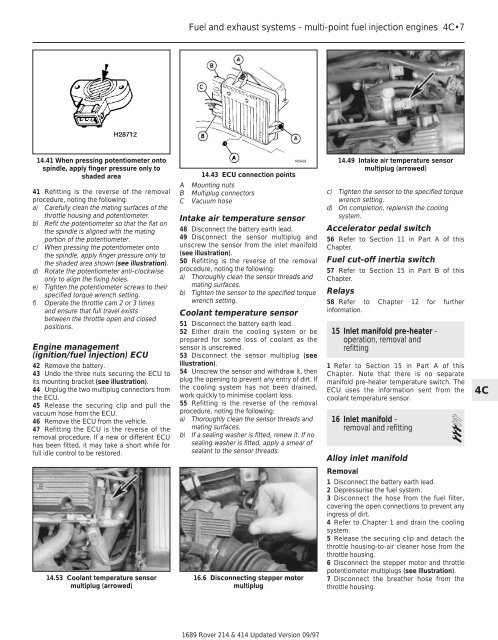

42 Remove the battery.<br />

43 Undo the three nuts securing the ECU to<br />

its mounting bracket (see illustration).<br />

44 Unplug the two multiplug connectors from<br />

the ECU.<br />

45 Release the securing clip <strong>and</strong> pull the<br />

vacuum hose from the ECU.<br />

46 Remove the ECU from the vehicle.<br />

47 Refitting the ECU is the reverse of the<br />

removal procedure. If a new or different ECU<br />

has been fitted, it may take a short while for<br />

full idle control to be restored.<br />

14.53 Coolant temperature sensor<br />

multiplug (arrowed)<br />

Fuel <strong>and</strong> exhaust systems - multi-point fuel injection engines 4C•7<br />

14.43 ECU connection points<br />

A Mounting nuts<br />

B Multiplug connectors<br />

C Vacuum hose<br />

Intake air temperature sensor<br />

48 Disconnect the battery earth lead.<br />

49 Disconnect the sensor multiplug <strong>and</strong><br />

unscrew the sensor from the inlet manifold<br />

(see illustration).<br />

50 Refitting is the reverse of the removal<br />

procedure, noting the following:<br />

a) Thoroughly clean the sensor threads <strong>and</strong><br />

mating surfaces.<br />

b) Tighten the sensor to the specified torque<br />

wrench setting.<br />

Coolant temperature sensor<br />

51 Disconnect the battery earth lead.<br />

52 Either drain the cooling system or be<br />

prepared for some loss of coolant as the<br />

sensor is unscrewed.<br />

53 Disconnect the sensor multiplug (see<br />

illustration).<br />

54 Unscrew the sensor <strong>and</strong> withdraw it, then<br />

plug the opening to prevent any entry of dirt. If<br />

the cooling system has not been drained,<br />

work quickly to minimise coolant loss.<br />

55 Refitting is the reverse of the removal<br />

procedure, noting the following:<br />

a) Thoroughly clean the sensor threads <strong>and</strong><br />

mating surfaces.<br />

b) If a sealing washer is fitted, renew it. If no<br />

sealing washer is fitted, apply a smear of<br />

sealant to the sensor threads.<br />

16.6 Disconnecting stepper motor<br />

multiplug<br />

1689 <strong>Rover</strong> <strong>214</strong> & <strong>414</strong> Updated Version 09/97<br />

14.49 Intake air temperature sensor<br />

multiplug (arrowed)<br />

c) Tighten the sensor to the specified torque<br />

wrench setting.<br />

d) On completion, replenish the cooling<br />

system.<br />

Accelerator pedal switch<br />

56 Refer to Section 11 in Part A of this<br />

Chapter.<br />

Fuel cut-off inertia switch<br />

57 Refer to Section 15 in Part B of this<br />

Chapter.<br />

Relays<br />

58 Refer<br />

information.<br />

to Chapter 12 for further<br />

15 Inlet manifold pre-heater -<br />

operation, removal <strong>and</strong><br />

refitting<br />

1 Refer to Section 15 in Part A of this<br />

Chapter. Note that there is no separate<br />

manifold pre-heater temperature switch. The<br />

ECU uses the information sent from the<br />

coolant temperature sensor.<br />

16 Inlet manifold -<br />

removal <strong>and</strong> refitting 3<br />

Alloy inlet manifold<br />

Removal<br />

1 Disconnect the battery earth lead.<br />

2 Depressurise the fuel system.<br />

3 Disconnect the hose from the fuel filter,<br />

covering the open connections to prevent any<br />

ingress of dirt.<br />

4 Refer to Chapter 1 <strong>and</strong> drain the cooling<br />

system.<br />

5 Release the securing clip <strong>and</strong> detach the<br />

throttle housing-to-air cleaner hose from the<br />

throttle housing.<br />

6 Disconnect the stepper motor <strong>and</strong> throttle<br />

potentiometer multiplugs (see illustration).<br />

7 Disconnect the breather hose from the<br />

throttle housing.<br />

4C