Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5C•6 Starting <strong>and</strong> charging systems<br />

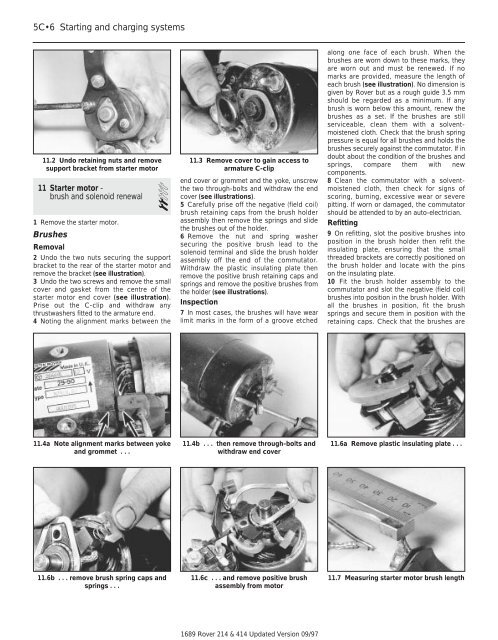

11.2 Undo retaining nuts <strong>and</strong> remove<br />

support bracket from starter motor<br />

11 Starter motor -<br />

brush <strong>and</strong> solenoid renewal 2<br />

1 Remove the starter motor.<br />

Brushes<br />

Removal<br />

2 Undo the two nuts securing the support<br />

bracket to the rear of the starter motor <strong>and</strong><br />

remove the bracket (see illustration).<br />

3 Undo the two screws <strong>and</strong> remove the small<br />

cover <strong>and</strong> gasket from the centre of the<br />

starter motor end cover (see illustration).<br />

Prise out the C-clip <strong>and</strong> withdraw any<br />

thrustwashers fitted to the armature end.<br />

4 Noting the alignment marks between the<br />

11.4a Note alignment marks between yoke<br />

<strong>and</strong> grommet . . .<br />

11.6b . . . remove brush spring caps <strong>and</strong><br />

springs . . .<br />

11.3 Remove cover to gain access to<br />

armature C-clip<br />

end cover or grommet <strong>and</strong> the yoke, unscrew<br />

the two through-bolts <strong>and</strong> withdraw the end<br />

cover (see illustrations).<br />

5 Carefully prise off the negative (field coil)<br />

brush retaining caps from the brush holder<br />

assembly then remove the springs <strong>and</strong> slide<br />

the brushes out of the holder.<br />

6 Remove the nut <strong>and</strong> spring washer<br />

securing the positive brush lead to the<br />

solenoid terminal <strong>and</strong> slide the brush holder<br />

assembly off the end of the commutator.<br />

Withdraw the plastic insulating plate then<br />

remove the positive brush retaining caps <strong>and</strong><br />

springs <strong>and</strong> remove the positive brushes from<br />

the holder (see illustrations).<br />

Inspection<br />

7 In most cases, the brushes will have wear<br />

limit marks in the form of a groove etched<br />

11.4b . . . then remove through-bolts <strong>and</strong><br />

withdraw end cover<br />

11.6c . . . <strong>and</strong> remove positive brush<br />

assembly from motor<br />

1689 <strong>Rover</strong> <strong>214</strong> & <strong>414</strong> Updated Version 09/97<br />

along one face of each brush. When the<br />

brushes are worn down to these marks, they<br />

are worn out <strong>and</strong> must be renewed. If no<br />

marks are provided, measure the length of<br />

each brush (see illustration). No dimension is<br />

given by <strong>Rover</strong> but as a rough guide 3.5 mm<br />

should be regarded as a minimum. If any<br />

brush is worn below this amount, renew the<br />

brushes as a set. If the brushes are still<br />

serviceable, clean them with a solventmoistened<br />

cloth. Check that the brush spring<br />

pressure is equal for all brushes <strong>and</strong> holds the<br />

brushes securely against the commutator. If in<br />

doubt about the condition of the brushes <strong>and</strong><br />

springs, compare them with new<br />

components.<br />

8 Clean the commutator with a solventmoistened<br />

cloth, then check for signs of<br />

scoring, burning, excessive wear or severe<br />

pitting. If worn or damaged, the commutator<br />

should be attended to by an auto-electrician.<br />

Refitting<br />

9 On refitting, slot the positive brushes into<br />

position in the brush holder then refit the<br />

insulating plate, ensuring that the small<br />

threaded brackets are correctly positioned on<br />

the brush holder <strong>and</strong> locate with the pins<br />

on the insulating plate.<br />

10 Fit the brush holder assembly to the<br />

commutator <strong>and</strong> slot the negative (field coil)<br />

brushes into position in the brush holder. With<br />

all the brushes in position, fit the brush<br />

springs <strong>and</strong> secure them in position with the<br />

retaining caps. Check that the brushes are<br />

11.6a Remove plastic insulating plate . . .<br />

11.7 Measuring starter motor brush length