Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2A•20 Engine in-car repair procedures<br />

15.4 Alternator adjuster link nut (A) wiring<br />

guide screws (B) oil pump bolts (C) <strong>and</strong><br />

special oil pump bolt (D)<br />

area so that it cannot be contaminated with<br />

oil.<br />

2 Drain the engine oil, then clean <strong>and</strong> refit the<br />

engine oil drain plug, tightening it to the<br />

specified torque wrench setting. If the engine<br />

is nearing its service interval when the oil <strong>and</strong><br />

filter are due for renewal, it is recommended<br />

that the filter is also removed <strong>and</strong> a new one<br />

fitted. After reassembly, the engine can then<br />

be replenished with fresh engine oil.<br />

3 Where necessary, unscrew the alternator<br />

adjuster link retaining nut <strong>and</strong> unbolt the<br />

engine wiring harness guide retaining screws,<br />

then move the link <strong>and</strong> guide clear of the oil<br />

pump.<br />

4 Unscrew the oil pump retaining bolts,<br />

noting the fitted position of the special bolt,<br />

<strong>and</strong> withdraw the oil pump (see illustration).<br />

Recover the pump gasket <strong>and</strong> discard it, then<br />

carefully lever the crankshaft right-h<strong>and</strong> oil<br />

seal out of the oil pump. The oil seal should be<br />

renewed whenever it is disturbed.<br />

Refitting<br />

5 Thoroughly clean the mating faces of the oil<br />

pump <strong>and</strong> cylinder block/crankcase. Use<br />

grease to stick a new gasket in place.<br />

6 Prime the pump before installation by<br />

injecting clean engine oil into it <strong>and</strong> turning it<br />

by h<strong>and</strong>.<br />

7 Offer up the pump, ensuring that its inner<br />

16.4 Unscrewing oil pressure relief valve<br />

threaded plug<br />

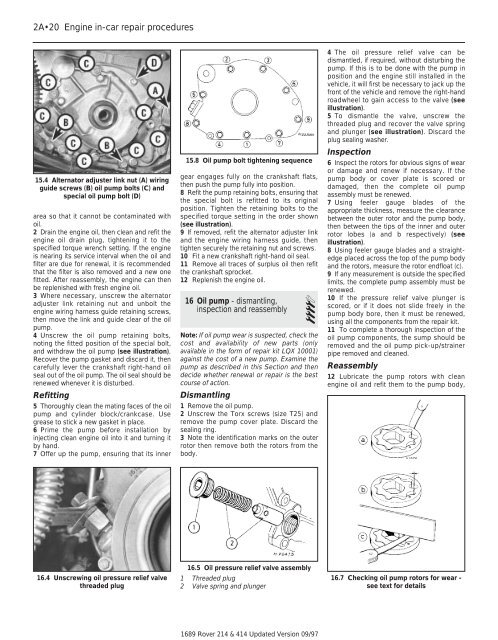

15.8 Oil pump bolt tightening sequence<br />

gear engages fully on the crankshaft flats,<br />

then push the pump fully into position.<br />

8 Refit the pump retaining bolts, ensuring that<br />

the special bolt is refitted to its original<br />

position. Tighten the retaining bolts to the<br />

specified torque setting in the order shown<br />

(see illustration).<br />

9 If removed, refit the alternator adjuster link<br />

<strong>and</strong> the engine wiring harness guide, then<br />

tighten securely the retaining nut <strong>and</strong> screws.<br />

10 Fit a new crankshaft right-h<strong>and</strong> oil seal.<br />

11 Remove all traces of surplus oil then refit<br />

the crankshaft sprocket.<br />

12 Replenish the engine oil.<br />

16 Oil pump - dismantling,<br />

inspection <strong>and</strong> reassembly 4<br />

Note: If oil pump wear is suspected, check the<br />

cost <strong>and</strong> availability of new parts (only<br />

available in the form of repair kit LQX 10001)<br />

against the cost of a new pump. Examine the<br />

pump as described in this Section <strong>and</strong> then<br />

decide whether renewal or repair is the best<br />

course of action.<br />

Dismantling<br />

1 Remove the oil pump.<br />

2 Unscrew the Torx screws (size T25) <strong>and</strong><br />

remove the pump cover plate. Discard the<br />

sealing ring.<br />

3 Note the identification marks on the outer<br />

rotor then remove both the rotors from the<br />

body.<br />

16.5 Oil pressure relief valve assembly<br />

1 Threaded plug<br />

2 Valve spring <strong>and</strong> plunger<br />

1689 <strong>Rover</strong> <strong>214</strong> & <strong>414</strong> Updated Version 09/97<br />

4 The oil pressure relief valve can be<br />

dismantled, if required, without disturbing the<br />

pump. If this is to be done with the pump in<br />

position <strong>and</strong> the engine still installed in the<br />

vehicle, it will first be necessary to jack up the<br />

front of the vehicle <strong>and</strong> remove the right-h<strong>and</strong><br />

roadwheel to gain access to the valve (see<br />

illustration).<br />

5 To dismantle the valve, unscrew the<br />

threaded plug <strong>and</strong> recover the valve spring<br />

<strong>and</strong> plunger (see illustration). Discard the<br />

plug sealing washer.<br />

Inspection<br />

6 Inspect the rotors for obvious signs of wear<br />

or damage <strong>and</strong> renew if necessary. If the<br />

pump body or cover plate is scored or<br />

damaged, then the complete oil pump<br />

assembly must be renewed.<br />

7 Using feeler gauge blades of the<br />

appropriate thickness, measure the clearance<br />

between the outer rotor <strong>and</strong> the pump body,<br />

then between the tips of the inner <strong>and</strong> outer<br />

rotor lobes (a <strong>and</strong> b respectively) (see<br />

illustration).<br />

8 Using feeler gauge blades <strong>and</strong> a straightedge<br />

placed across the top of the pump body<br />

<strong>and</strong> the rotors, measure the rotor endfloat (c).<br />

9 If any measurement is outside the specified<br />

limits, the complete pump assembly must be<br />

renewed.<br />

10 If the pressure relief valve plunger is<br />

scored, or if it does not slide freely in the<br />

pump body bore, then it must be renewed,<br />

using all the components from the repair kit.<br />

11 To complete a thorough inspection of the<br />

oil pump components, the sump should be<br />

removed <strong>and</strong> the oil pump pick-up/strainer<br />

pipe removed <strong>and</strong> cleaned.<br />

Reassembly<br />

12 Lubricate the pump rotors with clean<br />

engine oil <strong>and</strong> refit them to the pump body,<br />

16.7 Checking oil pump rotors for wear -<br />

see text for details