Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Rover 214 & 414 Service and Repair Manual - Rover club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10•20 Suspension <strong>and</strong> steering<br />

26.4a Power steering oil cooler upper<br />

mounting bolts (arrowed)<br />

4 Undo the three oil cooler mounting bracket<br />

retaining bolts, then manoeuvre the oil cooler<br />

assembly out from between the front bumper<br />

<strong>and</strong> body (see illustrations).<br />

Refitting<br />

5 Refitting is the reverse of the removal<br />

procedure. On completion, bleed the system.<br />

27 Power steering system -<br />

bleeding 2<br />

Warning: Avoid holding the<br />

steering at full lock for long<br />

periods of time. Failure to do so<br />

could lead to overheating, <strong>and</strong><br />

possible damage, of the power steering<br />

pump <strong>and</strong> steering gear.<br />

1 Remove the cap from the power steering<br />

fluid reservoir <strong>and</strong> fill the reservoir with the<br />

specified fluid.<br />

2 Disconnect the distributor wiring to prevent<br />

the engine from starting, then turn the engine<br />

over for approximately 5 seconds to prime the<br />

power steering pump.<br />

3 Reconnect the distributor wiring, then<br />

check the reservoir fluid level is between the<br />

MAX <strong>and</strong> MIN level markings on the side of<br />

the reservoir, topping up if necessary.<br />

4 Start the engine <strong>and</strong> allow it to idle for<br />

approximately 30 seconds with the front wheels<br />

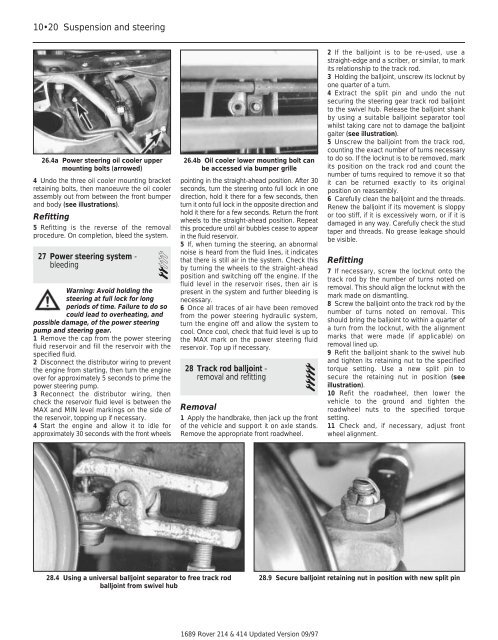

28.4 Using a universal balljoint separator to free track rod<br />

balljoint from swivel hub<br />

26.4b Oil cooler lower mounting bolt can<br />

be accessed via bumper grille<br />

pointing in the straight-ahead position. After 30<br />

seconds, turn the steering onto full lock in one<br />

direction, hold it there for a few seconds, then<br />

turn it onto full lock in the opposite direction <strong>and</strong><br />

hold it there for a few seconds. Return the front<br />

wheels to the straight-ahead position. Repeat<br />

this procedure until air bubbles cease to appear<br />

in the fluid reservoir.<br />

5 If, when turning the steering, an abnormal<br />

noise is heard from the fluid lines, it indicates<br />

that there is still air in the system. Check this<br />

by turning the wheels to the straight-ahead<br />

position <strong>and</strong> switching off the engine. If the<br />

fluid level in the reservoir rises, then air is<br />

present in the system <strong>and</strong> further bleeding is<br />

necessary.<br />

6 Once all traces of air have been removed<br />

from the power steering hydraulic system,<br />

turn the engine off <strong>and</strong> allow the system to<br />

cool. Once cool, check that fluid level is up to<br />

the MAX mark on the power steering fluid<br />

reservoir. Top up if necessary.<br />

28 Track rod balljoint -<br />

removal <strong>and</strong> refitting 5<br />

Removal<br />

1 Apply the h<strong>and</strong>brake, then jack up the front<br />

of the vehicle <strong>and</strong> support it on axle st<strong>and</strong>s.<br />

Remove the appropriate front roadwheel.<br />

1689 <strong>Rover</strong> <strong>214</strong> & <strong>414</strong> Updated Version 09/97<br />

2 If the balljoint is to be re-used, use a<br />

straight-edge <strong>and</strong> a scriber, or similar, to mark<br />

its relationship to the track rod.<br />

3 Holding the balljoint, unscrew its locknut by<br />

one quarter of a turn.<br />

4 Extract the split pin <strong>and</strong> undo the nut<br />

securing the steering gear track rod balljoint<br />

to the swivel hub. Release the balljoint shank<br />

by using a suitable balljoint separator tool<br />

whilst taking care not to damage the balljoint<br />

gaiter (see illustration).<br />

5 Unscrew the balljoint from the track rod,<br />

counting the exact number of turns necessary<br />

to do so. If the locknut is to be removed, mark<br />

its position on the track rod <strong>and</strong> count the<br />

number of turns required to remove it so that<br />

it can be returned exactly to its original<br />

position on reassembly.<br />

6 Carefully clean the balljoint <strong>and</strong> the threads.<br />

Renew the balljoint if its movement is sloppy<br />

or too stiff, if it is excessively worn, or if it is<br />

damaged in any way. Carefully check the stud<br />

taper <strong>and</strong> threads. No grease leakage should<br />

be visible.<br />

Refitting<br />

7 If necessary, screw the locknut onto the<br />

track rod by the number of turns noted on<br />

removal. This should align the locknut with the<br />

mark made on dismantling.<br />

8 Screw the balljoint onto the track rod by the<br />

number of turns noted on removal. This<br />

should bring the balljoint to within a quarter of<br />

a turn from the locknut, with the alignment<br />

marks that were made (if applicable) on<br />

removal lined up.<br />

9 Refit the balljoint shank to the swivel hub<br />

<strong>and</strong> tighten its retaining nut to the specified<br />

torque setting. Use a new split pin to<br />

secure the retaining nut in position (see<br />

illustration).<br />

10 Refit the roadwheel, then lower the<br />

vehicle to the ground <strong>and</strong> tighten the<br />

roadwheel nuts to the specified torque<br />

setting.<br />

11 Check <strong>and</strong>, if necessary, adjust front<br />

wheel alignment.<br />

28.9 Secure balljoint retaining nut in position with new split pin