Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

RESEARCH<br />

Grain refinement in DC casting of aluminium, Part II<br />

W. Schnei<strong>de</strong>r, Bonn; D. Granger, Murrysville<br />

Process and casting parameters<br />

affecting grain refinement<br />

The grain refinement of aluminium<br />

alloys with AlTiB and AlTiC master<br />

alloys in DC casting is influenced by<br />

a wi<strong>de</strong> variety of process parameters.<br />

The most important of these comprise:<br />

• Amount of master alloy ad<strong>de</strong>d,<br />

• Size and distribution of nucleant<br />

particles in the master alloy,<br />

• Efficiencies with which particles<br />

are dispersed in the melt,<br />

• Ti and B (or Ti and C) content of<br />

the master alloy,<br />

• Composition of the alloy to be<br />

refined, including Ti content,<br />

• Casting speed,<br />

• Casting temperature (or tempera-<br />

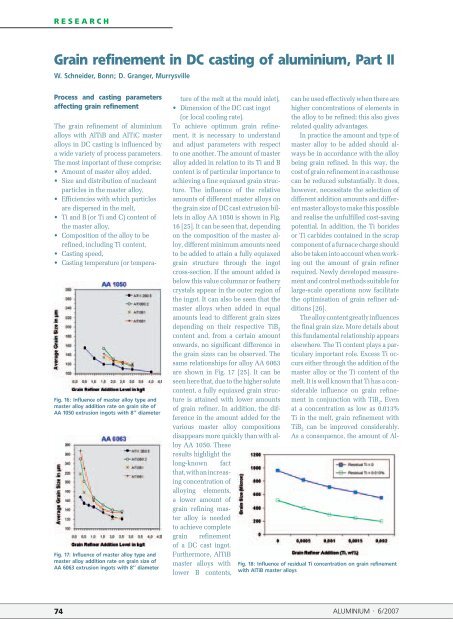

Fig. 16: Influence of master alloy type and<br />

master alloy addition rate on grain site of<br />

AA 1050 extrusion ingots with 8‘‘ diameter<br />

Fig. 17: Influence of master alloy type and<br />

master alloy addition rate on grain size of<br />

AA 6063 extrusion ingots with 8‘‘ diameter<br />

ture of the melt at the mould inlet),<br />

• Dimension of the DC cast ingot<br />

(or local cooling rate).<br />

To achieve optimum grain refinement,<br />

it is necessary to un<strong>de</strong>rstand<br />

and adjust parameters with respect<br />

to one another. The amount of master<br />

alloy ad<strong>de</strong>d in relation to its Ti and B<br />

content is of particular importance to<br />

achieving a fine equiaxed grain structure.<br />

The influence of the relative<br />

amounts of different master alloys on<br />

the grain size of DC cast extrusion billets<br />

in alloy AA 1050 is shown in Fig.<br />

16 [25]. It can be seen that, <strong>de</strong>pending<br />

on the composition of the master alloy,<br />

different minimum amounts need<br />

to be ad<strong>de</strong>d to attain a fully equiaxed<br />

grain structure through the ingot<br />

cross-section. If the amount ad<strong>de</strong>d is<br />

below this value columnar or feathery<br />

crystals appear in the outer region of<br />

the ingot. It can also be seen that the<br />

master alloys when ad<strong>de</strong>d in equal<br />

amounts lead to different grain sizes<br />

<strong>de</strong>pending on their respective TiB 2<br />

content and, from a certain amount<br />

onwards, no significant difference in<br />

the grain sizes can be observed. The<br />

same relationships for alloy AA 6063<br />

are shown in Fig. 17 [25]. It can be<br />

seen here that, due to the higher solute<br />

content, a fully equiaxed grain structure<br />

is attained with lower amounts<br />

of grain refiner. In addition, the difference<br />

in the amount ad<strong>de</strong>d for the<br />

various master alloy compositions<br />

disappears more quickly than with alloy<br />

AA 1050. These<br />

results highlight the<br />

long-known fact<br />

that, with an increasing<br />

concentration of<br />

alloying elements,<br />

a lower amount of<br />

grain refining master<br />

alloy is nee<strong>de</strong>d<br />

to achieve complete<br />

grain refinement<br />

of a DC cast ingot.<br />

Furthermore, AlTiB<br />

master alloys with<br />

lower B contents,<br />

can be used effectively when there are<br />

higher concentrations of elements in<br />

the alloy to be refined; this also gives<br />

related quality advantages.<br />

In practice the amount and type of<br />

master alloy to be ad<strong>de</strong>d should always<br />

be in accordance with the alloy<br />

being grain refined. In this way, the<br />

cost of grain refinement in a casthouse<br />

can be reduced substantially. It does,<br />

however, necessitate the selection of<br />

different addition amounts and different<br />

master alloys to make this possible<br />

and realise the unfulfilled cost-saving<br />

potential. In addition, the Ti bori<strong>de</strong>s<br />

or Ti carbi<strong>de</strong>s contained in the scrap<br />

component of a furnace charge should<br />

also be taken into account when working<br />

out the amount of grain refiner<br />

required. Newly <strong>de</strong>veloped measurement<br />

and control methods suitable for<br />

large-scale operations now facilitate<br />

the optimisation of grain refiner additions<br />

[26].<br />

The alloy content greatly influences<br />

the final grain size. More <strong>de</strong>tails about<br />

this fundamental relationship appears<br />

elsewhere. The Ti content plays a particulary<br />

important role. Excess Ti occurs<br />

either through the addition of the<br />

master alloy or the Ti content of the<br />

melt. It is well known that Ti has a consi<strong>de</strong>rable<br />

influence on grain refinement<br />

in conjunction with TiB 2 . Even<br />

at a concentration as low as 0.013%<br />

Ti in the melt, grain refinement with<br />

TiB 2 can be improved consi<strong>de</strong>rably.<br />

As a consequence, the amount of Al-<br />

Fig. 18: Influence of residual Ti concentration on grain refinement<br />

with AlTiB master alloys<br />

74 ALUMINIUM · 6/2007