Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

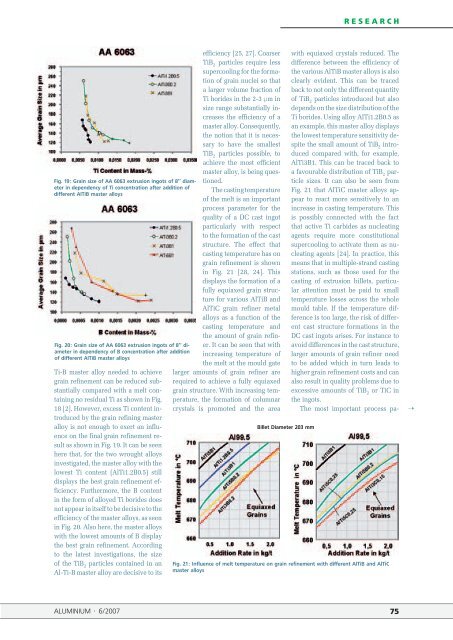

Fig. 19: Grain size of AA 6063 extrusion ingots of 8‘‘ diameter<br />

in <strong>de</strong>pen<strong>de</strong>ncy of Ti concentration after addition of<br />

different AlTiB master alloys<br />

Fig. 20: Grain size of AA 6063 extrusion ingots of 8‘‘ diameter<br />

in <strong>de</strong>pen<strong>de</strong>ncy of B concentration after addition<br />

of different AlTiB master alloys<br />

Ti-B master alloy nee<strong>de</strong>d to achieve<br />

grain refinement can be reduced substantially<br />

compared with a melt containing<br />

no residual Ti as shown in Fig.<br />

18 [2]. However, excess Ti content introduced<br />

by the grain refining master<br />

alloy is not enough to exert an influence<br />

on the final grain refinement result<br />

as shown in Fig. 19. It can be seen<br />

here that, for the two wrought alloys<br />

investigated, the master alloy with the<br />

lowest Ti content (AlTi1.2B0.5) still<br />

displays the best grain refinement efficiency.<br />

Furthermore, the B content<br />

in the form of alloyed Ti bori<strong>de</strong>s does<br />

not appear in itself to be <strong>de</strong>cisive to the<br />

efficiency of the master alloys, as seen<br />

in Fig. 20. Also here, the master alloys<br />

with the lowest amounts of B display<br />

the best grain refinement. According<br />

to the latest investigations, the size<br />

of the TiB 2 particles contained in an<br />

Al-Ti-B master alloy are <strong>de</strong>cisive to its<br />

ALUMINIUM · 6/2007<br />

efficiency [25, 27]. Coarser<br />

TiB 2 particles require less<br />

supercooling for the formation<br />

of grain nuclei so that<br />

a larger volume fraction of<br />

Ti bori<strong>de</strong>s in the 2-3 μm in<br />

size range substantially increases<br />

the efficiency of a<br />

master alloy. Consequently,<br />

the notion that it is necessary<br />

to have the smallest<br />

TiB 2 particles possible, to<br />

achieve the most efficient<br />

master alloy, is being questioned.<br />

The casting temperature<br />

of the melt is an important<br />

process parameter for the<br />

quality of a DC cast ingot<br />

particularly with respect<br />

to the formation of the cast<br />

structure. The effect that<br />

casting temperature has on<br />

grain refinement is shown<br />

in Fig. 21 [28, 24]. This<br />

displays the formation of a<br />

fully equiaxed grain structure<br />

for various AlTiB and<br />

AlTiC grain refiner metal<br />

alloys as a function of the<br />

casting temperature and<br />

the amount of grain refiner.<br />

It can be seen that with<br />

increasing temperature of<br />

the melt at the mould gate<br />

larger amounts of grain refiner are<br />

required to achieve a fully equiaxed<br />

grain structure. With increasing temperature,<br />

the formation of columnar<br />

crystals is promoted and the area<br />

Billet Diameter 203 mm<br />

RESEARCH<br />

with equiaxed crystals reduced. The<br />

difference between the efficiency of<br />

the various AlTiB master alloys is also<br />

clearly evi<strong>de</strong>nt. This can be traced<br />

back to not only the different quantity<br />

of TiB 2 particles introduced but also<br />

<strong>de</strong>pends on the size distribution of the<br />

Ti bori<strong>de</strong>s. Using alloy AlTi1.2B0.5 as<br />

an example, this master alloy displays<br />

the lowest temperature sensitivity <strong>de</strong>spite<br />

the small amount of TiB 2 introduced<br />

compared with, for example,<br />

AlTi3B1. This can be traced back to<br />

a favourable distribution of TiB 2 particle<br />

sizes. It can also be seen from<br />

Fig. 21 that AlTiC master alloys appear<br />

to react more sensitively to an<br />

increase in casting temperature. This<br />

is possibly connected with the fact<br />

that active Ti carbi<strong>de</strong>s as nucleating<br />

agents require more constitutional<br />

supercooling to activate them as nucleating<br />

agents [24]. In practice, this<br />

means that in multiple-strand casting<br />

stations, such as those used for the<br />

casting of extrusion billets, particular<br />

attention must be paid to small<br />

temperature losses across the whole<br />

mould table. If the temperature difference<br />

is too large, the risk of different<br />

cast structure formations in the<br />

DC cast ingots arises. For instance to<br />

avoid differences in the cast structure,<br />

larger amounts of grain refiner need<br />

to be ad<strong>de</strong>d which in turn leads to<br />

higher grain refinement costs and can<br />

also result in quality problems due to<br />

excessive amounts of TiB 2 or TiC in<br />

the ingots.<br />

The most important process pa-<br />

Fig. 21: Influence of melt temperature on grain refinement with different AlTiB and AlTiC<br />

master alloys<br />

75<br />

�