- Page 2 and 3: All reasonable steps have been take

- Page 4 and 5: Instrument Photographic Choice of I

- Page 6 and 7: iv Contents Chapter 5 - Maintenance

- Page 8 and 9: The specimen chamber of the Slereos

- Page 10 and 11: The User Interface Overview The use

- Page 12 and 13: 5. Panel Selection There is one oth

- Page 14 and 15: B If B is pressed. the arrow keys m

- Page 16 and 17: The top window, see Figure 1.3, pro

- Page 18 and 19: Individual items can be selected or

- Page 20 and 21: 1~1~ Chapter 1 Getting Started i '

- Page 22 and 23: all the operating conditions of the

- Page 24 and 25: 1-20 ~bapter 1 ~g S~ move the mouse

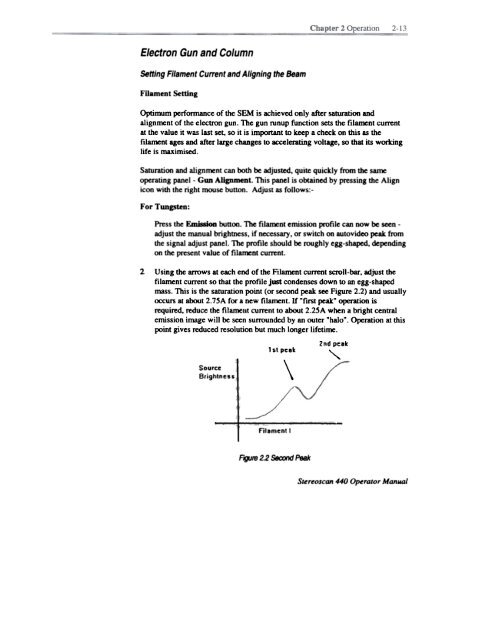

- Page 26 and 27: FIgUre 1.10 Image of First Peak Set

- Page 28 and 29: Chapter 2 This chapter contains the

- Page 30 and 31: Chapter 1. Operation 2--3 " -- Scan

- Page 32 and 33: Chapter 2. Operation 2.,.,5 ,- . ..

- Page 34 and 35: , , Chapter 1. ~ - 2-- 7 ""a-uu"" 1

- Page 36 and 37: 1. Admit air to the gun. Open the g

- Page 40 and 41: For LaB,:- 1 Press the Emission but

- Page 42 and 43: ~I.~ Chapter 2 Operation -'--"=-,'Z

- Page 44 and 45: 2-18 Chapter 1. Operation - - - - a

- Page 46 and 47: 2-20 Chapter 2. Operation. 1 2 t Se

- Page 48 and 49: 2-22 Chapter 1. Operation If the wo

- Page 50 and 51: 2-24 Chapter 2 Operation The Zone T

- Page 52 and 53: Quad Mode Quad mode is selected fro

- Page 54 and 55: 2-28 Chapter 2 Operation . - -, , "

- Page 56 and 57: On the histogram display there is a

- Page 58 and 59: Panels A panel is a special kind of

- Page 60 and 61: current text string). In addition t

- Page 62 and 63: Micron Markers Two types of micron

- Page 64 and 65: Graticule and Crosshairs Graticule

- Page 66 and 67: HRRU Camera This sets the type of c

- Page 68 and 69: 2..42 Cbapter 1. Operation ~ I It h

- Page 70 and 71: current when the image was saved. T

- Page 72 and 73: 2-46 Chapter 2 Operation The Clipbo

- Page 74 and 75: Having now become familiar with the

- Page 76 and 77: high a probe current, thus the acce

- Page 78 and 79: , Chapter 3 Advanced Operation 3-5

- Page 80 and 81: 3. The retractable backscattered el

- Page 82 and 83: I~.." - Chapter 3 Advanced Operatio

- Page 84 and 85: "".~-I Chapter 3 Advanced Operation

- Page 86 and 87: " Chapter 3 Advanced Operation 3-13

- Page 88 and 89:

Non-Volatile, Non-Conductors If it

- Page 90 and 91:

The solvent is then allowed to evap

- Page 92 and 93:

Chapter 3 Advanced ~OD 3-19 -c - -

- Page 94 and 95:

Other Menu Features The display of

- Page 96 and 97:

Points and Steps In addition to the

- Page 98 and 99:

Confirm This instruction check that

- Page 100 and 101:

._~ Chapter c" ~ 3 Advanced Operati

- Page 102 and 103:

Remove Removing a macro from a libr

- Page 104 and 105:

The position in the list can be con

- Page 106 and 107:

Install The install option copies t

- Page 108 and 109:

Chapter 3 AdvancedOperati on 3-35 3

- Page 110 and 111:

I I PARAMETER I En"ECT OPTIMUM COMM

- Page 112 and 113:

4.5. Good Housekeeping, i.e. keepin

- Page 114 and 115:

Chapter -. 4 System Management - +3

- Page 116 and 117:

4.1.5. Directory Contents I \nGA i

- Page 118 and 119:

4.3. The User Directory Concept A u

- Page 120 and 121:

I this be reql!i~. File Types, e.g.

- Page 122 and 123:

6-12 Chapter 6 Fault Diagnosis The

- Page 124 and 125:

5-2 Chapter 5 Maintenance 5.1.2. Ai

- Page 126 and 127:

STEEL AND ST ~S STEEL, COPPER AND m

- Page 128 and 129:

5-6 Chapter 5 Maintenance Cleaning

- Page 130 and 131:

Cleaning the Aperture Assembly Vent

- Page 132 and 133:

PC Related Faults PC related proble

- Page 134 and 135:

6-4 Chapter 6 Fault Diagnosis , .".

- Page 136 and 137:

6-6 Chapter 6 Fault Diagnosis The I

- Page 138 and 139:

6-8 Chapter 6 Fault Diagnosis . 4.

- Page 140 and 141:

6-10 Chapter 6 Fault Diagnosis! "I

- Page 142:

This file contains the configuratio

- Page 145 and 146:

Please report the problem. F All..E

- Page 147 and 148:

Stereoscan 440 Operator Manual NVRA

- Page 149 and 150:

6-20 Chapter 6 Fault Diagnosis 4 WW

- Page 151 and 152:

Code numbers greater than 40 indica

- Page 153 and 154:

WINDOWSTM APPUCA nON ERROR When a W

- Page 155 and 156:

Introduction As new Window~ applica

- Page 157 and 158:

Appendix ~ The Stereoscan 440 PC! A

- Page 159 and 160:

" c., Appeudb C Expansion via the P

- Page 161 and 162:

Appendix D Reporting software probl

- Page 163 and 164:

Service Manager - SEM Harry M azal

- Page 165 and 166:

B-2 Appendix E Options- . Operation

- Page 167 and 168:

Controls Angular Measurement The an

- Page 169 and 170:

Angular Measurement Each measuremen

- Page 171 and 172:

The position of the box can be adju

- Page 173 and 174:

I Set the magnification to the requ

- Page 175 and 176:

Positioning the Poin~ In Move mode

- Page 177 and 178:

&14 Appendix E Options I II Image D

- Page 179 and 180:

~ AMaxB This function freezes the i

- Page 181 and 182:

Histogram Equalisation The histogra

- Page 183 and 184:

Overview The input LUT is used to p

- Page 185 and 186:

E-22 Appendix E Options Sawtooth Th

- Page 187 and 188:

A group box at the top left of the

- Page 189 and 190:

" The communication port used by th

- Page 191 and 192:

Selection I The signal mixing panel

- Page 193 and 194:

E- 30 Appendix E Options Select one

- Page 195 and 196:

E-32 Appendix E Qptions . . High Us

- Page 197 and 198:

. The stage Move window comprises a

- Page 199 and 200:

Keyboard Control The cursor (arrow)

- Page 201 and 202:

E-38 Ap~ ~ Options In addition Macr

- Page 203 and 204:

Grainl Grain2 actionedl I To indica

- Page 205 and 206:

The function is provided as part of

- Page 207 and 208:

Operation Selection Operation of th

- Page 209 and 210:

Stage Scan Invalid This indicates i

- Page 211 and 212:

E-48 Appendix E Options ~-",,-;,,~_

- Page 213 and 214:

Freeze This function will freeze th

- Page 215 and 216:

1.21 Trackerbal/ Introduction This

- Page 217 and 218:

Controls Display the pop up control

- Page 219 and 220:

Operation Configuration XRay Interf

- Page 221 and 222:

E-58 Appendix E Options 11_- X Ray

- Page 223 and 224:

Intensity Dot Map Set Up In dot map

- Page 225 and 226:

The Linescan data is displayed in a

- Page 227 and 228:

E-64 AppeDdjx E ~oos ... ~~ full sc

- Page 229 and 230:

Annotation A set of annotation labe

- Page 231 and 232:

2. 2.1 Stage Motorisation The stage

- Page 233 and 234:

Camera Image Select between Live, S

- Page 235 and 236:

If the box marked Fast is selected,

- Page 237 and 238:

Remove the Camera assembly from the

- Page 239 and 240:

~--~- ~- , -~~::~ '#:r: .TungsIen F

- Page 241 and 242:

.,, , or_~ :---1 ' ' --~... 'FG'-~-

- Page 243 and 244:

Figures 9,10,11,12 Emission Images

- Page 245 and 246:

Assembly Assembly . of the STEM det

- Page 247 and 248:

4. Select SCM Image from the Specim

- Page 249 and 250:

~ ~ ~ ~ E I I I I I I Stereoscan 44

- Page 251 and 252:

DOS, 4-1 Dose rate, 3-12 Dual magni

- Page 253 and 254:

1-4 Index Rotary pump Oil. 5-2 Oil

- Page 255:

Appendices s+Shift ff ~ I ARRO~ ~ys