- Page 1 and 2:

NATIONAL MULTIPLE FAMILY SUBMETERIN

- Page 3 and 4:

CONTENTS LIST OF TABLES............

- Page 5 and 6:

Matched-Pair Analysis .............

- Page 7 and 8:

LIST OF TABLES Table ES.1.1 Breakdo

- Page 9:

Table 6.6 Elasticity values, analys

- Page 12 and 13:

Figure 4.30 RUBS water bill #6 ....

- Page 14 and 15:

investigated local water savings as

- Page 16 and 17:

We are grateful to the members of a

- Page 18 and 19:

quantitative aspects of separate bi

- Page 20 and 21:

3. Owner/postcard survey: To identi

- Page 22 and 23:

"averages" of impact property water

- Page 24 and 25:

in-rent properties, others used the

- Page 26 and 27:

of these models included the billin

- Page 28 and 29:

70 Average Annual Water Use Per Uni

- Page 30 and 31:

COSTS AND BENEFITS Beyond quantifyi

- Page 32 and 33:

service charge, then the resident w

- Page 34 and 35:

Billing Method Efficient Fixtures?

- Page 36 and 37:

70 Avg. Water Use per MF Unit (kgal

- Page 38 and 39:

REGULATORY FRAMEWORK REVIEW The fra

- Page 40 and 41:

Table ES.1.12 NSUAA Summary of Stat

- Page 42 and 43:

above, the researchers offer the fo

- Page 44 and 45:

service is preferable, and would he

- Page 46 and 47:

practices (BMPs) should be implemen

- Page 48 and 49:

infrastructure of the building and

- Page 50:

multi-family housing. The transfer

- Page 53 and 54:

CHAPTER 1 INTRODU CTION More and mo

- Page 55 and 56:

In 1998, 15.0%, or 15.4 million, of

- Page 57 and 58:

TERMINOLOGY AND DEFINITIONS OF BILL

- Page 59 and 60:

submetering. With utility-submeteri

- Page 61 and 62:

all the two bedroom units for $20 p

- Page 63 and 64:

HOW TO USE THIS REPORT This report

- Page 67 and 68:

CHAPTER 2 LITERAT URE REVIEW As the

- Page 69 and 70:

A review of the literature unearthe

- Page 71 and 72:

The price elasticity of water deman

- Page 73 and 74:

expected. Additionally, McClelland

- Page 75 and 76:

submetered and five control (in-ren

- Page 77 and 78:

Another study might want to target

- Page 81 and 82:

CHAPTER 3 RESEARC H METHODS, APPROA

- Page 83 and 84:

1. Selection of participating study

- Page 85 and 86:

STUDY SITE SELECTION The Study aime

- Page 87 and 88:

Figure 3.2 National Multiple Family

- Page 89 and 90:

Matched pair protocol/survey - conf

- Page 91 and 92:

information given the available bud

- Page 93 and 94:

survey. Service companies that prov

- Page 95 and 96:

in “business to business” calli

- Page 97 and 98:

MATCHED PAIR SAMPLE The purpose of

- Page 99 and 100:

The second part of the visit requir

- Page 101 and 102:

epresentative of a known population

- Page 103 and 104:

51 Table 3.7 Postcard survey statis

- Page 105 and 106:

Table 3.8 Comparison of annual wate

- Page 107 and 108:

postcard survey. Nevertheless, exam

- Page 109 and 110:

confidence interval ranged from 49.

- Page 111 and 112:

particular property (e.g., the mont

- Page 113 and 114:

State PUC officials - water commiss

- Page 115:

10. The PROPID number appearing on

- Page 118 and 119:

These costs represent the commodity

- Page 120 and 121:

The postcard survey provided inform

- Page 122 and 123:

Table 4.4 Average number of units f

- Page 124 and 125:

Two-thirds of the properties that r

- Page 126 and 127:

Percent of Surveyed Properties with

- Page 128 and 129:

$700 Average Rent Per Bedroom ($) $

- Page 130 and 131:

Percent of Surveyed Properties with

- Page 132 and 133:

Impact properties were also more li

- Page 134 and 135:

Table 4.8 Issues considered before

- Page 136 and 137:

Percent of Surveyed Impact Properti

- Page 138 and 139:

60% Percent of Surveyed Properties

- Page 140 and 141:

From the visits, it was found that

- Page 142 and 143:

100% Percent of Surveyed Residents

- Page 144 and 145:

Roughly similar proportions of resi

- Page 146 and 147:

inserts for toilets (21%) or low-fl

- Page 148 and 149:

proportion were unsure, 37% from su

- Page 150 and 151:

Table 4.18 Ownership and rental rat

- Page 152 and 153:

Figure 4.17 Submeter water bill #1

- Page 154 and 155:

Figure 4.18 Submeter water bill #2

- Page 156 and 157:

Figure 4.20 Submeter water bill #4

- Page 158 and 159:

wastewater rates are not shown so t

- Page 160 and 161:

Figure 4.23 Hot water hybrid water

- Page 162 and 163:

RUBS Sample Bills Seven sample RUBS

- Page 164 and 165:

wastewater rates are not shown so t

- Page 166 and 167:

Figure 4.28 RUBS water bill #4 from

- Page 168 and 169:

Figure 4.30 RUBS water bill #6 RUBS

- Page 170 and 171:

directly to and then paid by the th

- Page 172 and 173:

never subtracting for common area w

- Page 174 and 175:

Late Fees At the start of water bil

- Page 176 and 177:

124

- Page 178 and 179:

intuitively clear, and matches comm

- Page 180 and 181:

Indoor water use was normalized on

- Page 182 and 183:

Table 5.3 Summarized water use anal

- Page 184 and 185:

easonable assumption since there is

- Page 186 and 187:

Figure 5.1 shows the frequency dist

- Page 188 and 189:

40 Difference in Annual Water Use p

- Page 190 and 191:

after 1995. By including only those

- Page 192 and 193:

70 Average Annual Water Use Per Uni

- Page 194 and 195:

Table 5.11 Statistical tests compar

- Page 196 and 197:

Factors that Influence Water Use Th

- Page 198 and 199:

Table 5.12 Association of categoric

- Page 200 and 201:

Indoor Water Use per Unit in 2001 I

- Page 202 and 203:

Table 5.13 Continuous factors from

- Page 204 and 205:

Multivariate Models to Determine Im

- Page 206 and 207:

properties built before 1995 were c

- Page 208 and 209:

70 Average Annual Water Use Per Uni

- Page 210 and 211:

A = Beta coefficient for “Propert

- Page 212 and 213:

substantially reduces the sample si

- Page 214 and 215:

Table 5.17 Model #2 coefficients an

- Page 216 and 217:

0.00 indicating that whatever fit d

- Page 218 and 219:

commodity charge for water and wast

- Page 220 and 221:

properties having generally lower w

- Page 222 and 223:

110 Average Annual Water Use Per Un

- Page 224 and 225:

analysis, intended to control best

- Page 226 and 227:

Table 5.27 Paired samples test, all

- Page 228 and 229:

Table 5.30 Estimated water use befo

- Page 230 and 231:

Table 5.33 Comparison of water savi

- Page 232 and 233:

180

- Page 234 and 235:

sector only reduced usage by 18% (A

- Page 236 and 237:

Table 6.1 Avoided costs from submet

- Page 238 and 239:

submetered. Complete responses of c

- Page 240 and 241:

included in this cost/benefit analy

- Page 242 and 243:

Table 6.3 Cost and benefit for owne

- Page 244 and 245:

Perceived Concerns In the resident

- Page 246 and 247:

With a service fee, residents could

- Page 248 and 249:

Table 6.4 Economic return for a res

- Page 250 and 251: ANALYSIS OF PRICE ELASTICITIES Econ

- Page 252 and 253: concluded that if a single elastici

- Page 254 and 255: esults from this analysis point to

- Page 256 and 257: over which they have control than d

- Page 258 and 259: According to the basic consumer cho

- Page 260 and 261: The consumer choice problem can be

- Page 262 and 263: 210

- Page 264 and 265: water systems from compliance with

- Page 266 and 267: and methods of practice. NIST publi

- Page 268 and 269: Table 7.1 NSUAA Summary of State Re

- Page 270 and 271: New Surveys of State Agencies and W

- Page 272 and 273: the AWWA WaterStats 1999 database.

- Page 274 and 275: Measures, which dispatches a public

- Page 276 and 277: Mississippi, Missouri, Pennsylvania

- Page 278 and 279: 226 Table 7.6 Summary of utility re

- Page 280 and 281: DISCUSSION - KEY EXAMPLES OF STATE

- Page 282 and 283: ill. Condominium associations are g

- Page 284 and 285: under construction after January 1,

- Page 286 and 287: Weights and Measures Regulation In

- Page 288 and 289: from the submetering. Meter testing

- Page 290 and 291: clean and decent housing or the lac

- Page 292 and 293: 240

- Page 294 and 295: NATIONAL ORGANIZATIONAL STRUCTURE F

- Page 296 and 297: complaints in all 50 states and app

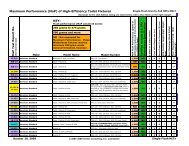

- Page 298 and 299: - Meters must demonstrate in testin

- Page 302 and 303: (2) Twisted or kinked flex supply l

- Page 304 and 305: 252

- Page 306 and 307: Estimated Water Use By Different Bi

- Page 308 and 309: there are clear benefits to these s

- Page 310 and 311: study site. These values were then

- Page 312 and 313: immediately strengthens the owner's

- Page 314 and 315: among the nation's key strategies f

- Page 316 and 317: all repair and replacement decision

- Page 318 and 319: These findings underscore the obser

- Page 320 and 321: varies with volume of use) for mult

- Page 322 and 323: Recommendation 6 - Efficient plumbi

- Page 324 and 325: financially responsible for their o

- Page 326 and 327: individual unit, the volume allocat

- Page 328 and 329: RECOMMENDATIONS FOR FURTHER RESEARC

- Page 330 and 331: Fixed rates - Part of a master mete

- Page 332 and 333: Total-capture submetering - a type

- Page 334 and 335: 282

- Page 336 and 337: Corral, L.R. 1997. Price and Non-Pr

- Page 338 and 339: McClelland, L. 1980. Encouraging En

- Page 340: Young, C.E., K.R. Kinsley and W.E.