F4200N Manual - Fisnar.fr

F4200N Manual - Fisnar.fr

F4200N Manual - Fisnar.fr

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

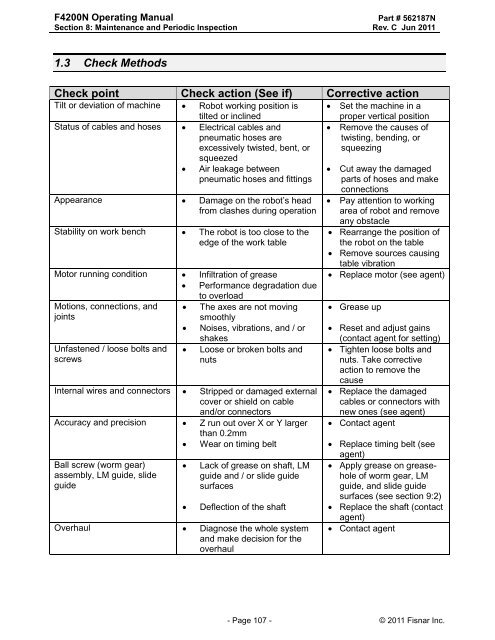

<strong>F4200N</strong> Operating <strong>Manual</strong><br />

Section 8: Maintenance and Periodic Inspection<br />

Part # 562187N<br />

Rev. C Jun 2011<br />

1.3 Check Methods<br />

Check point Check action (See if) Corrective action<br />

Tilt or deviation of machine Robot working position is<br />

tilted or inclined<br />

Status of cables and hoses Electrical cables and<br />

pneumatic hoses are<br />

excessively twisted, bent, or<br />

squeezed<br />

Air leakage between<br />

pneumatic hoses and fittings<br />

Appearance Damage on the robot‟s head<br />

<strong>fr</strong>om clashes during operation<br />

Stability on work bench The robot is too close to the<br />

edge of the work table<br />

Motor running condition Infiltration of grease<br />

Performance degradation due<br />

to overload<br />

Motions, connections, and The axes are not moving<br />

joints<br />

smoothly<br />

Noises, vibrations, and / or<br />

shakes<br />

Unfastened / loose bolts and Loose or broken bolts and<br />

screws<br />

nuts<br />

Internal wires and connectors Stripped or damaged external<br />

cover or shield on cable<br />

and/or connectors<br />

Accuracy and precision Z run out over X or Y larger<br />

than 0.2mm<br />

Wear on timing belt<br />

Ball screw (worm gear)<br />

assembly, LM guide, slide<br />

guide<br />

<br />

<br />

Lack of grease on shaft, LM<br />

guide and / or slide guide<br />

surfaces<br />

Deflection of the shaft<br />

Overhaul Diagnose the whole system<br />

and make decision for the<br />

overhaul<br />

Set the machine in a<br />

proper vertical position<br />

Remove the causes of<br />

twisting, bending, or<br />

squeezing<br />

Cut away the damaged<br />

parts of hoses and make<br />

connections<br />

Pay attention to working<br />

area of robot and remove<br />

any obstacle<br />

Rearrange the position of<br />

the robot on the table<br />

Remove sources causing<br />

table vibration<br />

Replace motor (see agent)<br />

Grease up<br />

Reset and adjust gains<br />

(contact agent for setting)<br />

Tighten loose bolts and<br />

nuts. Take corrective<br />

action to remove the<br />

cause<br />

Replace the damaged<br />

cables or connectors with<br />

new ones (see agent)<br />

Contact agent<br />

Replace timing belt (see<br />

agent)<br />

Apply grease on greasehole<br />

of worm gear, LM<br />

guide, and slide guide<br />

surfaces (see section 9:2)<br />

Replace the shaft (contact<br />

agent)<br />

Contact agent<br />

- Page 107 - © 2011 <strong>Fisnar</strong> Inc.