- Page 1 and 2:

Free dissemination (Contract TREN/D

- Page 3 and 4:

TABLE OF CONTENTS 0 EXECUTIVE SUMMA

- Page 5 and 6:

6.1.7 Intelligent electronic dimmab

- Page 7 and 8:

LIST OF TABLES Table 1: Simplified

- Page 9 and 10:

Table 68: Category S (slow traffic)

- Page 11 and 12:

Table 144: Overview of ‘Mercury v

- Page 13 and 14:

LIST OF FIGURES Figure 1: Typical s

- Page 15:

Figure 69: Value of lamp production

- Page 18 and 19:

even the luminaire in its entirety

- Page 21 and 22:

1 PRODUCT DEFINITION The goal of th

- Page 23 and 24:

Figure 3: Typical street lighting l

- Page 25 and 26:

• Products such as private outdoo

- Page 27 and 28:

Figure 8: Example of Fast Traffic (

- Page 29 and 30:

“The maintained useful luminous f

- Page 31 and 32:

The two following characters indica

- Page 33 and 34:

parameters influencing the deprecia

- Page 35 and 36:

sum of the individual luminous flux

- Page 37 and 38:

This part of the European Standard

- Page 39 and 40:

(compact) lamps with power equal to

- Page 41 and 42:

Specifies the lamp dimensions, elec

- Page 43 and 44:

Specifies the safety requirements f

- Page 45 and 46:

Exceptions for lamps: this directiv

- Page 47 and 48:

Catalonia 2001: 'LLEI 6/2001, de 31

- Page 49 and 50:

Table 3: Mandatory Label for Ballas

- Page 51 and 52:

Table 7: Voluntary Label for Ballas

- Page 53 and 54:

2 MARKET AND ECONOMIC ANALYSIS The

- Page 55 and 56:

Millions of lamps 45,0 40,0 35,0 30

- Page 57 and 58:

parts no information on production

- Page 59 and 60:

Table 149 and Table 150 in ANNEX E

- Page 61 and 62:

Table 10: Overview of lamp and ball

- Page 63 and 64:

2.2 Market and stock data To overco

- Page 65 and 66:

An introduction message explained t

- Page 67 and 68:

Table 156 and Figure 14 indicate th

- Page 69 and 70:

pronounced, i.e. the apparent consu

- Page 71 and 72:

Road category Road length in 2004 S

- Page 73 and 74:

For luminaires we can conclude that

- Page 75 and 76:

causes higher currents and by conse

- Page 77 and 78: 2005 Luminaires TOTAL %EU25 Capita

- Page 79 and 80: As will be explained in chapter 3 o

- Page 81 and 82: 2.3 Market trends 2.3.1 General tre

- Page 83 and 84: manufacturers have dominated the in

- Page 85 and 86: 2.4 Consumer expenditure data 2.4.1

- Page 87 and 88: Public street lighting is mainly op

- Page 89 and 90: 3 CONSUMER BEHAVIOUR AND LOCAL INFR

- Page 91 and 92: Table 22: Relationship between phot

- Page 93 and 94: 4. Dimming to compensate for Lamp L

- Page 95 and 96: can overcome this problem. This pow

- Page 97 and 98: generation of gas discharge lamps i

- Page 99 and 100: clear that light point locations ca

- Page 101 and 102: with, Lav = QO x Eavg Table 28: Ave

- Page 103 and 104: times the height. In category S, th

- Page 105 and 106: ageing of the overall population wi

- Page 107 and 108: 4 TECHNICAL ANALYSIS EXISTING PRODU

- Page 109 and 110: lamps. It is unlikely that this wil

- Page 111 and 112: Table 34: Input data for the manufa

- Page 113 and 114: Table 37: Input data for the materi

- Page 115 and 116: The general remarks about this inpu

- Page 117 and 118: Table 43: Input data for the materi

- Page 119 and 120: Table 45: Input data for the materi

- Page 121 and 122: With regard to the different parts

- Page 123 and 124: Table 49: Input data for the materi

- Page 125 and 126: Table 53: Input data for the materi

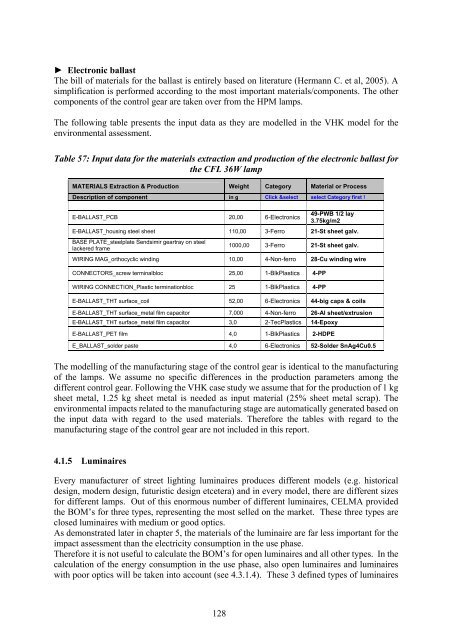

- Page 127: Table 55: Input data for the materi

- Page 131 and 132: 4.2 Distribution phase The environm

- Page 133 and 134: distance between light points is be

- Page 135 and 136: Until now, existing scientific evid

- Page 137 and 138: The energy efficiency in the use-ph

- Page 139 and 140: Table 66: Category S (slow traffic)

- Page 141 and 142: The real power consumption (Preal)

- Page 143 and 144: Figure 24: A high amount of light i

- Page 145 and 146: LPDireal [W/(lx.m²)] = P / LPDi /

- Page 147 and 148: 5 DEFINITION OF THE BASE CASE AND E

- Page 149 and 150: This results in the following EuP E

- Page 151 and 152: 5.1 BaseCase Lamps and ballasts 5.1

- Page 153 and 154: Category S In road category S (slow

- Page 155 and 156: Table 76: Life Cycle Impact per Bas

- Page 157 and 158: Table 78: Life Cycle Impact per Bas

- Page 159 and 160: the higher weight of the control ge

- Page 161 and 162: Table 80: Aggregated Production, Di

- Page 163 and 164: 5.3 BaseCase Sales The results in t

- Page 165 and 166: 5.3.2 Environmental Impact On www.e

- Page 167 and 168: Table 84: Life Cycle Impact, Base C

- Page 169 and 170: Table 86: Life Cycle Impact, Base C

- Page 171 and 172: Table 88: Life Cycle Impact, Base C

- Page 173 and 174: Table 90: Life Cycle Impact, Base C

- Page 175 and 176: 5.3.3 BaseCase Life Cycle Costs The

- Page 177 and 178: Table 93: EU Total Impact of NEW Lu

- Page 179 and 180:

Discussion of results Again, EU25 t

- Page 181 and 182:

5.4.2 Environmental Impact Table 96

- Page 183 and 184:

Table 98: Life Cycle Impact, Base C

- Page 185 and 186:

Table 100: Life Cycle Impact, Base

- Page 187 and 188:

Table 102: Impacts sales versus sto

- Page 189 and 190:

6 TECHNICAL ANALYSIS BAT AND BNAT S

- Page 191 and 192:

6.1.3 Luminaires with improved util

- Page 193 and 194:

there is an increased reflection on

- Page 195 and 196:

MH lamps can have a quite short lam

- Page 197 and 198:

Table 105: LSF for various lamp typ

- Page 199 and 200:

The energy saving advantages of dim

- Page 201 and 202:

6.2 State of the art of best existi

- Page 203 and 204:

6.3.3 WLEDs lamps Figure 37: Typica

- Page 205 and 206:

7 IMPROVEMENT POTENTIAL 7.1 Introdu

- Page 207 and 208:

Option 1 (stock base): HPS retrofit

- Page 209 and 210:

• This option is only technically

- Page 211 and 212:

7.2.4 Table with EuP EcoReports for

- Page 213 and 214:

LCC in €/1000f-lm 300 250 200 150

- Page 215 and 216:

cost indicator (LCC) low high cost

- Page 217 and 218:

comfort of outdoor lighting, the fi

- Page 219 and 220:

8 SCENARIO-, POLICY-, IMPACT- AND S

- Page 221 and 222:

• For lamps with Ra < 80 power ba

- Page 223 and 224:

Burning hours LLMF 16000h >0.90 Bur

- Page 225 and 226:

Proposed timing: ASAP because these

- Page 227 and 228:

8.1.1.12 Specific ecodesign require

- Page 229 and 230:

Table 107: Aggregated results, Busi

- Page 231 and 232:

Table 111: Annual lamp sales, per c

- Page 233 and 234:

EU25 electricity consumption, altho

- Page 235 and 236:

Table 116: Aggregated results, Scen

- Page 237 and 238:

€ increase. The increase between

- Page 239 and 240:

500 450 400 350 300 250 200 150 100

- Page 241 and 242:

40.000 35.000 30.000 25.000 20.000

- Page 243 and 244:

Table 126: LCC of luminaire sales i

- Page 245 and 246:

45000 40000 35000 30000 25000 20000

- Page 247 and 248:

anking is from uncertainty in purch

- Page 249 and 250:

Uncertainty regarding assumed watta

- Page 251 and 252:

Table 131: Forecast of installed ba

- Page 253 and 254:

Table 133: Aggregated results, Busi

- Page 255 and 256:

taking into account pole removal an

- Page 257 and 258:

Recommendation 3: It is also recomm

- Page 259 and 260:

8.2 Impact analysis industry and co

- Page 261 and 262:

existing installations could even i

- Page 263 and 264:

9 REFERENCES AFE (2002) Recommandat

- Page 265 and 266:

CIE 135-1999: CIE Collection in vis

- Page 267 and 268:

Eurostat (2006). Road lengths of di

- Page 269 and 270:

10 ABBREVIATIONS and ACRONYMS Abbre

- Page 271 and 272:

IESNA ILCOS IP (rating) IRF ISO L L

- Page 273 and 274:

ANNEX A: PRODCOM CATEGORIES OF LIGH

- Page 275 and 276:

ANNEX B: EUROPROMS RESULTS FOR LAMP

- Page 277 and 278:

Year Region Table 141: Mercury vapo

- Page 279 and 280:

ANNEX C: OVERVIEW OF PRODUCTION, TR

- Page 281 and 282:

ANNEX D: EUROPROMS RESULTS FOR BALL

- Page 283 and 284:

Table 148: Parts (excluding of glas

- Page 285 and 286:

ANNEX E: OVERVIEW OF PRODUCTION, TR

- Page 287 and 288:

ANNEX F: EUROPROMS RESULTS FOR LUMI

- Page 289 and 290:

ANNEX G: OVERVIEW OF LAMP AND BALLA

- Page 291 and 292:

Millions of ballasts 600 500 400 30

- Page 293 and 294:

ANNEX H: EXPERT-INQUIRY Preparatory

- Page 295 and 296:

You can already register for Office

- Page 297 and 298:

Road types In our study, we disting

- Page 299 and 300:

General street lighting data - Inst

- Page 301 and 302:

6. Can you give us an estimation ab

- Page 303 and 304:

Standardization of public lighting

- Page 305 and 306:

Roads lit and control 15. What perc

- Page 307 and 308:

Road infrastructure 19. Can you giv

- Page 309 and 310:

Street lighting: Maintenance 22. Is

- Page 311 and 312:

Lamp type NaLP-TC (Low pressure sod

- Page 313 and 314:

lamp type wattage past present futu

- Page 315 and 316:

luminaire type default 1990 adapted

- Page 317 and 318:

ANNEX I: RESPONSE TO “EXPERT-INQU

- Page 319 and 320:

ANNEX J: EU-25 LAMP SALES Table 156

- Page 321 and 322:

ANNEX K: APPARENT CONSUMPTION VERSU

- Page 323 and 324:

Table 160: Apparent consumption of

- Page 325 and 326:

ANNEX L: CELMA MARKET ESTIMATIONS T

- Page 327 and 328:

ANNEX M: INSTALLED BASE OF STREET L

- Page 329 and 330:

ANNEX N: EUROPEAN ROAD NETWORK: 199

- Page 331 and 332:

Table 164: Length of European provi

- Page 333 and 334:

Table 166: Input data regarding roa

- Page 335 and 336:

ANNEX O: EU ROAD INFRASTRUCTURE PRO

- Page 337 and 338:

Economic growth is not uniformly di

- Page 339 and 340:

ANNEX P: STAKEHOLDERS’ LIST First

- Page 341 and 342:

FOTISTIKI SA Pakis Sotiropoulos Gre

- Page 343 and 344:

Large control street office Philips