naval dockyard, mumbai - Irfc-nausena.nic.in

naval dockyard, mumbai - Irfc-nausena.nic.in

naval dockyard, mumbai - Irfc-nausena.nic.in

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

iii) Perished wir<strong>in</strong>g / cable / total wir<strong>in</strong>g to be replaced<br />

as per order/ requirement OEM specified .<br />

(iv) Cable samples to be approved from QC prior to<br />

fitment & should be IS 694/1554 confirm<strong>in</strong>g LFHR<br />

/LFH /FR wires 1100Volts. For control wir<strong>in</strong>g<br />

m<strong>in</strong>imum 1.5 / 2.5 sq mm cables for power cables<br />

defend upon current rat<strong>in</strong>g/requirement / OEM<br />

specified / Navy order. (v) Check for control cables<br />

term<strong>in</strong>ation to be done by t<strong>in</strong>ned copper lugs with<br />

appropriate current rat<strong>in</strong>g with heat shr<strong>in</strong>k sleeve /<br />

PVC sleeve with number<strong>in</strong>g as per draw<strong>in</strong>g. Lugs :<br />

Dowell’s make. (vi) Check for replacement of<br />

exist<strong>in</strong>g cables as per sample / Current and voltage<br />

rat<strong>in</strong>g.<br />

(vii) Check for all laid cables secured and lay out<br />

properly. Power and control cables shall be neatly<br />

bunched separately (viii) Check for number<strong>in</strong>g to all<br />

cables ends as per Circuit Diagrams. (ix) As per IS<br />

standard Bus bar should be t<strong>in</strong>ned / electroplated<br />

and heat shr<strong>in</strong>k sleeve to be covered on the bus bar.<br />

Bus bar to be used as per current rat<strong>in</strong>g requirement.<br />

NAVAL DOCKYARD, MUMBAI<br />

TITLE : QUALITY ASSURANCE PLAN DOC CODE Q C L 7 4 Q A P 0 6 3<br />

DEPT. :<br />

QC(ELECTRICAL )<br />

C. NO. 74 ISSUE NO : 00 DATE : 15 Apr 12 PAGE 12 OF 14<br />

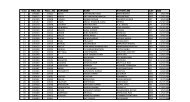

Sr.<br />

No.<br />

ACTIVITY<br />

DESCRIPTION<br />

REFERENCE DOCMENT & CHECK LIST INSPECTION<br />

SCOPE OF WORK P R W H<br />

(i) Check and confirm for make, model, type, design 1 2&3 3 3<br />

and capacity of controller. Check for Type, rat<strong>in</strong>g &<br />

model of controller, current capacity. .<br />

(ii) Check for serviceability of controller & Drum<br />

controller for to ascerta<strong>in</strong> the serviceability of each<br />

24 Controller & Drum<br />

Controller<br />

DYT/INCOD/1213/106(a)/PLYCM/MADHURREFIT/420 78/127

![DGNP[V] - Irfc-nausena.nic.in](https://img.yumpu.com/23509938/1/158x260/dgnpv-irfc-nausenanicin.jpg?quality=85)