Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

Evaluation of Permeability of Masterbatch-Based PA6/nanoclay Composite Films<br />

1<br />

1<br />

UMohammad FasihiUP0F P*and Mohammad Reza Abolghasemi0TP<br />

Technology of Polymer Research Group, Iranian Academic Center for Education, Culture and Research (ACECR), Branch of Amirkabir<br />

University of Technology, Tehran, Iran,<br />

Abstract-This study focuses on the effect of the nanoclay masterbatch on the extent of exfoliation and barrier properties of PA6/organoclay<br />

nanocomposite films. Gas permeability through nanocomposite films decreased significantly just by loading a small amount of nanoclay.<br />

Theoretical models fit the experimental data appropriately.<br />

Over the last decades, a great deal of researches have been<br />

devoted to the different fields of polymer-layered silicate<br />

nanocomposites which have shown promising improvements<br />

[1-3]<br />

in properties, at low filler volume fraction.P<br />

One of the great attractive applications of polymer-layered<br />

silicate nanocomposites is the field of packaging. The<br />

reduction of oxygen permeability is of crucial importance<br />

since oxygen as an atmospheric component which promotes<br />

the spoilage mechanism of food. Incorporating layered silicate<br />

into the polymeric matrix, ordinarily, improves gas barrier<br />

properties of the polymer by reducing the volume available for<br />

gas transport as well as making a more tortuous path for<br />

[4-6]<br />

penetrant molecules. P<br />

The current study examined the effect of nanoclay<br />

dispersion by using particulate nanoclay and nanoclay<br />

masterbatch, on morphology and oxygen permeability of<br />

polyamide-6 /layered silicate nanocomposite films bearing<br />

different concentrations of nanoclay, as a potential candidate<br />

for good packaging applications. Furthermore, the<br />

permeability data has also been compared to the theoretical<br />

models.<br />

XRD results showed flat diffraction profile and the absence<br />

of any basal reflections indicated that the ordered layers of<br />

nanoclays in the nanocomposites have been disrupted.<br />

With regards to the crystalline structure, all films exhibited a<br />

o<br />

strong reflection at 21.5P distinguished t <br />

crystal form which showed that the loading of nanoclay did<br />

not alter crystal structures in thin films.<br />

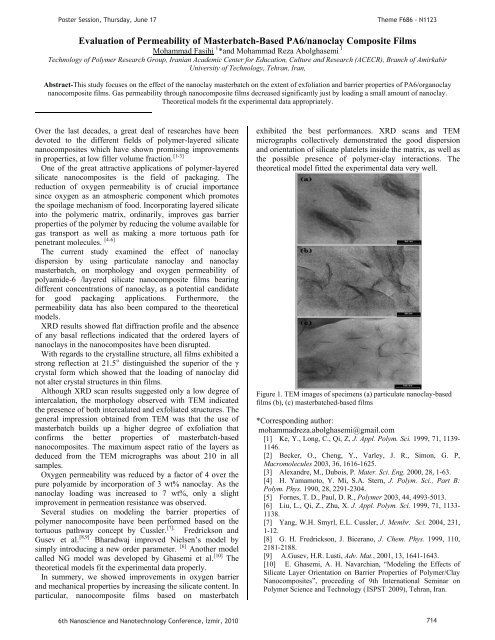

Although XRD scan results suggested only a low degree of<br />

intercalation, the morphology observed with TEM indicated<br />

the presence of both intercalated and exfoliated structures. The<br />

general impression obtained from TEM was that the use of<br />

masterbatch builds up a higher degree of exfoliation that<br />

confirms the better properties of masterbatch-based<br />

nanocomposites. The maximum aspect ratio of the layers as<br />

deduced from the TEM micrographs was about 210 in all<br />

samples.<br />

Oxygen permeability was reduced by a factor of 4 over the<br />

pure polyamide by incorporation of 3 wt% nanoclay. As the<br />

nanoclay loading was increased to 7 wt%, only a slight<br />

improvement in permeation resistance was observed.<br />

Several studies on modeling the barrier properties of<br />

polymer nanocomposite have been performed based on the<br />

[7],<br />

tortuous pathway concept by Cussler.P Fredrickson and<br />

[8,9]<br />

Gusev et al.P Bharadwaj improved Nielsen’s model by<br />

[6]<br />

simply introducing a new order parameter. P Another model<br />

[10]<br />

called NG model was developed by Ghasemi et al.P<br />

PThe<br />

theoretical models fit the experimental data properly.<br />

In summery, we showed improvements in oxygen barrier<br />

and mechanical properties by increasing the silicate content. In<br />

particular, nanocomposite films based on masterbatch<br />

exhibited the best performances. XRD scans and TEM<br />

micrographs collectively demonstrated the good dispersion<br />

and orientation of silicate platelets inside the matrix, as well as<br />

the possible presence of polymer-clay interactions. The<br />

theoretical model fitted the experimental data very well.<br />

Figure 1. TEM images of specimens (a) particulate nanoclay-based<br />

films (b), (c) masterbatched-based films<br />

*Corresponding author:<br />

mohammadreza.abolghasemi@gmail.com<br />

[1] Ke, Y., Long, C., Qi, Z, J. Appl. Polym. Sci. 1999, 71, 1139-<br />

1146.<br />

[2] Becker, O., Cheng, Y., Varley, J. R., Simon, G. P,<br />

Macromolecules 2003, 36, 1616-1625.<br />

[3] Alexandre, M., Dubois, P. Mater. Sci. Eng. 2000, 28, 1-63.<br />

[4] H. Yamamoto, Y. Mi, S.A. Stern, J. Polym. Sci., Part B:<br />

Polym. Phys. 1990, 28, 2291-2304.<br />

[5] Fornes, T. D., Paul, D. R., Polymer 2003, 44, 4993-5013.<br />

[6] Liu, L., Qi, Z., Zhu, X. J. Appl. Polym. Sci. 1999, 71, 1133-<br />

1138.<br />

[7] Yang, W.H. Smyrl, E.L. Cussler, J. Membr. Sci. 2004, 231,<br />

1-12.<br />

[8] G. H. Fredrickson, J. Bicerano, J. Chem. Phys. 1999, 110,<br />

2181-2188.<br />

[9] A.Gusev, H.R. Lusti, Adv. Mat., 2001, 13, 1641-1643.<br />

[10] E. Ghasemi, A. H. Navarchian, “Modeling the Effects of<br />

Silicate Layer Orientation on Barrier Properties of Polymer/Clay<br />

Nanocomposites”, proceeding of 9th International Seminar on<br />

Polymer Science and Technology (3TISPST3T 2009), Tehran, Iran.<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 714