Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

Undesired Phase Formations Between Ba 0.5 Sr 0.5 Co 0.8 Fe 0.2 O 3-δ Cathode and La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 O 2.85<br />

Electrolyte for SOFCs<br />

Yeliz EKINCI 1 , Ridvan DEMIRYUREK 2* , Omer KARAKOC 2* , Shalima SHAWUTI 2 , Cinar ONCEL 2 and M. Ali GULGUN 2<br />

1 Faculty of Chemical and Metallurgical Engineering, Istanbul Technical University, Istanbul 34469, Turkey<br />

2 Faculty of Engineering and Natural Sciences, Sabanci University, Istanbul 34956, Turkey<br />

Abstract Ba 0.5 Sr 0.5 Co 0.8 Fe 0.2 O 3-δ (BSCF) is promising material as a cathode for La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 O 2.85 (LSGM) based SOFCs. For this aim,<br />

BSCF-LSGM powders were characterized by the XRD, SEM and EDS techniques to observe the formation of undesired phases in the<br />

temperature range of 700-1100 °C. Formation of new phases began around 900 °C. No new phases were observed below this temperature.<br />

SrLaGa 3 O 7 , BaLaGaO 4 and Ba 6 La 2 Co 4 O 15 could be undesired phases which were strongly observed at 1100 °C.<br />

The main obstacle in front of SOFC’s commercialization<br />

is their high operating temperatures [1]. Efforts to reduce the<br />

operating temperature brings along some problems with them.<br />

There is a substantial increase in electrochemical resistance of<br />

the fuel cell components (anode, cathode and electrolyte) and<br />

an increase of electrode polarization resistance [2]. To tackle<br />

these problems, novel materials has been under an intense<br />

studies. Ba 0.5 Sr 0.5 Co 0.8 Fe 0.2 O 3−δ (BSCF) cathode and<br />

La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 O 2.85 (LSGM) electrolyte material<br />

combination offers promising results. LSGM is preferred<br />

because of its high oxygen ion conductivity, 10 -1 S cm -1 [3] at<br />

800 °C and high oxygen diffusion rate. The electronic<br />

conductivity pattern over a wide range of oxygen partial<br />

pressures (10 − 20 to 1 atm) can be assumed negligible at<br />

intermediate operating temperatures [3]. BSCF is a mixed<br />

oxygen ionic and electronic conducting oxide in the lattice<br />

form of perovskite [2]. High activity to reduce the oxygen<br />

electrochemically and high oxygen diffusion rate at 773-873<br />

°C makes BSCF worthy of investigation [3]. However use of<br />

BSCF cathode and LSGM electrolyte together may cause<br />

formation of some undesired phases. These undesired phases<br />

could decrease the efficiency of the whole system.<br />

In this investigation, the temperature range at which<br />

undesired reactions between the cathode candidate and the<br />

LSGM electrolyte take place and the phases that are formed<br />

were studied. BSCF used in this study was synthesized by<br />

combined EDTA-citrate (EC) method [4]. The temperature of<br />

the formation of reaction products was determined by XRD.<br />

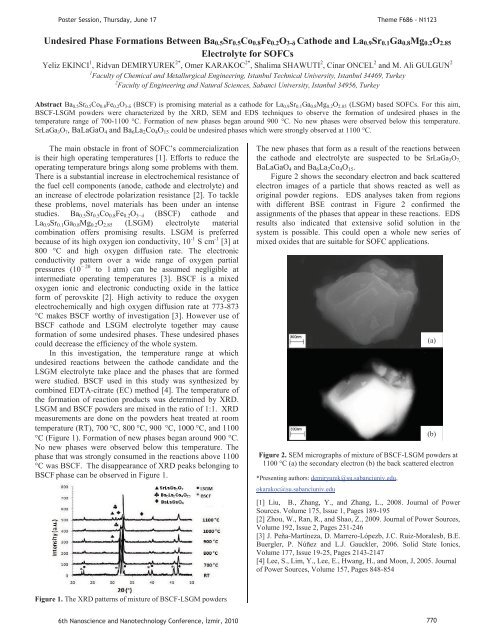

LSGM and BSCF powders are mixed in the ratio of 1:1. XRD<br />

measurements are done on the powders heat treated at room<br />

temperature (RT), 700 C, 800 C, 900 C, 1000 C, and 1100<br />

C (Figure 1). Formation of new phases began around 900 C.<br />

No new phases were observed below this temperature. The<br />

phase that was strongly consumed in the reactions above 1100<br />

°C was BSCF. The disappearance of XRD peaks belonging to<br />

BSCF phase can be observed in Figure 1.<br />

The new phases that form as a result of the reactions between<br />

the cathode and electrolyte are suspected to be SrLaGa 3 O 7,<br />

BaLaGaO 4 and Ba 6 La 2 Co 4 O 15 .<br />

Figure 2 shows the secondary electron and back scattered<br />

electron images of a particle that shows reacted as well as<br />

original powder regions. EDS analyses taken from regions<br />

with different BSE contrast in Figure 2 confirmed the<br />

assignments of the phases that appear in these reactions. EDS<br />

results also indicated that extensive solid solution in the<br />

system is possible. This could open a whole new series of<br />

mixed oxides that are suitable for SOFC applications.<br />

Figure 2. SEM micrographs of mixture of BSCF-LSGM powders at<br />

1100 °C (a) the secondary electron (b) the back scattered electron<br />

*Presenting authors: demiryurek@su.sabanciuniv.edu,<br />

okarakoc@su.sabanciuniv.edu<br />

[1] Liu, B., Zhang, Y., and Zhang, L., 2008. Journal of Power<br />

Sources. Volume <strong>17</strong>5, Issue 1, Pages 189-195<br />

[2] Zhou, W., Ran, R., and Shao, Z., 2009. Journal of Power Sources,<br />

Volume 192, Issue 2, Pages 231-246<br />

[3] J. Peña-Martíneza, D. Marrero-Lópezb, J.C. Ruiz-Moralesb, B.E.<br />

Buergler, P. Núñez and L.J. Gauckler, 2006. Solid State Ionics,<br />

Volume <strong>17</strong>7, Issue 19-25, Pages 2143-2147<br />

[4] Lee, S., Lim, Y., Lee, E., Hwang, H., and Moon, J, 2005. Journal<br />

of Power Sources, Volume 157, Pages 848-854<br />

(a)<br />

(b)<br />

Figure 1. The XRD patterns of mixture of BSCF-LSGM powders<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 770