Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

Morphology of the Electrospun Nylon-66 and Polybutylene terephthalate Nanofibers<br />

Fatma Kayacı and Tamer Uyar*<br />

UNAM-Institute of Materials Science & Nanotechnology, Bilkent University, Ankara, 06800, Turkey<br />

Abstract – This work covers our recent studies on fabrication of polymeric nanofibers by electrospinning technique.<br />

Nanofibers/nanowebs of Nylon-66 (PA66) and Polybutylene terephthalate (PBT) have been obtained by electrospinning and<br />

the morphology of the resulting nanofibers/nanowebs was investigated by scanning electron microscope (SEM) .<br />

Electrospinning is the most versatile method for<br />

fabrication of nanofibers, since it is a simple and<br />

cost effective technique. The nanofibers can be<br />

electrospun from a wide range of polymers that are<br />

soluble in various solvent systems. In addition, the<br />

ability to produce nanofibers/nanowebs which have<br />

unique properties like small pore size, large surface<br />

area to volume ratio, high porosity make<br />

electrospun nanofibers more attractive for many<br />

applications such as filtration, textile, tissue<br />

engineering, wound healing, release control,<br />

sensors, energy, etc [1-6]. Electrospinning is a<br />

simple process in which a polymer solution or melt<br />

is subjected to high voltage (10 kv- 60 kv) and the<br />

fibers which have diameter in the range of few<br />

microns to few hundred nanometers are produced in<br />

the form of nonwoven [4-8].<br />

Nylon-66 is an important semi-crystalline<br />

thermoplastic polymer having mechanical strength,<br />

chemical resistance, toughness, and dimensional<br />

stability. Therefore, nylon-66 is one of the most<br />

used polymers for numerous applications such as<br />

technical texiles, filtration, and especially<br />

engineering field [7,8]. Polybutylene terephthalate<br />

(PBT), a linear polyester of aromatic nature, is also<br />

one of the important engineering plastics due to its<br />

good mechanical, and thermal properties [9].<br />

In this study, Nylon 66 and PBT<br />

nanofibers/nanowebs were obtained by<br />

electrospinning. Formic acid/chloroform (75/25)<br />

and hexafluoroisopropanol (HFIP) were used as<br />

solvent for Nylon-66 and PBT, respectively.<br />

Polymer concentration, tip-to-collector distance and<br />

applied voltage were optimized in order to obtain<br />

bead-free uniform nanofibers.<br />

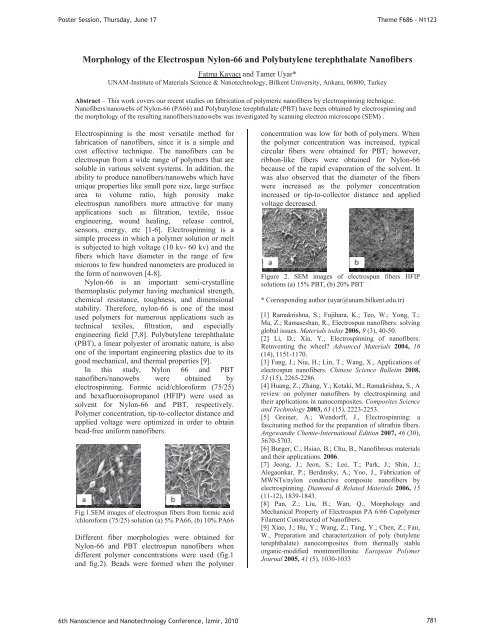

Fig.1.SEM images of electrospun fibers from formic acid<br />

/chloroform (75/25) solution (a) 5% PA66, (b) 10% PA66<br />

Different fiber morphologies were obtained for<br />

Nylon-66 and PBT electrospun nanofibers when<br />

different polymer concentrations were used (fig.1<br />

and fig.2). Beads were formed when the polymer<br />

concentration was low for both of polymers. When<br />

the polymer concentration was increased, typical<br />

circular fibers were obtained for PBT; however,<br />

ribbon-like fibers were obtained for Nylon-66<br />

because of the rapid evaporation of the solvent. It<br />

was also observed that the diameter of the fibers<br />

were increased as the polymer concentration<br />

increased or tip-to-collector distance and applied<br />

voltage decreased.<br />

Figure 2. SEM images of electrospun fibers HFIP<br />

solutions (a) 15% PBT, (b) 20% PBT<br />

* Corresponding author (uyar@unam.bilkent.edu.tr)<br />

[1] Ramakrishna, S.; Fujihara, K.; Teo, W.; Yong, T.;<br />

Ma, Z.; Ramaseshan, R., Electrospun nanofibers: solving<br />

global issues. Materials today 2006, 9 (3), 40-50.<br />

[2] Li, D.; Xia, Y., Electrospinning of nanofibers:<br />

Reinventing the wheel? Advanced Materials 2004, 16<br />

(14), 1151-1<strong>17</strong>0.<br />

[3] Fang, J.; Niu, H.; Lin, T.; Wang, X., Applications of<br />

electrospun nanofibers. Chinese Science Bulletin 2008,<br />

53 (15), 2265-2286.<br />

[4] Huang, Z.; Zhang, Y.; Kotaki, M.; Ramakrishna, S., A<br />

review on polymer nanofibers by electrospinning and<br />

their applications in nanocomposites. Composites Science<br />

and Technology 2003, 63 (15), 2223-2253.<br />

[5] Greiner, A.; Wendorff, J., Electrospinning: a<br />

fascinating method for the preparation of ultrathin fibers.<br />

Angewandte Chemie-International Edition 2007, 46 (30),<br />

5670-5703.<br />

[6] Burger, C.; Hsiao, B.; Chu, B., Nanofibrous materials<br />

and their applications. 2006.<br />

[7] Jeong, J.; Jeon, S.; Lee, T.; Park, J.; Shin, J.;<br />

Alegaonkar, P.; Berdinsky, A.; Yoo, J., Fabrication of<br />

MWNTs/nylon conductive composite nanofibers by<br />

electrospinning. Diamond & Related Materials 2006, 15<br />

(11-12), 1839-1843.<br />

[8] Pan, Z.; Liu, H.; Wan, Q., Morphology and<br />

Mechanical Property of Electrospun PA 6/66 Copolymer<br />

Filament Constructed of Nanofibers.<br />

[9] Xiao, J.; Hu, Y.; Wang, Z.; Tang, Y.; Chen, Z.; Fan,<br />

W., Preparation and characterization of poly (butylene<br />

terephthalate) nanocomposites from thermally stable<br />

organic-modified montmorillonite. European Polymer<br />

Journal 2005, 41 (5), 1030-1033<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 781