Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

P ions<br />

P<br />

P have<br />

P contact<br />

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

The Creation of Hydrophobic Clay Surfaces with Long Chain Hydrocarbon<br />

1<br />

1<br />

1<br />

UH. Hasan YolcuUP P*, Ahmet GürsesP P, and Metin AçkyldzP P,<br />

1<br />

PAtaturk University, K.K. Education Faculty, Dep. of Chemistry, 25240 Erzurum<br />

Abstract- In this study, the presence of lotus effect for the clay modified by using long chain hydrocarbon was investigated. It was<br />

found the powder sample comparison with pellet form exhibits super hydrophobic character. This may be attributed to the changing of<br />

roughness on the surface of modified clay particles depending on pressing and to the creating of higher energy surface with the adsorption of<br />

long chain hydrocarbon onto interlayer region of clay.<br />

Non wettable surfaces with high water contact angle<br />

(WCA) and facile sliding of drops are called super<br />

hydrophobic surface. Superhydrophobic surfaces with<br />

0<br />

water contact angles larger than 150P received a lot<br />

of research attention, due to important applications ranging<br />

from self cleaning materials to microfluidic devices [1, 2].<br />

Many surfaces in nature are highly hydrophobic and self<br />

cleaning (e.g. lotus leaves). The design synthesis and<br />

application of new kinds of super hydrophobic and self<br />

cleaning organic or inorganic material will be essential and<br />

important task to fulfill [3].<br />

The clay sample was purified by sedimentation, dried at<br />

vacuum oven and sieved to give a 38-85 m (>%92) size<br />

fraction using ASTM Standard sieves. Different amounts<br />

of hydrocarbon (0.05-1.0 g) was mixed with 500 mL<br />

aqueous solutions of CTAB (100, 200, 240, 260, 300, and<br />

320 mg/L). The mixture was shaken at 293 K, for 30 mins<br />

and 1g clay sample was added to this mixture and shaken<br />

for 30 mins in a thermostatic shaker at 200 rpm. The<br />

modified clay samples which produced by above<br />

procedure were filtered through filter paper of Whatman<br />

41 and dried at 383 K in a vacuum oven for 2 h.<br />

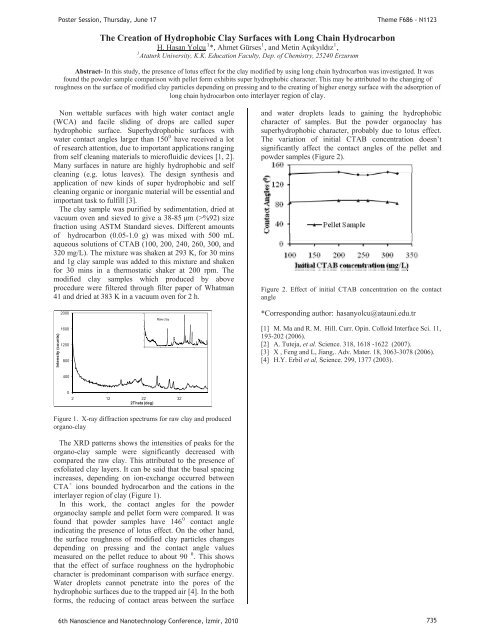

and water droplets leads to gaining the hydrophobic<br />

character of samples. But the powder organoclay has<br />

superhydrophobic character, probably due to lotus effect.<br />

The variation of initial CTAB concentration doesn’t<br />

significantly affect the contact angles of the pellet and<br />

powder samples (Figure 2).<br />

Figure 2. Effect of initial CTAB concentration on the contact<br />

angle<br />

Intensity (counts)<br />

2000<br />

1600<br />

1200<br />

800<br />

Raw clay<br />

*Corresponding author: HThasanyolcu@atauni.edu.trT<br />

[1] M. Ma and R. M. Hill. Curr. Opin. Colloid Interface Sci. 11,<br />

193-202 (2006).<br />

[2] A. Tuteja, et al. Science. 318, 1618 -1622 (2007).<br />

[3] X , Feng and L, Jiang,. Adv. Mater. 18, 3063-3078 (2006).<br />

[4] H.Y. Erbil et al, Science. 299, 1377 (2003).<br />

400<br />

0<br />

2 12 22 32<br />

2Theta (deg)<br />

Figure 1. X-ray diffraction spectrums for raw clay and produced<br />

organo-clay<br />

The XRD patterns shows the intensities of peaks for the<br />

organo-clay sample were significantly decreased with<br />

compared the raw clay. This attributed to the presence of<br />

exfoliated clay layers. It can be said that the basal spacing<br />

increases, depending on ion-exchange occurred between<br />

+<br />

CTAP bounded hydrocarbon and the cations in the<br />

interlayer region of clay (Figure 1).<br />

In this work, the contact angles for the powder<br />

organoclay sample and pellet form were compared. It was<br />

0<br />

found that powder samples have 146P angle<br />

indicating the presence of lotus effect. On the other hand,<br />

the surface roughness of modified clay particles changes<br />

depending on pressing and the contact angle values<br />

0<br />

measured on the pellet reduce to about 90 P P. This shows<br />

that the effect of surface roughness on the hydrophobic<br />

character is predominant comparison with surface energy.<br />

Water droplets cannot penetrate into the pores of the<br />

hydrophobic surfaces due to the trapped air [4]. In the both<br />

forms, the reducing of contact areas between the surface<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 735