Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

P<br />

P<br />

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

1<br />

Effect of Concentration on Roller Electrospinning<br />

1<br />

2<br />

1<br />

UF.YenerUP P*, O.JirsakP P R.GemciP<br />

PTextile Engineering Depatment, Engineering& Architecture Faculty, Kahramanmaras Sutcu Imam University, Campus of Avsar, 46100,<br />

Kahramanmaras, Turkey<br />

2<br />

PNonwoven Department, Textile Engineering Faculty, Technical University of Liberec, Halkova 6, 461<strong>17</strong>, Czech Republic<br />

Abstract- In this study we studied the effect of concentration on Roller Electrospinning Method. Firstly we solved PVB in isopropanol by<br />

using different concentrations as 6%, 7%, 8%, 9%, 10%wt of PVB polymer. Later we compared fiber characteristics for each solvent. We<br />

investigated that fiber diameter increases with increasing of concentration. In higher concentrations, the resultant fibers were more regular.<br />

Nanofibers can be produced from a wide range of<br />

polymers. These fibers have extremely high specific<br />

surface area due to their small diameters, high surface per<br />

weight ratio, good barrier characteristics against the<br />

microorganism and fine particles, high surface energy,<br />

good strength per unit weight, and covering effects, etc [1].<br />

….One of the electrospinning is Nanospider (Roller<br />

Electrospinning) which is the only method for using in<br />

industry nanofibers continuously. This method was<br />

invented by Jirsak in Technical University of Liberec<br />

(Czech Republic), 2003 [2].<br />

In this work, we used Roller Electrospinning with<br />

Polyvinly Butyral (molecular weight of 60,000)<br />

+Isopropanol in different concentrations. These<br />

concentrations were in 6%, 7%, 8%, 9%, 10%wt of PVB.<br />

Conductivity, surface tension, viscosity tests were done.<br />

Increasing the concentration increased the viscosity. Result<br />

of viscosity are shown in figure 1.<br />

6% PVB60+PRO<br />

ƒ = f (Á)<br />

7% PVB60+PRO<br />

ƒ = f (Á)<br />

8% PVB60+PRO<br />

ƒ = f (Á)<br />

9% PVB60+PRO<br />

ƒ = f (Á) 0.50<br />

10% PVB60+PRO<br />

ƒ = f (Á)<br />

0.45<br />

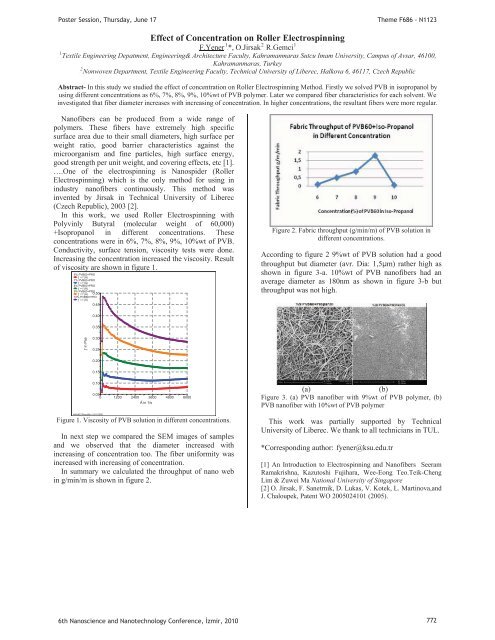

Figure 2. Fabric throughput (g/min/m) of PVB solution in<br />

different concentrations.<br />

According to figure 2 9%wt of PVB solution had a good<br />

throughput but diameter (avr. Dia: 1,5μm) rather high as<br />

shown in figure 3-a. 10%wt of PVB nanofibers had an<br />

average diameter as 180nm as shown in figure 3-b but<br />

throughput was not high.<br />

0.40<br />

0.35<br />

ƒ in Pas<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

HAAKE RheoWin 3.61.0000<br />

0.05<br />

0 1200 2400 3600 4800 6000<br />

Á in 1/s<br />

Figure 1. Viscosity of PVB solution in different concentrations.<br />

In next step we compared the SEM images of samples<br />

and we observed that the diameter increased with<br />

increasing of concentration too. The fiber uniformity was<br />

increased with increasing of concentration.<br />

In summary we calculated the throughput of nano web<br />

in g/min/m is shown in figure 2.<br />

(a)<br />

(b)<br />

Figure 3. (a) PVB nanofiber with 9%wt of PVB polymer, (b)<br />

PVB nanofiber with 10%wt of PVB polymer<br />

This work was partially supported by Technical<br />

University of Liberec. We thank to all technicians in TUL.<br />

*Corresponding author: HTfyener@ksu.edu.trT<br />

[1] An Introduction to Electrospinning and Nanofibers Seeram<br />

Ramakrishna, Kazutoshi Fujihara, Wee-Eong Teo.Teik-Cheng<br />

Lim & Zuwei Ma National University of Singapore<br />

[2] O. Jirsak, F. Sanetrnik, D. Lukas, V. Kotek, L. Martinova,and<br />

J. Chaloupek, Patent WO 2005024101 (2005).<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 772