Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

P<br />

461–464.<br />

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

The Effect of TiCN Coatings on Frictional Properties of Orthodontic Archwires<br />

1<br />

1<br />

1<br />

1<br />

1<br />

Uengül DanmanUP P*, Soner SavaP P, Gülfem IkP P, Tancan UysalP Pand Ahmet YacP<br />

1<br />

PErciyes University, Kayseri-Turkey<br />

Abstract-One of the main problems in the orthodontic treatment is the frictional forces on the archwires. The geometry of an archwire and the<br />

coatings applied on archwires affect these forces. In this study, the archwires were coated with TiCN by using dc reactive magnetron sputtering<br />

method. It was found that the coefficient of frictions of the TiCN coated archwires were much lower than those of uncoated archwires.<br />

Hard ceramic coatings deposited by PVD (Physical Vapour<br />

Deposition) techniques have been widely used in different<br />

industries because of their excellent coating properties: high<br />

hardness, good wear, corrosion and oxidation resistance,<br />

chemical resistance and good adhesion to the substrate. Today,<br />

in the field of biomedical applications - such as surgical tools,<br />

implants, lenses, stents, and materials used in dentistry - Ti,<br />

TiN, ZrN, TiAlN, DLC, etc. are successfully used as single or<br />

multilayered or nanolayered coatings. These coatings also<br />

have good bio-conformity with the human body [1-6].<br />

The objective of this study was to shorten the active<br />

treatment time in the orthodontic treatment by reducing the<br />

static and dynamic friction between the brackets and<br />

archwires. It was clearly seen that the friction was affected not<br />

only archwire geometry and materials but also surface quality<br />

of archwires. Today, esthetic brackets are preferred to the<br />

traditional ones and, therefore, frictional forces on archwires<br />

are increased. These forces affect the movement of the<br />

archwire and extend the duration of the treatment. Therefore,<br />

low frictional coatings are very important for orthodontic<br />

archwires.<br />

In this study, the archwires were coated with TiCN by using<br />

dc reactive magnetron sputtering method with the optimum<br />

deposition parameters. The dynamic and static frictional<br />

forces and surface roughnesses of the TiCN-coated and<br />

uncoated archwires (NiTi, BTi (TMA) and stainless steel<br />

archwires, 0.0<strong>17</strong>"x0.025" and Ø0.016" in dimensions) were<br />

measured. Then, the friction coefficients of TiCN coated and<br />

uncoated archwires were determined by using CSEM tester<br />

under the frictional forces (10 mm/min progress speed and 10<br />

N load were used as test parameters) and the results were<br />

discussed comparatively.<br />

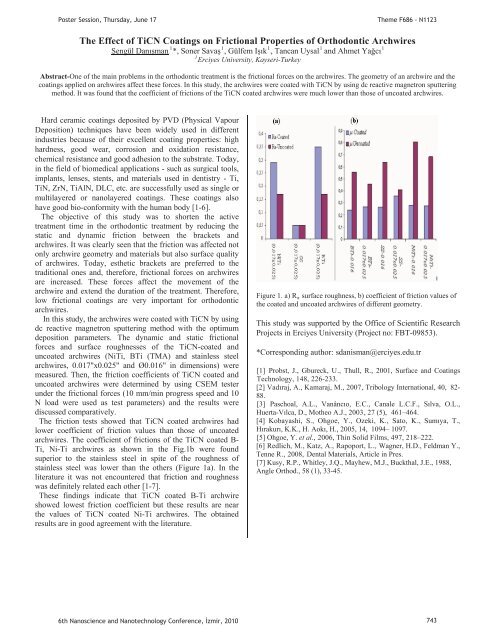

The friction tests showed that TiCN coated archwires had<br />

lower coefficient of friction values than those of uncoated<br />

archwires. The coefficient of frictions of the TiCN coated B-<br />

Ti, Ni-Ti archwires as shown in the Fig.1b were found<br />

superior to the stainless steel in spite of the roughness of<br />

stainless steel was lower than the others (Figure 1a). In the<br />

literature it was not encountered that friction and roughness<br />

was definitely related each other [1-7].<br />

These findings indicate that TiCN coated B-Ti archwire<br />

showed lowest friction coefficient but these results are near<br />

the values of TiCN coated Ni-Ti archwires. The obtained<br />

results are in good agreement with the literature.<br />

Figure 1. a) RRaR surface roughness, b) coefficient of friction values of<br />

the coated and uncoated archwires of different geometry.<br />

This study was supported by the Office of Scientific Research<br />

Projects in Erciyes University (Project no: FBT-09853).<br />

*Corresponding author: sdanisman@erciyes.edu.tr<br />

T[1] TProbst, J., Gbureck, UT., Thull, R., 2001, Surface and Coatings<br />

TTechnology, 148, 226-233.<br />

[2] Vadraj, A., Kamaraj, M., 2007T, Tribology International, 40, 82-<br />

88.<br />

T[3] TPaschoal, A.L., Vanânco, E.C., Canale L.C.F., Slva, O.L.,<br />

Huerta-Vlca, D., Motheo A.J., 2003T, 27 (5), T<br />

[4] Kobayashi, S., Ohgoe, Y., Ozeki, K., Sato, KT., Sumya, T.,<br />

Hrakur, K.K., H. Aok, H., 2005, 14, 1094– 1097.<br />

T[5] Ohgoe, Y. et al., T2006, Thin Solid Films, 497, 218–222.<br />

[6] Redlich, M., Katz, A., Rapoport, L., T Wagner, H.D., Feldman Y.,<br />

Tenne RT., T2008,T TDental Materials, Article in Pres.<br />

T[7] Kusy, R.P., Whitley, J.Q., Mayhew, M.J., Buckthal, J.E., 1988,<br />

Angle Orthod., 58 (1), 33-45.<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 743