Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Third Day Poster Session, 17 June 2010 - NanoTR-VI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Poster</strong> <strong>Session</strong>, Thursday, <strong>June</strong> <strong>17</strong><br />

Theme F686 - N1123<br />

A New Method: Thickness Determination of Thin Films by Energy Dispersive X-ray<br />

Spectroscopy<br />

Sedat Canli 1,2* , Mustafa Kulakci 3 , Urcan Guler 3 , Rasit Turan 2,3<br />

1 Micro and Nanotechnology Department, Middle East Technical University, 06531 Ankara, Turkey<br />

2 Central Laboratory, Middle East Technical University, 06531 Ankara, Turkey<br />

3 Department of Physics, Middle East Technical University, 06531 Ankara, Turkey<br />

Abstract- EDS is a tool for quantitative and qualitative analysis of the materials. In electron microscopy, the energy of the<br />

electrons determines the depth of the region where the x-rays come from. By varying the energy of the electrons, the depth of<br />

the region where x-rays come from can be changed. Different quantitative ratios of the elements for different electron<br />

energies can be obtained using a thin film. The thickness of a specific film on a specific substrate corresponds to a unique<br />

energy-ratio diagram. In this study, it is shown that thickness of a thin film can be obtained by an appropriate analysis of the<br />

energy-ratio diagram of the EDS data obtained from the film.<br />

Scanning Electron Microscopes (SEM) and Energy<br />

Dispersive X-ray Spectroscopy (EDS) methods are<br />

being widely used in materials and nanotechnology<br />

researches. Thin films are very important for several<br />

industries, such as electronic semiconductor industry,<br />

optical coating industry or photovoltaic cells. In the<br />

current work, EDS was investigated as a potential tool<br />

to be used as a relatively easy methodology for<br />

measuring the thickness of thin films.<br />

Silicon, the main material of semiconductor<br />

technology was used as the substrate in this study.<br />

Gold, germanium and aluminum were coated on<br />

substrates by thermal evaporation method and SiO 2 was<br />

grown by the wet oxidation method. Corroborative<br />

thickness measurements were obtained by profilometer<br />

and ellipsometry.<br />

It is known that the electron beam generated by an<br />

SEM hits perpendicularly onto the surface of the films<br />

and the interaction volume changes with the applied<br />

electron energy. In the present study, energy values in<br />

the range of 3keV to 30keV with steps of 1keV were<br />

used.<br />

Figure 1: Monte Carlo electron trajectory simulations of the<br />

interaction volume in Fe at (a) 10keV. (b) 20keV. (c) 30keV [1].<br />

At atomic scale, focused electrons hitting the sample<br />

excite inner electrons of the atoms. During the<br />

relaxation of the atoms, each atom radiates<br />

characteristic x-rays from K α , K β , L α , etc shells [2]. The<br />

detector collects and counts x-rays coming from the<br />

sample and constructs the spectrum. The EDS system<br />

normalizes and corrects the data using ZAF<br />

coefficients, and finally gives ratios of the elements.<br />

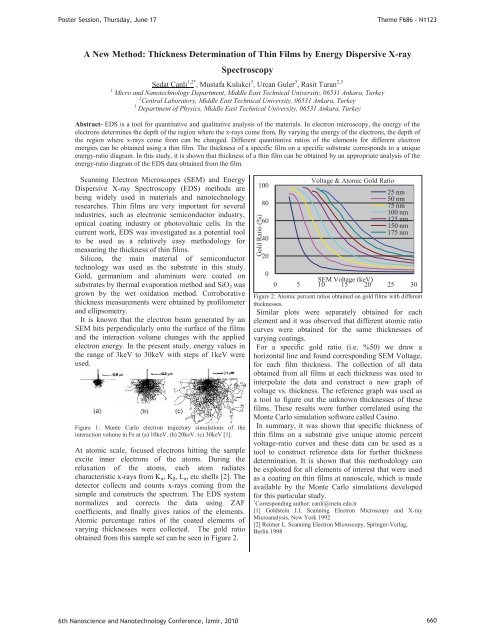

Atomic percentage ratios of the coated elements of<br />

varying thicknesses were collected. The gold ratio<br />

obtained from this sample set can be seen in Figure 2.<br />

Gold Ratio (%)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Voltage & Atomic Gold Ratio<br />

25 nm<br />

50 nm<br />

75 nm<br />

100 nm<br />

125 nm<br />

150 nm<br />

<strong>17</strong>5 nm<br />

SEM Voltage (keV)<br />

0 5 10 15 20 25 30<br />

Figure 2: Atomic percent ratios obtained on gold films with different<br />

thicknesses.<br />

Similar plots were separately obtained for each<br />

element and it was observed that different atomic ratio<br />

curves were obtained for the same thicknesses of<br />

varying coatings.<br />

For a specific gold ratio (i.e. %50) we draw a<br />

horizontal line and found corresponding SEM Voltage,<br />

for each film thickness. The collection of all data<br />

obtained from all films at each thickness was used to<br />

interpolate the data and construct a new graph of<br />

voltage vs. thickness. The reference graph was used as<br />

a tool to figure out the unknown thicknesses of these<br />

films. These results were further correlated using the<br />

Monte Carlo simulation software called Casino.<br />

In summary, it was shown that specific thickness of<br />

thin films on a substrate give unique atomic percent<br />

voltage-ratio curves and these data can be used as a<br />

tool to construct reference data for further thickness<br />

determination. It is shown that this methodology can<br />

be exploited for all elements of interest that were used<br />

as a coating on thin films at nanoscale, which is made<br />

available by the Monte Carlo simulations developed<br />

for this particular study.<br />

* Corresponding author: canli@metu.edu.tr<br />

[1] Goldstein J.I. Scanning Electron Microscopy and X-ray<br />

Microanalysis, New York 1992<br />

[2] Reimer L. Scanning Electron Microscopy, Springer-Verlag,<br />

Berlin 1998<br />

6th Nanoscience and Nanotechnology Conference, zmir, <strong>2010</strong> 660