Photonic crystals in biology

Photonic crystals in biology

Photonic crystals in biology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Phos ph<strong>in</strong>e oxi de bas ed polyurethane / silica nanocompos ites via nonisocyanate route<br />

1,2 1 , Nilhan Kayaman-Apohan 1 *,<br />

<br />

3 , Atilla Güngör 1<br />

1 Marmara University, Department of Chemistry, 34722 Göztepe-Istanbul/ Turkey<br />

2 Trakya University, Department of Chemistry, Edirne/ Turkey<br />

3 -Istanbul/ Turkey<br />

Abstract-The ma<strong>in</strong> objective of this work is to develop environmentally friendly and flame-resistant polyurethane-silica nanocomposite coat<strong>in</strong>gs.<br />

For t his purpose, a novel carbonate modified bis (4-glycidyloxy phenyl) phenyl phosph<strong>in</strong>e oxide (CBGPPO) was synthesized to prepare<br />

nanocomposites via nonisocyanate route. The cupp<strong>in</strong>g, impact and gloss measurements were performed on alum<strong>in</strong>um panels, and the tensile test,<br />

gel content, thermal and morphological analyses were conducted on the free films.<br />

Applications of polyurethane (PU) materials have<br />

significantly <strong>in</strong>creased <strong>in</strong> comparison with some other<br />

thermosett<strong>in</strong>g polymer materials. Conventional polyurethanes<br />

have good mechanical properties but they are porous and<br />

possess poor hydrolytic stability and <strong>in</strong>sufficient permeability.<br />

The <strong>in</strong>volvement of toxic components, such as isocyanates, <strong>in</strong><br />

their fabrication process makes the production extremely toxic<br />

and dangerous. In this sense, a pioneer<strong>in</strong>g method, which<br />

depends on the reaction between cyclocarbonate oligomers<br />

and primary am<strong>in</strong>e oligomers, has been developed for<br />

environmental-friendly PU manufactur<strong>in</strong>g. Cyclocarbonates<br />

that can be synthesized from correspond<strong>in</strong>g epoxy precursors<br />

are attract<strong>in</strong>g research <strong>in</strong>terest due to their potential use <strong>in</strong> the<br />

preparation of green, porous free and moisture <strong>in</strong>sensitive<br />

polyurethanes.[1,2]<br />

A feasible approach for improv<strong>in</strong>g flame retardation of<br />

polyurethanes <strong>in</strong>volves the synthesis of phosphorus conta<strong>in</strong><strong>in</strong>g<br />

polyurethanes. S<strong>in</strong>ce traditional halogen-based flameretardants<br />

have disadvantages such as the potentiality of<br />

corrod<strong>in</strong>g metal components and toxic corrosive fumes of<br />

hydrogen halide dur<strong>in</strong>g the combustion, halogen-free flameretardants<br />

for polymers have attracted more attention from<br />

scientists <strong>in</strong> recent years.[3,4]<br />

Therefore, eight different formulations of nanocomposites<br />

were prepared to <strong>in</strong>vestigate the effects of silica and phosph<strong>in</strong>e<br />

oxide based cyclocarbonate oligomer on the coat<strong>in</strong>g<br />

properties.<br />

Table 1. Formulation ratios of naocomposites<br />

KOD<br />

SOL-<br />

JEL<br />

%<br />

CPPG<br />

(g)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

CBGPPO<br />

(g)<br />

HMDA<br />

(g)<br />

CPPG(100)-<br />

CBGPPO(0)-Si(0) 0 8 - 1.534<br />

CPPG(75)-<br />

CBGPPO(25)-Si(0) 0 6 2 1.663<br />

CPPG(50)-<br />

CBGPPO(50)-Si(0) 0 4 4 1.86<br />

CPPG(100)-<br />

CBGPPO(0)-Si(20) 20 8 - 1.63<br />

CPPG(75)-<br />

CBGPPO(25)-Si(20) 20 6 2 1.76<br />

CPPG(50)-<br />

CBGPPO(50)-Si(20) 20 4 4 1.96<br />

CPPG(75)-<br />

CBGPPO(25)-Si(10) 10 6 2 1.71<br />

CPPG(75)-<br />

CBGPPO(25)-Si(5) 5 6 2 1.687<br />

impact, cupp<strong>in</strong>g, gel content and stress-stra<strong>in</strong> tests. Thermal<br />

behaviors and morphologic properties of the coat<strong>in</strong>gs were<br />

also <strong>in</strong>vestigated. Incorporation of silica and CBGPPO <strong>in</strong>to<br />

formulations <strong>in</strong>creased modulus and hardness of the coat<strong>in</strong>gs.<br />

It was also observed that, the thermal stability of hybrid<br />

coat<strong>in</strong>gs enhanced with the addition of silica and CBGPPO.<br />

O<br />

O<br />

CH 2<br />

-CH-CH 2 O P O CH 2<br />

-CH-CH 2<br />

O<br />

CH 2<br />

-CH-CH 2 O P O CH 2<br />

-CH-CH 2<br />

O<br />

O<br />

O<br />

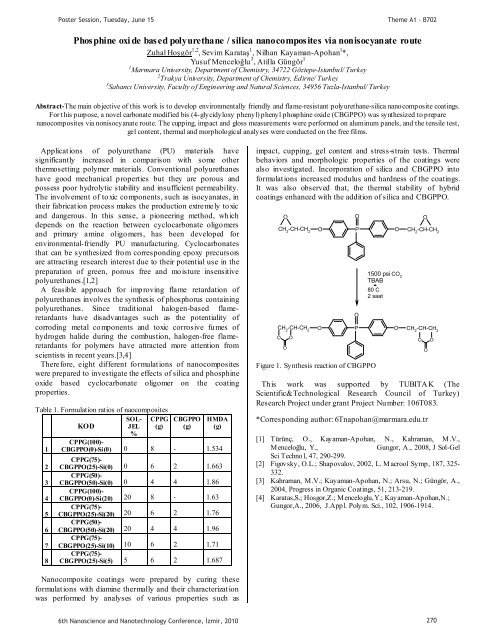

Figure 1. Synthesis reaction of CBGPPO<br />

1500 psi CO 2<br />

TBAB<br />

80 C<br />

2 saat<br />

This work was supported by TUBITAK (The<br />

Scientific&Technological Research Council of Turkey)<br />

Research Project under grant Project Number: 106T083.<br />

*Correspond<strong>in</strong>g author: 6Tnapohan@marmara.edu.tr<br />

[1] Türünç, O., Kayaman-Apohan, N., Kahraman, M.V.,<br />

Men Gungor, A., 2008, J Sol-Gel<br />

Sci Techno l, 47, 290-299.<br />

[2] Figovsky, O.L.; Shapovalov, 2002, L. M acrool Symp, 187, 325-<br />

332.<br />

[3] Kahraman, M.V.; Kayaman-Apohan, N.; Arsu, N.; Güngör, A.,<br />

2004, Progress <strong>in</strong> Organic Coat<strong>in</strong>gs, 51, 213-219.<br />

[4] Karatas,S.; Hosgor,Z.; Menceloglu,Y.; Kayaman-Apohan,N.;<br />

Gungor,A., 2006, J.Appl. Polym. Sci., 102, 1906-1914.<br />

O<br />

O<br />

O<br />

O<br />

Nanocomposite coat<strong>in</strong>gs were prepared by cur<strong>in</strong>g these<br />

formulations with diam<strong>in</strong>e thermally and their characterization<br />

was performed by analyses of various properties such as<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 270