- Page 1 and 2:

GOVERNMENT OF MADHYA PRADESH, URBAN

- Page 3 and 4:

SECTION 100

- Page 5 and 6:

101 INTRODUCTION These specificatio

- Page 7 and 8:

13.2 74 *11.2 *63 9.50 53 *8.00 *45

- Page 9 and 10:

107 CONTRACT DRAWINGS 107.1 The Con

- Page 11 and 12:

110.3 No clearance or alterations t

- Page 13 and 14:

Any vehicle with open load-carrying

- Page 15 and 16:

warning lights of similar type shal

- Page 17 and 18:

Location of the scales shall be as

- Page 19 and 20:

c) Sequence of construction and det

- Page 21 and 22:

ecording shall be done in the prese

- Page 23 and 24:

IRC : 47-1972 IRC : 48-1972 Tentati

- Page 25 and 26:

Number Designation IS:1216-1978 IS:

- Page 27 and 28:

Number Designation IS:12269-1987 IS

- Page 29 and 30:

Number Designation BS:7542 CRR I &

- Page 31 and 32:

CONTENT Clause No Description 201 S

- Page 33 and 34:

(v) All products of clearing and gr

- Page 35 and 36:

202.6. Measurements for Payment The

- Page 37 and 38:

CONTENT Clause No Description 301 E

- Page 39 and 40:

301.3 Construction Operations 301.3

- Page 41 and 42:

301.6 Preparation of Cut Formation

- Page 43 and 44:

(13) At a time, not more than 10 ch

- Page 45 and 46:

All overburden soil and weathered r

- Page 47 and 48:

If it is determined beforehand that

- Page 49 and 50:

11. Excavation in marshes shall beg

- Page 51 and 52:

Table 300-2 Compaction Requirements

- Page 53 and 54:

maintained at such a crossfall (not

- Page 55 and 56:

(c) Only the materials satisfying t

- Page 57 and 58:

4 Where the available embankment ma

- Page 59 and 60:

of drainage. 309.2 Surface Drains S

- Page 61 and 62:

Damage to the fabric resulting from

- Page 63 and 64:

CONTENT Clause No 401 GRANULAR SUB-

- Page 65 and 66:

TABLE 400-1. GRADING FOR CLOSE -GRA

- Page 67 and 68:

(iii) Compaction: Density shall be

- Page 69 and 70:

402.3.6. Addition of lime: Lime may

- Page 71 and 72:

TABLE 400 -6. PHYSICAL REQUIREMENTS

- Page 73 and 74:

The consolidated details of quantit

- Page 75 and 76:

(4) Rolling shall be discontinued w

- Page 77 and 78:

(ii) Furnishing all materials to be

- Page 79 and 80:

(4) Optimum moisture for mixing sha

- Page 81 and 82:

406.8 Measurements for Payment Wet

- Page 83 and 84:

iv) For kerb in running meters v) F

- Page 85 and 86:

409.3.4 Precast cement concrete blo

- Page 87 and 88:

The surface finish of construction

- Page 89 and 90:

CONTENT Clause No Description 501 G

- Page 91 and 92:

(k) Use of Premix seal coat:- It is

- Page 93 and 94:

Number 0 and 1 are of very low cons

- Page 95 and 96:

area beyond it, shall be laid by ha

- Page 97 and 98:

501.8. Preparation of Surface 501.8

- Page 99 and 100:

Normally, the maximum layer thickne

- Page 101 and 102:

5. 6. Bituminous penetration macada

- Page 103 and 104:

Control of temperature of binder in

- Page 105 and 106:

501.8.7.5 Tack coat: This is to be

- Page 107 and 108:

6. Emergency Response 6.1. The Cont

- Page 109 and 110:

carpet to ensure a proper bond betw

- Page 111 and 112:

504.2.2. Coarse aggregates: (i)The

- Page 113 and 114:

504.8. Rate The cont react unit rat

- Page 115 and 116:

505.7. Measurement for Payment Pene

- Page 117 and 118:

The contract unit rate for built-up

- Page 119 and 120:

507.3. Mixture Design 507.3.1. Requ

- Page 121 and 122:

507.4. Construction Operations 507.

- Page 123 and 124:

1. IS: 2386 Part 1 2. IS: 2386 Part

- Page 125 and 126:

508.8. Measurement for Payment The

- Page 127 and 128:

Notes: 1. The combined aggregate gr

- Page 129 and 130:

ase, followed by a cover of stone c

- Page 131 and 132:

The equipment and general procedure

- Page 133 and 134:

Aggregates (a) Nominal Stone size 1

- Page 135 and 136:

(A) Premix Carpet (a) Coarse aggreg

- Page 137 and 138:

511.2.6. Surface finish and quality

- Page 139 and 140:

(i)The stone chips shall consist of

- Page 141 and 142:

S. No. Nominal size of aggregate De

- Page 143 and 144:

* In cold climatic regions (tempera

- Page 145 and 146:

(vi)During cooking and mixing, care

- Page 147 and 148:

(i)It is usual to use ordinary Port

- Page 149 and 150:

(iii)The Contractor shall monitor t

- Page 151 and 152:

519.2.1.3. Aggregate grading and bi

- Page 153 and 154:

evaporation of water and/or solvent

- Page 155 and 156:

519.3.1.3 Aggregate grading and bin

- Page 157 and 158:

519.3.6. Measurement for payment: R

- Page 159 and 160:

Loss in Weight, %., Maximum Increas

- Page 161 and 162: 522.2. Materials 522.2.1. Binder: B

- Page 164 and 165: 600 Concrete Pavements

- Page 166 and 167: 601. DRY LEAN CEMENT CONCRETE SUB-B

- Page 168 and 169: 601.4. Subgrade The subgrade shall

- Page 170 and 171: 601.5.7. Curing: As soon as the lea

- Page 172 and 173: 602.2. Materials 602.2.1. Source of

- Page 174 and 175: 602.3.2. Cement content: The cement

- Page 176 and 177: 602.6.2.2. Contraction joints: Cont

- Page 178 and 179: 602.6.6. Tie bars 602.6.6.1. Tie ba

- Page 180 and 181: 602.9.3.2. Batching plant and equip

- Page 182 and 183: 602.9.5.2. The concrete shall be di

- Page 184 and 185: mechanical sprayer shall incorporat

- Page 186 and 187: after concrete has set to expose do

- Page 188 and 189: joints is completed including the c

- Page 190 and 191: 603.2.3.4. The coarse and fine aggr

- Page 192: 603.9. Tolerances for Surface Regul

- Page 195 and 196: 701 GEOSYNTHETICS IN ROAD AND BRIDG

- Page 197 and 198: Table 700-2 Geotextile Requirements

- Page 199 and 200: strong acid/bases, flames including

- Page 201 and 202: 702.4 Measurement for Payment The g

- Page 203 and 204: dimensional stability relative to e

- Page 205 and 206: 706 GEOSYNTHETICS FOR HIGHWAY PAVEM

- Page 207 and 208: 707.2.3 Tack coat: The tack coat us

- Page 209 and 210: 708.3.2 Construction and installati

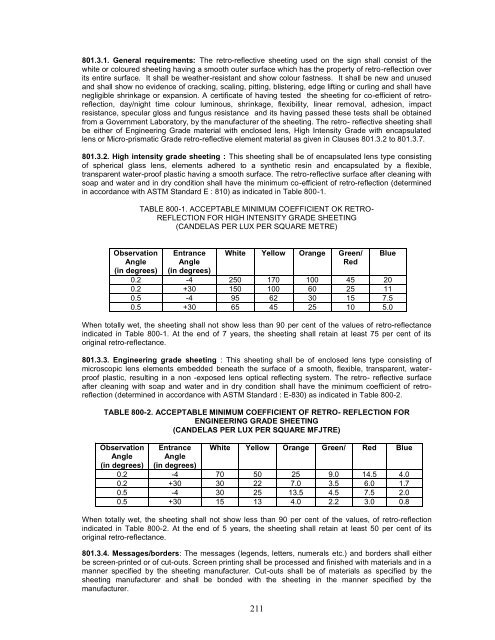

- Page 211: CONTENT Clause No Description 801 T

- Page 215 and 216: lack free adhesive activated by hea

- Page 217 and 218: (iii) (iv) (v) (vi) (vii) (viii) (i

- Page 219 and 220: 802.1.1. Overhead signs may be used

- Page 221 and 222: 802.7.6. Before erecting support st

- Page 223 and 224: (c) Skid resistance : not less than

- Page 225 and 226: (b) The marking shall not lift from

- Page 227 and 228: The work covers supplying and fixin

- Page 229 and 230: 809.3.1. The location of crash barr

- Page 231: 810.7.3. No measurement for payment

- Page 234 and 235: 901. GENERAL 901.1. All materials t

- Page 236 and 237: 902.3. Surface Levels The levels of

- Page 238 and 239: eplacement of a bituminous layer is

- Page 240 and 241: per 5 tones 3. Water Bound Macadam

- Page 243 and 244: CONTENT Clause No Description 1001

- Page 245 and 246: ecommended threshold values as per

- Page 247 and 248: S 415 IS:17B6 High Yield 415 200 St

- Page 249 and 250: and testing of concrete. The contra

- Page 251 and 252: prevented. The use of correctly for

- Page 254 and 255: CONTENT Clause No Description 1101

- Page 256 and 257: 1105. TEST PILES 1105.1. Test piles

- Page 258 and 259: The concrete shall be properly grad

- Page 260 and 261: During driving the top of pile shal

- Page 262 and 263:

concrete in the installed pile and

- Page 264:

the head to the butt of the shoe or

- Page 267 and 268:

1201. DESCRIPTION This work consist

- Page 269 and 270:

1205. WELL CURB 1205.1. The well cu

- Page 271 and 272:

Separate high pressure connection f

- Page 273 and 274:

Care shall be taken to keep all par

- Page 275 and 276:

The well shall be uniformly seated

- Page 277 and 278:

d) The Contract unit rates for sand

- Page 279 and 280:

CONTENT Clause No 1301 DESCRIPTION

- Page 281 and 282:

Such soaked bricks shall be stacked

- Page 283 and 284:

The surfaces can be finished by "jo

- Page 285 and 286:

In case of plaster finish, the mini

- Page 287 and 288:

CONTENT Clause No Description 1401

- Page 289 and 290:

e fluid mixed thoroughly and then p

- Page 291 and 292:

1405.3.5. Quoin stone : Quoin stone

- Page 293 and 294:

1405.9. Wee Holes Weep holes shall

- Page 295 and 296:

CONTENT Clause No Description 1501

- Page 297 and 298:

1504.6. Shuttering for walls, slopi

- Page 299 and 300:

When formwork is dismantled, its in

- Page 301 and 302:

CONTENT Clause No Description 1601

- Page 303 and 304:

(i) In case of beam and slab constr

- Page 305 and 306:

(iii)The fabrication, furnishing an

- Page 307 and 308:

CONTENT Clause No Description 1701

- Page 309 and 310:

TABLE 1700-3. FOR BRIDGES OTHER THA

- Page 311 and 312:

(iii)The initial trial mixes shall

- Page 313 and 314:

Unless specified otherwise, equipme

- Page 315 and 316:

All under water concreting shall be

- Page 317 and 318:

disappears. The second application

- Page 319 and 320:

(iv) After the passage of the above

- Page 321 and 322:

CONTENT Clause No Description 1801

- Page 323 and 324:

1802.2.3. In severe environment, ca

- Page 325 and 326:

strength of steel to concrete. Grou

- Page 327 and 328:

) If the calculated elongation has

- Page 329 and 330:

1809.5. Protection of Ends The expo

- Page 331 and 332:

1900 Structural Steel

- Page 333 and 334:

1901. DESCRIPTION This work shall i

- Page 335 and 336:

All work shall be in accordance wit

- Page 337 and 338:

1904.3.2. Block drilling : Where th

- Page 339 and 340:

Taper washers with correct angle of

- Page 341 and 342:

Welding shall not be done when the

- Page 343 and 344:

column. This dimension shall be mea

- Page 345 and 346:

IS:7969 dealing with handling of ma

- Page 347 and 348:

(i) (ii) (iii) iv) Visual Inspectio

- Page 349 and 350:

(ii) Chemical Resistant Paints The

- Page 351 and 352:

Two coats of aluminum paint conform

- Page 353:

Weight of structural secti ons shal

- Page 356 and 357:

2001. DESCRIPTION This work shall c

- Page 358 and 359:

Tolerances on height of any compone

- Page 360 and 361:

A bottom plate with concave surface

- Page 362 and 363:

3.1 Max change in Hardness IRHD +15

- Page 364 and 365:

The size and composition of accepta

- Page 366 and 367:

1. Acceptance testing by an indepen

- Page 368 and 369:

ii) Template of 6 mm M.S. plate and

- Page 370 and 371:

ix) Pot bearings including all pans

- Page 372 and 373:

ii) Overall height : -0 to +3 mm ii

- Page 374 and 375:

2008. TESTS AND STANDARDS OF ACCEPT

- Page 376 and 377:

CONTENT Clause No Description 2101

- Page 378 and 379:

Formwork and concrete shall conform

- Page 380 and 381:

CONTENT Clause No Description 2201

- Page 382 and 383:

The surface on which elastomeric be

- Page 384 and 385:

CONTENT Clause No Description 2301

- Page 386 and 387:

The surface finish of the deck slab

- Page 388 and 389:

2400 Surface and Sub-surface Geotec

- Page 390 and 391:

2401. GENERAL 2401.1. The objective

- Page 392 and 393:

2403.5. Logging of bore-holes by ra

- Page 394 and 395:

For preliminary and detailed sub-su

- Page 396 and 397:

2408.4. Rock Samples 2408.4.1. Dist

- Page 398 and 399:

1. (a) During construction or immed

- Page 400 and 401:

2500 River Training Work and Protec

- Page 402 and 403:

2501 DESCRIPTION River training and

- Page 404 and 405:

Wherever possible, crates shall be

- Page 406 and 407:

2505. RUBBLE STONE/CEMENT CONCRETE

- Page 408 and 409:

2600 Expansion Joints

- Page 410 and 411:

2601. DESCRIPTION This work shall c

- Page 412 and 413:

2603.4. Performance Requirement wit

- Page 414 and 415:

2606. ELASTOMERIC SLAB SEAL EXPANSI

- Page 416 and 417:

iii) While removing the spacer bar

- Page 418 and 419:

ix) All excess sealant shall be rem

- Page 420 and 421:

TABLE 2600-1. STRIP SEAL ELEMENT SP

- Page 422 and 423:

iii) In view of the importance of t

- Page 424 and 425:

2700 Wearing Coat and Appurtenances

- Page 426 and 427:

2701. DESCRIPTION This work shall i

- Page 428 and 429:

deck structure. In case of viaducts

- Page 430 and 431:

2800 Repair of Structures

- Page 432 and 433:

2801. DESCRIPTION Repair of structu

- Page 434 and 435:

ecommendations. When mined, all adh

- Page 436 and 437:

Bond Strength : 12 MPa Tensile Stre

- Page 438 and 439:

Grouting shall normally be performe

- Page 440 and 441:

2807.11. Sufficient clearance shall

- Page 442 and 443:

The behaviour of the girder shall b

- Page 444 and 445:

CONTENT Clause No Description 2901

- Page 446 and 447:

suffer any undue structural strain,

- Page 448 and 449:

3000 Maintenance of Road

- Page 450 and 451:

3001. GENERAL The Specifications sh

- Page 452 and 453:

3004.1.5. Measurements for payment: