- Page 1 and 2:

Post Flight Analysis — Final Repo

- Page 3 and 4:

Signatures & ApprovalsPrepared byPu

- Page 5 and 6:

Table of ContentsPreface . . . . .

- Page 8 and 9:

6.8 Sources and References . . . .

- Page 10 and 11:

11 Telescope Readout Subsystem (TRE

- Page 12 and 13:

14 Data Collection, Processing & An

- Page 14 and 15:

xiv March 2007 Table of Contents

- Page 16 and 17:

Figure 3-4. The GP-B dewar—one of

- Page 18 and 19:

Figure 8-5. The Seasons of GP-B . .

- Page 20 and 21:

Figure 11-20. Pointing angle differ

- Page 22 and 23:

Figure 14-9. In the Anomaly Room, t

- Page 24 and 25:

xxiv March 2007

- Page 26 and 27:

Table 13-3. GP-B payload magnetomet

- Page 28 and 29:

xxviiiMarch 2007

- Page 30 and 31:

2 March 2007 Chapter 1 — Executiv

- Page 32 and 33:

facility, it was necessary to recas

- Page 34 and 35:

spacetime around with them as they

- Page 36 and 37:

After years of work and the inventi

- Page 38 and 39:

axis of a gyroscope rotor changes i

- Page 40 and 41:

Figure 1-8. Clockwise, from top lef

- Page 42 and 43:

“management experiment.” This w

- Page 44 and 45:

Attitude-Control Gyroscopes. Two pa

- Page 46 and 47:

Any significant deviation from “g

- Page 48 and 49:

established, ranging from Level 1 (

- Page 50 and 51:

1.14 The Broader Legacy of GP-BAt l

- Page 52 and 53:

24 March 2007 Chapter 2 — Overvie

- Page 54 and 55:

Figure 2-1. GP-B Historical Time Li

- Page 56 and 57:

Applied Physics Laboratory, of the

- Page 58 and 59:

William Fairbank once remarked: “

- Page 60 and 61:

In Einstein’s view, space and tim

- Page 62 and 63:

y a mere 1.1 inches. You can see th

- Page 64 and 65:

Figure 2-10. Schematic diagram of t

- Page 66 and 67:

Figure 2-12. Final assembly of the

- Page 68 and 69:

Sun Shield. The sun shield is a lon

- Page 70 and 71:

2.1.8 The Broader Legacy of GP-BWhe

- Page 72 and 73:

2.3 Spacecraft SeparationThe Solar

- Page 74 and 75:

Flight Anomalies.) Furthermore, a d

- Page 76 and 77:

Table 2-2. Weekly summary of IOC ac

- Page 78 and 79:

2.4.3.2 Guide Star AcquisitionAbout

- Page 80 and 81:

A second mass trim operation had be

- Page 82 and 83:

On Friday, 2 July 2004, the spin ra

- Page 84 and 85:

Low temperature bakeout was first p

- Page 86 and 87:

2.5.1.3 Lockheed Martin Team Phase-

- Page 88 and 89:

Monthly Highlights of the GP-B Scie

- Page 90 and 91:

2.6.1 Overview of the Calibration P

- Page 92 and 93:

Weekly Highlights of the GP-B Final

- Page 94 and 95:

66 March 2007 Chapter 3 — Accompl

- Page 96 and 97:

It was in this pristine, near-zero

- Page 98 and 99:

Each quartz rotor is coated with a

- Page 100 and 101:

Figure 3-3. Functional diagram of a

- Page 102 and 103:

Based on data from the on-board tel

- Page 104 and 105:

Ideally, the telescope should have

- Page 106 and 107:

Figure 3-9. Schematic diagram of st

- Page 108 and 109:

used. The star trackers are essenti

- Page 110 and 111:

Result: By using the porous plug, w

- Page 112 and 113:

Solution: Create a tetrahedral lapp

- Page 114 and 115:

Constraint 2: The exhaust tube must

- Page 116 and 117:

Result: The on-orbit gyroscope spin

- Page 118 and 119:

spacecraft's subsystems for the dur

- Page 120 and 121:

Constraint 3: Keep the spacecraft p

- Page 122 and 123:

Technology Category Specific Implem

- Page 124 and 125:

96 March 2007 Chapter 4 — GP-B On

- Page 126 and 127:

Any significant deviation from “g

- Page 128 and 129: packages, one for each Ping load an

- Page 130 and 131: In addition to these software packa

- Page 132 and 133: Table 4-6. Features & benefits of W

- Page 134 and 135: This software added considerable ef

- Page 136 and 137: It is said that “an experiment is

- Page 138 and 139: Table 4-10. Significant Events/Sour

- Page 140 and 141: Figure 4-5. Pictorial depiction of

- Page 142 and 143: Figure 4-7. Eta-Average Error Assoc

- Page 144 and 145: 4.4.4.2 OD Using SLR DataFigure 4-9

- Page 146 and 147: 4.4.5 ConclusionsFigure 4-11. Compa

- Page 148 and 149: Overall, the storage issues did not

- Page 150 and 151: Table 4-11. ITF equipment listEQUIP

- Page 152 and 153: 124 March 2007 Chapter 5 — Managi

- Page 154 and 155: 5.2 Overview of GP-B Anomalies in O

- Page 156 and 157: Figure 5-1. Anomaly Review Team Org

- Page 158 and 159: 5.3.3.1 Anomaly Investigation and R

- Page 160 and 161: 5.3.5 Anomaly Identification and Re

- Page 162 and 163: 5.4.3 Risk Management ApproachThe r

- Page 164 and 165: Table 5-1. Summary of Open GP-B ris

- Page 166 and 167: 138 March 2007 Chapter 5 — Managi

- Page 168 and 169: 140 March 2007 Chapter 6 — The GP

- Page 170 and 171: 3. Payload Integration, Testing and

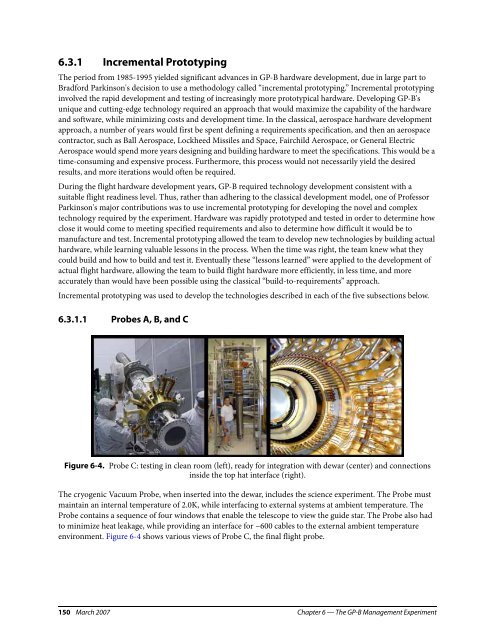

- Page 172 and 173: Figure 6-1. Clockwise from top left

- Page 174 and 175: MSFC conducted an in-house Phase A

- Page 176 and 177: It is important to note that from t

- Page 180 and 181: alignment, and act as an accelerome

- Page 182 and 183: Figure 6-9. The Lockheed Martin GP-

- Page 184 and 185: Furthermore, a fourth electronic sy

- Page 186 and 187: positive thermal connections betwee

- Page 188 and 189: astrophysics/cosmology. Many of the

- Page 190 and 191: Figure 6-10. MSFC Program Managers/

- Page 192 and 193: As described in Chapter 2, the flig

- Page 194 and 195: 6.7 Some Observations on the Manage

- Page 196 and 197: 168 March 2007 Chapter 6 — The GP

- Page 198 and 199: 170 March 2007 Chapter 7 — Attitu

- Page 200 and 201: 7.1.2 Vehicle ATC ModesThere are es

- Page 202 and 203: The output of the pressure transduc

- Page 204 and 205: Figure 7-3. Science Telescope Compo

- Page 206 and 207: Figure 7-5. Pitch and Yaw Pointing

- Page 208 and 209: Figure 7-7. Magnitude of the roll r

- Page 210 and 211: Changing the method by which the gy

- Page 212 and 213: 7.3.3 Drag-Free Control SystemFigur

- Page 214 and 215: 7.3.3.1 DFS - PerformanceThe GP-B d

- Page 216 and 217: Figure 7-15. Mass flow effects of a

- Page 218 and 219: 7.5.2 Successful recovery from mult

- Page 220 and 221: If the vehicle control system were

- Page 222 and 223: accomplish this, the ARPs are mount

- Page 224 and 225: 7.5.6.1 South Atlantic AnomalyProto

- Page 226 and 227: Figure 7-23. Effects on telescope p

- Page 228 and 229:

200 March 2007 Chapter 7 — Attitu

- Page 230 and 231:

202 March 2007 Chapter 8 — Other

- Page 232 and 233:

Figure 8-2. Block Diagram of CDH co

- Page 234 and 235:

8.1.1.4 WATCH DOG TIMERFigure 8-4.

- Page 236 and 237:

of eclipses each day (approximately

- Page 238 and 239:

Figure 8-8. GSS1 Temperature Trends

- Page 240 and 241:

Figure 8-10. Forward Dewar Vacuum S

- Page 242 and 243:

The Gravity Probe B spacecraft has

- Page 244 and 245:

Figure 8-13. Forward -X Thruster Te

- Page 246 and 247:

gaFigure 8-15. Aft -X Thruster Temp

- Page 248 and 249:

Because there are only two SQUID br

- Page 250 and 251:

Because the specifications for SRE

- Page 252 and 253:

8.3.2 Critical Mission RequirementT

- Page 254 and 255:

Figure 8-19 is a plot of the power

- Page 256 and 257:

Battery Performance Summary:Figure

- Page 258 and 259:

Figure 8-23. Solar Array Temperatur

- Page 260 and 261:

8.3.10 ConclusionThe electrical pow

- Page 262 and 263:

8.4.1 TDRSS OperationsFigure 8-28.

- Page 264 and 265:

Figure 8-30. Xpndr-A STDN (green),

- Page 266 and 267:

Figure 8-32. Plot of TDRS AGC vs Te

- Page 268 and 269:

The FSW also met its subsystem leve

- Page 270 and 271:

Appendix E, Flight Software Applica

- Page 272 and 273:

Table 8-4. SCRs Addressed in On-orb

- Page 274 and 275:

The software and macro changes resu

- Page 276 and 277:

Figure 8-38 below is an excerpt fro

- Page 278 and 279:

Figure 8-40. A-side CCCA Single Bit

- Page 280 and 281:

Figure 8-43. A-side CCCA Single Bit

- Page 282 and 283:

When single MBEs did not result in

- Page 284 and 285:

256 March 2007 Chapter 9 — Gyro S

- Page 286 and 287:

9.1 GSS Hardware DescriptionFigure

- Page 288 and 289:

significantly reduces and thus pres

- Page 290 and 291:

9.1.11 Clock synchronizationThe aft

- Page 292 and 293:

Figure 9-8. Block diagram of the LQ

- Page 294 and 295:

direction (transverse to the space

- Page 296 and 297:

9.2.2.2 Spin-up SuspensionDuring sp

- Page 298 and 299:

Figure 9-16. Predicted and measured

- Page 300 and 301:

Figure 9-18. The GSS passes rotor c

- Page 302 and 303:

Figure 9-20. Representative drag-fr

- Page 304 and 305:

Table 9-1. GSS Science Mission Mode

- Page 306 and 307:

Table 9-3. GSW application source l

- Page 308 and 309:

The Design and Testing of the Gravi

- Page 310 and 311:

282 March 2007 Chapter 10 — SQUID

- Page 312 and 313:

ate uncertainty). Although we have

- Page 314 and 315:

All of the GP-B electronics have be

- Page 316 and 317:

10.3 Pre-Launch Ground-Based TestsW

- Page 318 and 319:

Figure 10-6. AC Magnetic Shielding

- Page 320 and 321:

Figure 10-8. Temperature Error of S

- Page 322 and 323:

Figure 10-10. Quiescent SQUID Noise

- Page 324 and 325:

Analog control loops on the electro

- Page 326 and 327:

The science support applications ru

- Page 328 and 329:

Table 10-7. SSW application source

- Page 330 and 331:

Table 10-7. SSW application source

- Page 332 and 333:

Table 10-7. SSW application source

- Page 334 and 335:

Table 10-7. SSW application source

- Page 336 and 337:

308 March 2007 Chapter 11 — Teles

- Page 338 and 339:

Figure 11-1. Block diagram of TRE a

- Page 340 and 341:

Additionally, the warm electronics

- Page 342 and 343:

Figure 11-3. CLL switch states duri

- Page 344 and 345:

Table 11-3. Dates and UTC times whe

- Page 346 and 347:

Figure 11-7. Low Gamma Angle Data S

- Page 348 and 349:

s N+w i= sign+w i++−+−w i−w i

- Page 350 and 351:

expression, which otherwise on a po

- Page 352 and 353:

Figure 11-14. Y axis, B side RMS po

- Page 354 and 355:

Figure 11-17. X axis, B side curren

- Page 356 and 357:

Figure 11-20. Pointing angle differ

- Page 358 and 359:

Figure 11-24. Scaled summed current

- Page 360 and 361:

Figure 11-26 through Figure 11-29 s

- Page 362 and 363:

334 March 2007 Chapter 12 — Cryog

- Page 364 and 365:

12.2 Temperature / pressure control

- Page 366 and 367:

control the space vehicle without t

- Page 368 and 369:

Figure 12-3. Helium flow rate predi

- Page 370 and 371:

helium at 1.8 K. It does not appear

- Page 372 and 373:

Figure 12-6. Flow meter and ATC flo

- Page 374 and 375:

were generally within a day or so o

- Page 376 and 377:

shields) and subsequent instability

- Page 378 and 379:

350 March 2007 Chapter 12 — Cryog

- Page 380 and 381:

352 March 2007 Chapter 13 — Other

- Page 382 and 383:

Figure 13-2. ECU-operated heaters i

- Page 384 and 385:

13.1.3.1 Vatterfly Valve Operations

- Page 386 and 387:

13.1.3.7 Payload MagnetometersThe E

- Page 388 and 389:

Figure 13-11. ECU performance durin

- Page 390 and 391:

As we entered the second month of o

- Page 392 and 393:

During the last month of IOC, prepa

- Page 394 and 395:

Figure 13-19. ECU heater activity d

- Page 396 and 397:

Table 13-1. Proton monitor channel

- Page 398 and 399:

Figure 13-21. Proton Monitor data i

- Page 400 and 401:

In November, 2004 there was a large

- Page 402 and 403:

Figure 13-28 shows a correlation th

- Page 404 and 405:

13.3.1 About the MagnetometersFigur

- Page 406 and 407:

13.3.2 Other Applications for Paylo

- Page 408 and 409:

Figure 13-35. GPS Antennae Field of

- Page 410 and 411:

Figure 13-37. Master Antenna Switch

- Page 412 and 413:

Figure 13-39. Time difference betwe

- Page 414 and 415:

13.4.6 On-Orbit ResultsThe GPS comp

- Page 416 and 417:

and velocity values erroneously cal

- Page 418 and 419:

E. G. Lightsey, C. E. Cohen, B. W.

- Page 420 and 421:

Figure 13-45. A Bottom View of the

- Page 422 and 423:

Figure 13-48. The GMA configuration

- Page 424 and 425:

Table 13-10. Summary for Helium Gas

- Page 426 and 427:

398 March 2007 Chapter 14 — Data

- Page 428 and 429:

a relatively slow data rate, so we

- Page 430 and 431:

Figure 14-4. NASA ground stations a

- Page 432 and 433:

electronic components to recover fr

- Page 434 and 435:

By a process of elimination, the GP

- Page 436 and 437:

A special room in the GP-B Mission

- Page 438 and 439:

Starting on 3 December 1725, Bradle

- Page 440 and 441:

seemed that aberration of starlight

- Page 442 and 443:

14.1.6 Telescope Dither—Correlati

- Page 444 and 445:

14.1.6.3 The Telescope Dither Patte

- Page 446 and 447:

amplifications. Thus, in addition t

- Page 448 and 449:

14.2.2 Independent Data Analysis Te

- Page 450 and 451:

monthly time scales. Though only sh

- Page 452 and 453:

424 March 2007 Chapter 15 — Preli

- Page 454 and 455:

Figure 15-2. A diagram of the GP-B

- Page 456 and 457:

15.4 The Two Surprises and Their Im

- Page 458 and 459:

Near Zeroes.) The exception that we

- Page 460 and 461:

Figure 15-8. A slide from the GP-B

- Page 462 and 463:

Figure 15-9. A poster on the effect

- Page 464 and 465:

electrostatic patches, located at o

- Page 466 and 467:

Last summer (2006), Mac Keiser devi

- Page 468 and 469:

440 March 2007 Chapter 15 — Preli

- Page 470 and 471:

442 March 2007 Chapter 16 — Lesso

- Page 472 and 473:

16.1.1.3 Flight science downlink da

- Page 474 and 475:

Description of the GP-B experience:

- Page 476 and 477:

Lessons:1. Perform all tests with a

- Page 478 and 479:

Description of the GP-B experience:

- Page 480 and 481:

Figure 16-1. Six interacting transl

- Page 482 and 483:

16.1.3.2 Training and certification

- Page 484 and 485:

Description of the GP-B experience:

- Page 486 and 487:

Below is an edited summary of six a

- Page 488 and 489:

460 March 2007 Chapter 16 — Lesso

- Page 490 and 491:

462 March 2007 Appendix A — Gravi

- Page 492 and 493:

Apogee altitude659.1 km (409.6 mile

- Page 494 and 495:

466 March 2007 Chapter B — Spacec

- Page 496 and 497:

Gravity Probe B — Post Flight Ana

- Page 498 and 499:

470 March 2007 Appendix C — Weekl

- Page 500 and 501:

16 April 2004—Vehicle is Prepared

- Page 502 and 503:

The electrical power system is full

- Page 504 and 505:

4 JUNE 2004—MISSION UPDATE: DAY 4

- Page 506 and 507:

SQUIDs to detect their rotation spe

- Page 508 and 509:

17 JULY 2004—MISSION UPDATE: DAY

- Page 510 and 511:

indicate that we have reduced the t

- Page 512 and 513:

C.4 Science Mission Phase: 8/27/04

- Page 514 and 515:

• GP-B also has an independent da

- Page 516 and 517:

free suspension parameters to de-tu

- Page 518 and 519:

We have received inquiries about a

- Page 520 and 521:

One of the effects of geomagnetic s

- Page 522 and 523:

egan transmitting, one-by-one, stat

- Page 524 and 525:

28 JANUARY 2005—GRAVITY PROBE B M

- Page 526 and 527:

magnetic pole. This event triggered

- Page 528 and 529:

8 APRIL 2005—GRAVITY PROBE B MISS

- Page 530 and 531:

On Tuesday afternoon (19-April), GP

- Page 532 and 533:

Norway or through the NASA space ne

- Page 534 and 535:

Dewar Temperature: 1.82 kelvin, hol

- Page 536 and 537:

visitors on a tour of the GP-B faci

- Page 538 and 539:

test, we are planning on running fi

- Page 540 and 541:

contractor at the Goddard Space Fli

- Page 542 and 543:

On Wednesday, we visited the star H

- Page 544 and 545:

Gyro Suspension System (GSS): All 4

- Page 546 and 547:

The helium in the dewar has now sur

- Page 548 and 549:

the all the spacecraft status data.

- Page 550 and 551:

522 March 2007 Appendix D — Summa

- Page 552 and 553:

Figure D-2 below shows the distribu

- Page 554 and 555:

DateSeveritySubtypeTitle Descriptio

- Page 556 and 557:

DateSeverity24 26-Apr-04 Obs F Nois

- Page 558 and 559:

DateSeverity40 11-May-04 Obs T Dwel

- Page 560 and 561:

DateSeveritySubtypeTitle Descriptio

- Page 562 and 563:

DateSeverity68 16-Jun-04 Medium Dec

- Page 564 and 565:

DateSeverity84 13-Jul-04 Obs F Slig

- Page 566 and 567:

DateSeveritySubtypeTitle Descriptio

- Page 568 and 569:

DateSeverity116 26-Sep-04 Obs F SG3

- Page 570 and 571:

DateSeverity132 20-Dec-04 Obs F Unc

- Page 572 and 573:

DateSeverity149 5-Mar-05 Obs T Few

- Page 574 and 575:

DateSeverity169 04-Jun-05 Obs F MBE

- Page 576 and 577:

DateSeverity191 04-Oct-05 Obs A GSS

- Page 578 and 579:

550 March 2007 Appendix E — Fligh

- Page 580 and 581:

ReqIDLevel 1CSCDMP DataMgmtProcessi

- Page 582 and 583:

ReqIDLevel 1CSCLevel2 CSC Level 3 C

- Page 584 and 585:

ReqIDLevel 1CSCLevel2 CSC Level 3 C

- Page 586 and 587:

ReqIDLevel 1CSCLevel2 CSC Level 3 C

- Page 588 and 589:

ReqIDLevel 1CSCSRM Solid StateRecor

- Page 590 and 591:

ReqIDLevel 1CSCLevel2 CSC Level 3 C

- Page 592 and 593:

ReqIDLevel 1CSCLevel2 CSC Level 3 C

- Page 594 and 595:

ReqIDLevel 1CSCSRP SafemodeResponse

- Page 596 and 597:

ReqIDLevel 1CSCGUP GSS Processing g

- Page 598 and 599:

570 March 2007 Appendix F — Acron

- Page 600 and 601:

AcronymDefinitionAcronymDefinitionB

- Page 602 and 603:

AcronymDefinitionAcronymDefinitionD

- Page 604 and 605:

AcronymDefinitionAcronymDefinitionF

- Page 606 and 607:

AcronymDefinitionIRUInertial Refere

- Page 608 and 609:

AcronymDefinitionAcronymDefinitionM

- Page 610 and 611:

AcronymPMPMAPMCPMEPMETPMSPMSUPNPoPO

- Page 612 and 613:

AcronymSCMOSCMTSCNSCPASCPMSCRSCSASC

- Page 614 and 615:

AcronymDefinitionAcronymDefinitionT

- Page 616:

588 March 2007 Appendix F — Acron