coal trade bulletin - Clpdigital.org

coal trade bulletin - Clpdigital.org

coal trade bulletin - Clpdigital.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

36 THE COAL TRADE BULLETIN.<br />

found that neither the setting of props nor their<br />

removal will affect the action of the roof.<br />

In general it may be said that so far as the<br />

weight of the roof is concerned the following<br />

dimensions of the pillars apply:<br />

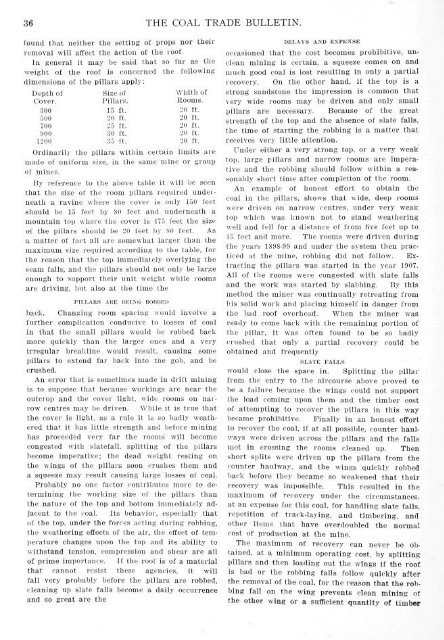

Depth of Size of Width of<br />

Cover. Pillars. Rooms.<br />

300 15 ft. 20 ft.<br />

500 20 ft. 20 ft.<br />

700 25 ft. 20 ft.<br />

900 30 ft. 20 ft.<br />

1200 35 ft. 20 ft.<br />

Ordinarily the pillars within certain limits are<br />

made of uniform size, in the same mine or group<br />

of mines.<br />

By reference to the above table it will be seen<br />

that the size of the room pillars required undeineath<br />

a ravine where the cover is only 150 feet<br />

should be 15 feet by 80 feet ancl underneath a<br />

mountain top where the cover is 175 feet the size<br />

of the pillars should be 20 feet by SO feet. As<br />

a matter of fact all are somewhat larger than the<br />

maximum size required according to the table, for<br />

the reason that the top immediately overlying the<br />

seam falls, and the pillars should not only be large<br />

enough to support their unit weight while rooms<br />

are driving, but also at the time the<br />

PILLARS ARE 11EINO ROBBED<br />

back. Changing room spacing would involve a<br />

further complication conducive to losses of <strong>coal</strong><br />

in that the small pillars would be robbed back<br />

more quickly than the larger ones and a very<br />

irregular breakline would result, causing some<br />

pillars to extend far back into the gob, and be<br />

crushed.<br />

An error that is sometimes made in drift mining<br />

is to suppose that because workings are near the<br />

outcrop and the cover light, wide rooms on narrow<br />

centres may be driven. While it is true that<br />

the cover is light, as a rule it is so badly weathered<br />

that it has little strength and before mining<br />

has proceeded very far the rooms will become<br />

congested with slatefall, splitting of the pillars<br />

become imperative; the dead weight resting on<br />

the wings of the pillars soon crushes them and<br />

a squeeze may result causing large losses of coai.<br />

Probably no one factor contributes more to determining<br />

the working size of the pillars than<br />

the nature of the top and bottom immediately adjacent<br />

to the <strong>coal</strong>. Its behavior, especially that<br />

of the top, under the forces acting during* robbing,<br />

the weathering effects of the air, the effect of temperature<br />

changes upon the top and its ability to<br />

withstand tension, compression and shear are all<br />

of prime importance. If the roof is of a material<br />

that cannot resist these agencies, it will<br />

fall very probably before the pillars are robbed,<br />

cleaning up slate falls become a daily occurrence<br />

and so great are the<br />

DELAYS AND EXPENSE<br />

occasioned that the cost becomes prohibitive, unclean<br />

mining is certain, a squeeze comes on and<br />

much good <strong>coal</strong> is lost resulting in only a partial<br />

recovery. On the other hand, if the top is a<br />

strong sandstone the impression is common that<br />

very wide rooms may be driven and only small<br />

pillars are necessary. Because of the great<br />

strength of the top and the absence of slate falls,<br />

the time of starting the robbing is a matter that<br />

receives very little attention.<br />

Under either a very strong top, or a. very weak<br />

top, large pillars and narrow rooms are imperative<br />

and the robbing should follow within a reasonably<br />

short time after completion of the room.<br />

An example of honest effort to obtain the<br />

<strong>coal</strong> in the pillars, shows that wide, deep rooms<br />

were driven on narrow centres, under very weak<br />

to]) which was known not to stand weathering<br />

well and fell for a distance of from five feet up to<br />

15 feet and more. The rooms were driven during<br />

the years 1898-99 and under the system then practiced<br />

at the mine, robbing did not follow. Extracting<br />

the pillars was started in the year 1907.<br />

All of the rooms were congested with slate falls<br />

and the work was started by slabbing. By this<br />

method the miner was continually retreating from<br />

his solid work and placing himself in danger from<br />

the bad roof overhead. When the miner was<br />

ready to come back with the remaining portion of<br />

the pillar, it was often found to be so badly<br />

crushed that only a partial recovery could be<br />

obtained and frequently<br />

SLATE FALLS<br />

would close the space in. Splitting the pillar<br />

from the entry to the aircourse above proved to<br />

be a failure because the wings could not support<br />

the load coming upon them and the timber cost<br />

of attempting to recover the pillars in this way<br />

became prohibitive. Finally in an honest effort<br />

to recover the <strong>coal</strong>, if at all possible, counter haulways<br />

were driven across the pillars and the falls<br />

met in crossing the rooms cleaned up. Then<br />

short splits were driven up the pillars from the<br />

counter haulway, and the wings quickly robbed<br />

back before they became so weakened that their<br />

recovery was impossible. This resulted in the<br />

maximum of recovery under the circumstances.<br />

at an expense for this <strong>coal</strong>, for handling slate falls,<br />

repetition of track-laying, and timbering, and<br />

other items that have overdoubled the normal<br />

cost of production at the mine.<br />

The maximum of recovery can never be obtained,<br />

at a minimum operating cost, by splitting<br />

pillars and then loading out the wings if the roof<br />

is bad or the robbing falls follow quickly after<br />

the removal of the <strong>coal</strong>, for the reason that the robbing<br />

fall on the wing prevents clean mining of<br />

the other wing or a sufficient quantity of timber