- Page 1 and 2: R 2.1 199^ ^.EN GINEERING DATA TRAN

- Page 3 and 4: Date Received% • I INFORMATION RE

- Page 5 and 6: . SUPPORTING DOCUMENT 1. Total Page

- Page 7 and 8: WHC-SD-W100-TI-003 Rev. 0 EXECUTIVE

- Page 9 and 10: WHC-SD-W100-TI-003 Rev. 0 been achi

- Page 11 and 12: __ _ _ MHC-SIL-yJ3,00-TI-D03 Rev. 0

- Page 13 and 14: F`= WHC-SD-W100-TI-003 Rev. 0 DESCR

- Page 15 and 16: WHC-SD-W100-TI-003 Rev. 0 LIST OF T

- Page 17 and 18: WHC-SD-W100-TI-003 Rev. 0 WASTE REC

- Page 19 and 20: WHC-SD-W100-TI-003 Rev. 0 1.2.1 Fee

- Page 21 and 22: ^s. WHC-SD-W100-TI-003 Rev. 0 conta

- Page 23 and 24: __-'°'2 WHC-SD-W100-TI-003 Rev. 0

- Page 25 and 26: 2.1 REGULATORY FRAMEWORK WHC-SD-W10

- Page 27 and 28: ^..." ;_:.. :.^ .^.y^ WHC-SD-W100-T

- Page 29 and 30: WHC-SD-W100-TI-003 Rev. 0 which the

- Page 31 and 32: kIHC-S^u-Wi"v"u-Ti-u03 Rev. V ,--,,

- Page 33 and 34: WHC-SD-W100-TI-003 Rev. 0 Type 1 wa

- Page 35 and 36: 3.3 TESTING APPROACH WHC-SD-W100-TI

- Page 37 and 38: ^.: fi WNC-SD-W100-TI-003 Rev. 0 Fi

- Page 39 and 40: 4.1 SCREENING TEST RESULTS WHC-SD-W

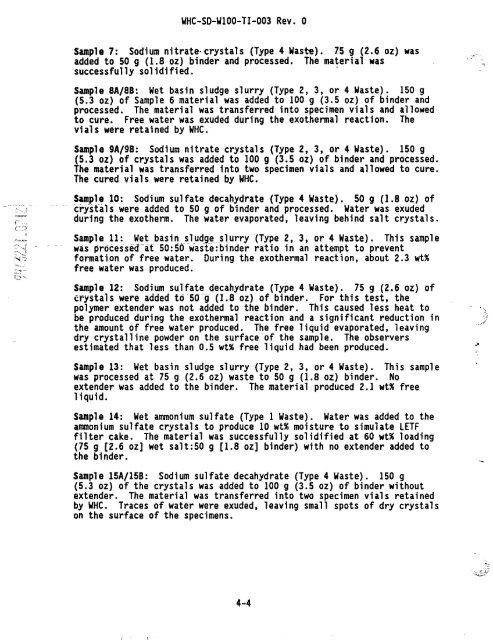

- Page 41: ,^. ----- -- WHC-SD-W100-TI-003 Rev

- Page 45 and 46: p Sam le Compressive Radiation stre

- Page 47 and 48: WHC-SD-W100-TI-003 Rev. 0 Table 4-3

- Page 49 and 50: ..., TESTING RESULTS .^.CSSD-W-1OO-

- Page 51 and 52: A I w ^^',; ^^ ;J ?1Fasf^.}: "q -?

- Page 53 and 54: ;..;: .^:. WHC-SD-W100-TI-003 Rev.

- Page 55 and 56: --- ....ti s..` WHC-SD-WI00-TI-003

- Page 57 and 58: 1.0 INTRODUCTION WHC-SD-W100-TI-003

- Page 59 and 60: WHC-SD-W100-TI-003 Rev. 0 Waste For

- Page 61 and 62: ^-: -- ^ Component Waste Type 1 LET

- Page 63 and 64: .^x. --1vHC-SD iii00- T i-003 Rev.

- Page 65 and 66: WHC-SD-W: JV-TI-VVJ ^cv. v APPENDIX

- Page 67 and 68: ,..^ c:-- z ,.E ^=t ^^ln^l WHC-SD-W

- Page 69 and 70: Scope WHC-SD-W100-TI-003 Rev. 0 Sup

- Page 71 and 72: 00 V F-' Activity and Miltstone Cha

- Page 73 and 74: WHC-SD-W100-TI-003 Rev. 0 Laborator

- Page 75 and 76: WHC-SD-WIOO-TI-003 Rev. 0 APPENDIX

- Page 77 and 78: 16490 Chiaccothe Itoad Chagrin Fall

- Page 79 and 80: ca-. tY•^_E Q . - - StoGkE4uip+!n

- Page 81 and 82: ^.. WHC-SD-W100-TI-003 Rev. 0 . , I

- Page 83 and 84: Waste Type: WHC-SD-W100-TI-003 Rev.

- Page 85 and 86: Stock E quipment Company A Unit of

- Page 87 and 88: G' ,.,. d,_ s WHC-0-W100-TI-003 Rev

- Page 89 and 90: Cx U: r°... .• , .ti Waste Type:

- Page 91 and 92: -. LeachantSolution: Specimen Diame

- Page 93 and 94:

c^1, WHC-SD-W100-TI-003 Rev. 0 THER

- Page 95 and 96:

..... lry" - Stock E a uipment Comp

- Page 97 and 98:

;=. .:^;. WHC-SD-W100-TI-003 Rev< 0

- Page 99 and 100:

(.7 ..^^ -„n f^. [Y^. Waste Type:

- Page 101 and 102:

Date: _ Leachability Time Point Lea

- Page 103 and 104:

23 Ninety ( 90) Day Immersion Test

- Page 105 and 106:

ty ,.. ='`F r...,, b Ly.. Specimen

- Page 107 and 108:

25 BIODEGRADATION TEST PROCEDURE St

- Page 109 and 110:

Date: WHC-SD-W100-TI-003 Rev. 0 BIO

- Page 111 and 112:

^_... ..^^ C:i1 Date: WHC-SD-W100-T

- Page 113 and 114:

Date: WHC-SD-W100-TI-003 Rev. 0 --

- Page 115 and 116:

f-^ -- WHC-SD-W100-TI-003 Rev. 0 2.

- Page 117 and 118:

^-..., 3•0 ASSAY FOR MEI'ALS 3.1

- Page 119 and 120:

t..f f....,.. P....^ .-- ^ : .^ ^-.

- Page 121 and 122:

^c. v 3 0 w.3 cn a v t[ACeRUtIIY IO

- Page 123 and 124:

WHC-SD-W100-TI-003 Rev. 0 APPENDIX

- Page 125 and 126:

WHC-SD-W100-TI-003 Rev. 0 STOCK EQU

- Page 127 and 128:

19 SCOPE AND APPLICATION WHC-SD-W10

- Page 129 and 130:

L:^3 ll Q. 4 AA :'ILTEP.S WHC-0-W10

- Page 131 and 132:

4_T tJrD o,...Ys j ^,.,. WHC-SD-W10

- Page 133 and 134:

WHC-SD-W100-TI-003 Rev. 0 -, Proced

- Page 135 and 136:

WHC-SD-W100-TI-003 Rev. 0 Procedure

- Page 137 and 138:

(FM WHC-SD-W100-TI-003 Rev. 0 Proce

- Page 139 and 140:

C... 6 Wet Waste Sample Contains no

- Page 141 and 142:

^..., . ,.y^ h:.r WHC-SD-WI00-Ti-00

- Page 143 and 144:

:. WHC-SD-W100-TI-003 Rev. 0 TA3i.E

- Page 145 and 146:

^' . WHC-SD-W100-T1-003 Rev. 0 TABL

- Page 147 and 148:

^- ^-> ^ C^Jl I I^t ^.: l WHC-St]-W

- Page 149 and 150:

c. 03 00 r=3 ^t C^' II 6.0 II Calib

- Page 151 and 152:

LY; ^ C=l . ^.^ .^,..,, €:^. MHC-

- Page 153 and 154:

R: C=1 rIj s^ ^ ^.. WHC-SD-YlI00-TI

- Page 155 and 156:

.,,_..1 ---^ - - i-•_E ?*^^ Mater

- Page 157 and 158:

WHC-SD-W100-TI-003 Rev. 0 Dow Chemi

- Page 159 and 160:

^ ±.£:a [7.p -;^ --- --------- WH

- Page 161 and 162:

WHC-S®-hi1.00-T'.-00?, Rev. Dow Ch

- Page 163 and 164:

t;7_7 ,...:: ----------- WHC-SD-W10

- Page 165 and 166:

WHC-SD-W100-TI-003 Rev. 0 Daw M.. u

- Page 167 and 168:

^ ^..rYfl VF •UIYb 1 1 AGA GllS.

- Page 169 and 170:

WHC-SD-W100-TI-003 Rev. 0 APPENDIX

- Page 171 and 172:

CHARACTERIZATION DATA Part A: Overv

- Page 173 and 174:

Grit Specie or MaterialOverall Cont

- Page 175 and 176:

WHC-SD-W100-TI-003 Rev. 0 The incin

- Page 177 and 178:

WHC-SD-W100-TI-003 Rev. 0 183-H BAS

- Page 179 and 180:

WHC-SD-W100-TI-003 Rev. 0 June - Se

- Page 181 and 182:

WHC-SD-W100-TI-003 Rev. 0 BASINS 3

- Page 183 and 184:

WHC-SD-W100-TI-003 Rev. 0 BASINS 3

- Page 185 and 186:

^- WHC-SD-W100-TI-003 Rev. 0 BASIN

- Page 187 and 188:

WHC-SD-W100-TI-003 Rev. 0 ---------

- Page 189 and 190:

J. L. Westcott Page 3 June 1, 1992

- Page 191 and 192:

u...^^, WHC-SD-W100-TI-003 Rev. 0 I

- Page 193 and 194:

•N`^C-Sf1-"d100-71-003 Rev. 0 ,S'

- Page 195 and 196:

CONTAINER /NFORMATlO N: `d"-C-Sn-'w

- Page 197 and 198:

ONTANVER BVFORMA SI7 E: AMOUN=i 8 G

- Page 199 and 200:

LOT WRAP 2A.4 SHEET 7.XLS RECOMMEND

- Page 201 and 202:

LOT WRAP 2A.5 SHEET 8.XLS RECOMMEND

- Page 203 and 204:

.:•n-,,, LOT WRAP 2A.6 SHEET 9.XL

- Page 205 and 206:

LOT WRAP 2A.7 SHEET 10.XLS RECOMMEN

- Page 207 and 208:

PHYSICAL DESCR/PTTON: V-r-S?-W100-T

- Page 209 and 210:

,.: Westinoause Harlford COMM WHC-S

- Page 211 and 212:

O I tA SHEETII.XLS ;, LOT WRAP2A.2

- Page 213 and 214:

CONTAINER /NFORMAT/ON: DOSE: SIZE:

- Page 215 and 216:

PU33-11-1992 09:48 FROM EDS/qRI$ir

- Page 217 and 218:

LOT WRAP 2A 10 Slf-EET 14.)C,S RECO

- Page 219 and 220:

qN i: 105N-89-1097 105N-89-1098 105

- Page 221 and 222:

SIZE: DOSE: 5 GAL 1 1@15 Mr 30 GAL

- Page 223 and 224:

WHC-SD-W100-TI-003 Rev. 0 Westtngho

- Page 225 and 226:

LOT WRAP A2.14 SHEET 18.XLS RECOMME

- Page 227 and 228:

---- - LOT WRAP ZA.13 SHEET 17.XLS

- Page 229 and 230:

n .-.^..-n..^^- .. ... .dJ. ^ ShIEE

- Page 231 and 232:

--^ WHC-SD-W100-TI-003 Rev. 0 APPEN

- Page 233 and 234:

WHC-SD-W100-TI-003 Rev. 0 Westingho

- Page 235 and 236:

Table 1 Candidate Waste Forms Absor

- Page 237 and 238:

--- -Aauaspt and Pe-liroset WHC-SD-

- Page 239 and 240:

- '^ - qev. r' Literature Search WR

- Page 241 and 242:

Dow Polymer WHC-SD-W100-TI-003 Rev.

- Page 243 and 244:

L im e Literature Search WRAP 2A Pa

- Page 245 and 246:

The report compares the 7eachabilit

- Page 247 and 248:

J. L. Westcott Page 2 May 29, 1992

- Page 249 and 250:

Package #1: Package #2: WHC-SD-W100

- Page 251 and 252:

WHC-SD-W100-TI-003 Rev. 0 SURVEY OF

- Page 253 and 254:

f ..;' WHC-SD-W100-TI-003 Rev. 0 A

- Page 255 and 256:

WHC-SD-W100-TI-003 Rev. 0 SURVEY OF

- Page 257 and 258:

WHC-SD-W100-TI-003 Rev. 0 commercia

- Page 259 and 260:

WHC-SD-W100-TI-003 Revo 0 Bibliogra

- Page 261 and 262:

WHC-SD-W100-TI-003 Rev. 0 A. P. Tos

- Page 263 and 264:

OAK R1DGE NATIONAL LABORATORY OPERA

- Page 265 and 266:

WHC-SD-W100-TI-003 Rev. 0 SURVEY OF

- Page 267 and 268:

WHC-SD-W100-TI-003 Rev. 0 commercia

- Page 269 and 270:

WHC-SD-W100-TI-003 Revo 0 A report

- Page 271 and 272:

WHC-SD-W100-TI-003 Rev. 0 impermeab

- Page 273 and 274:

WHC-SD-W100-TI-003 Rev. 0 reprocess

- Page 275 and 276:

WHC-SD-W100-TI-003 Rev. 0 STR?.THGI

- Page 277 and 278:

Contained under four reports: WHC-S

- Page 279 and 280:

^.yo F-SD-W"00-7-003 Rev. 0 THERMOS

- Page 281 and 282:

WHC-SD-W100-TI-003 Rev. 0 The techn

- Page 283 and 284:

loomi^^lC& 111111111111F .^^.\ West

- Page 285 and 286:

^u9^c ?fi. ...^ .._-, WHC-SD-W100-T

- Page 287 and 288:

Stock Equipment Company WHC-SD-WI00

- Page 289 and 290:

^ i w STOCK EOUIPMENT COMPANY 14-OC

- Page 291 and 292:

\. . 1 .: lh,lf^ LEACH / IMMERSIONI

- Page 293 and 294:

^;- v.4'? Sampls ID L781 Elsment CO

- Page 295 and 296:

4.a

- Page 297 and 298:

Sanp)a ID L781 Elamant STRONTIUM Ma

- Page 299 and 300:

.^ "-; SampI81D L3B2 Z e"- ^.;;. Sa

- Page 301 and 302:

Sample 10 L3B1 Elsmant CESIUM Matri

- Page 303 and 304:

Sample ID W B1 Elemant STRONIIUM Ma

- Page 305 and 306:

Westinghouse Hanford Company 2355 S

- Page 307 and 308:

--- - ftCR-e4Uip1P1eFf Company WHC-

- Page 309 and 310:

WHC-SD-W100-TI-003 Rev. 0 Russ Czel

- Page 311 and 312:

Stock Equipment Company 3:0 -SCFIED

- Page 313 and 314:

THERMAL CYCLING SAMPLES BEFORE THE

- Page 315 and 316:

BIODEGRADATION SAMPLES BEFORE THE S

- Page 317 and 318:

C/ 0D OC M1 0, ^yII i..) d tl ^ a I

- Page 319 and 320:

T 1 A w ^ • $ ^py yf ; pp V ^ py

- Page 321 and 322:

T 1 A ^ !^^ + ^ i •^^w^:rwwwwrpR^

- Page 323 and 324:

'i A v lf^. j^^ u e e - - I I I a i

- Page 325 and 326:

0 > d C.) O O F- 0 0 3 G NI U 3 ^ c

- Page 327 and 328:

en a-. p g aQ i ^ rr it - l r rF e^

- Page 329 and 330:

' iO`F*'P\^ Westinghouse Hanford Co

- Page 331 and 332:

Stock Equipment Company 1.0 SUMMARY

- Page 333 and 334:

Stock Equipment Company WHC-SD-W100

- Page 335 and 336:

2a0 SCHEDULE Activitv - Prepare Wor

- Page 337 and 338:

T 1 o+ THERMAL CYCLWG SAMPLES BEFOR

- Page 339 and 340:

T 1 OI 80 70 U 60 VJ w 50 w 0 40 30

- Page 341 and 342:

^ °' cn l .:. U CD w a: w r' i ^ I

- Page 343 and 344:

SAMPLE ID Li-117 L1-118 L1-19 L3-17

- Page 345 and 346:

T °,w ^ - : C s 0 n a ^^ s ^ i ^-

- Page 347 and 348:

71 I V y,,} ^ • 5il i ^ ^^ ^ ^ ^

- Page 349 and 350:

0 a^ on O O M F- 1OCD 3 1 G N^ U il

- Page 351 and 352:

O > W C f.) O O 1-- ^ O HI 6./ 3 ^

- Page 353 and 354:

0 > ar oe M 0 c C3, I O c V 3 ^I d

- Page 355 and 356:

TI V 40 IN s i s : s ^l l i " p p l

- Page 357 and 358:

WHC-SD-W100-TI-003 Rev. 0 APPENDIX

- Page 359 and 360:

WHC-SD-W100-TI-003 Rev. 0 _QVrDvrru

- Page 361 and 362:

^-_- .,:... WHC-SD-W100-TI-003 Rev.

- Page 363 and 364:

Ceramics and glass WHC-SD-W200-TI-0

- Page 365 and 366:

,. ., Extruder/melter WHC-SD-W100-T