Condair Dual 2 manual.pdf

Condair Dual 2 manual.pdf

Condair Dual 2 manual.pdf

- TAGS

- condair

- dual

- biossol.gr

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

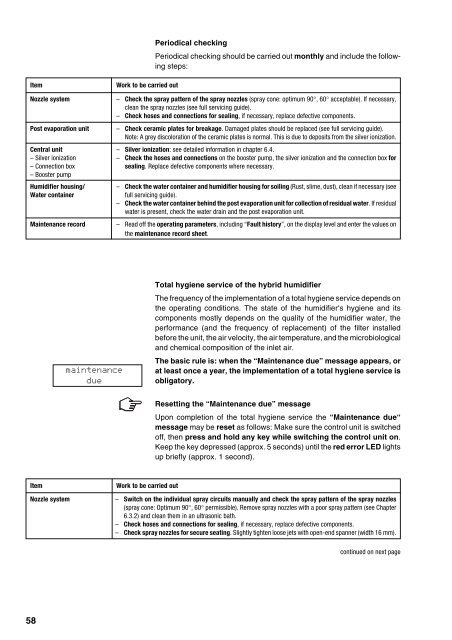

Item Work to be carried out<br />

Nozzle system – Check the spray pattern of the spray nozzles (spray cone: optimum 90°, 60° acceptable). If necessary,<br />

clean the spray nozzles (see full servicing guide).<br />

– Check hoses and connections for sealing, if necessary, replace defective components.<br />

Post evaporation unit – Check ceramic plates for breakage. Damaged plates should be replaced (see full servicing guide).<br />

Note: A grey discoloration of the ceramic plates is normal. This is due to deposits from the silver ionization.<br />

Central unit<br />

– Silver ionization<br />

– Connection box<br />

– Booster pump<br />

Humidifier housing/<br />

Water container<br />

58<br />

Periodical checking<br />

Periodical checking should be carried out monthly and include the following<br />

steps:<br />

– Silver ionization: see detailed information in chapter 6.4.<br />

– Check the hoses and connections on the booster pump, the silver ionization and the connection box for<br />

sealing. Replace defective components where necessary.<br />

– Check the water container and humidifier housing for soiling (Rust, slime, dust), clean if necessary (see<br />

full servicing guide).<br />

– Check the water container behind the post evaporation unit for collection of residual water. If residual<br />

water is present, check the water drain and the post evaporation unit.<br />

Maintenance record – Read off the operating parameters, including “Fault history”, on the display level and enter the values on<br />

the maintenance record sheet.<br />

maintenance<br />

due<br />

Item Work to be carried out<br />

Total hygiene service of the hybrid humidifier<br />

The frequency of the implementation of a total hygiene service depends on<br />

the operating conditions. The state of the humidifier‘s hygiene and its<br />

components mostly depends on the quality of the humidifier water, the<br />

performance (and the frequency of replacement) of the filter installed<br />

before the unit, the air velocity, the air temperature, and the microbiological<br />

and chemical composition of the inlet air.<br />

The basic rule is: when the “Maintenance due” message appears, or<br />

at least once a year, the implementation of a total hygiene service is<br />

obligatory.<br />

Resetting the “Maintenance due” message<br />

Upon completion of the total hygiene service the “Maintenance due“<br />

message may be reset as follows: Make sure the control unit is switched<br />

off, then press and hold any key while switching the control unit on.<br />

Keep the key depressed (approx. 5 seconds) until the red error LED lights<br />

up briefly (approx. 1 second).<br />

Nozzle system – Switch on the individual spray circuits <strong>manual</strong>ly and check the spray pattern of the spray nozzles<br />

(spray cone: Optimum 90°, 60° permissible). Remove spray nozzles with a poor spray pattern (see Chapter<br />

6.3.2) and clean them in an ultrasonic bath.<br />

– Check hoses and connections for sealing, if necessary, replace defective components.<br />

– Check spray nozzles for secure seating. Slightly tighten loose jets with open-end spanner (width 16 mm).<br />

continued on next page