Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COAL<br />

The dramatic increase in cost for the IGCC case<br />

shows that using absorption on the gas turbine<br />

exhaust is not an effective way to capture C02.<br />

Hence alternative schemes are based on treating<br />

the gasifier product gas to concentrate the car<br />

bon before combustion and take advantage of<br />

the operating pressure. Therefore an additional<br />

exercise looked at an IGCC system where the<br />

fuel gas was shifted in a high and a low tempera<br />

ture shift reactor and then cleaned in a Selexol<br />

unit (IGCC Selexol). The H2S and C02 leave the<br />

unit in separate streams. The cleaned fuel gas is<br />

burned in the gas turbines. Results are shown in<br />

the last column of Table 1 .<br />

Physical absorption using Selexol is the most<br />

appropriate technique to remove C02 from IGCC<br />

fuel gases. A higher gasification pressure will<br />

facilitate the C02 removal and increase the over<br />

all power production efficiency. The use of more<br />

advanced gas turbines could result in an in<br />

crease in the overall efficiency.<br />

Comparing the Capture Options<br />

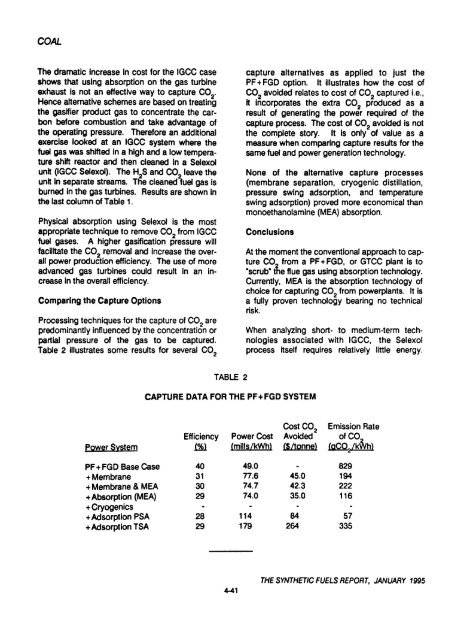

Processing techniques for the capture of C02 are<br />

predominantly influenced by the concentration or<br />

partial pressure of the gas to be captured.<br />

Table 2 illustrates some results for several CO<br />

Power System<br />

PF+FGD Base Case<br />

+ Membrane<br />

+ Membrane & MEA<br />

+ Absorption (MEA)<br />

+ Cryogenics<br />

+ Adsorption PSA<br />

+ Adsorption TSA<br />

TABLE 2<br />

capture alternatives as applied to just the<br />

PF+FGD option. It illustrates how the cost of<br />

C02 avoided relates to cost of C02 captured i.e.,<br />

it incorporates the extra C02 produced as a<br />

result of generating the power required of the<br />

capture process. The cost of C02 avoided is not<br />

the complete story. It is only of value as a<br />

measure when comparing capture results for the<br />

same fuel and power generation technology.<br />

None of the alternative capture processes<br />

(membrane separation, cryogenic distillation,<br />

pressure swing adsorption, and temperature<br />

swing adsorption)<br />

proved more economical than<br />

monoethanolamine (MEA) absorption.<br />

Conclusions<br />

At the moment the conventional approach to cap<br />

ture CO from a PF+FGD, or GTCC plant is to<br />

"scrub"<br />

the flue gas using absorption technology.<br />

Currently, MEA is the absorption technology of<br />

choice for capturing from powerplants. It is<br />

C02<br />

a fully proven technology bearing no technical<br />

risk.<br />

When analyzing short- to medium-term tech<br />

nologies associated with IGCC, the Selexol<br />

process itself requires relatively<br />

CAPTURE DATA FOR THE PF+FGD SYSTEM<br />

Efficiency<br />

m<br />

40<br />

31<br />

30<br />

29<br />

28<br />

29<br />

4-41<br />

Power Cost<br />

(mills/kWm<br />

49.0<br />

77.6<br />

74.7<br />

74.0<br />

114<br />

179<br />

Cost C02<br />

Avoided<br />

($/tonne)<br />

45.0<br />

42.3<br />

35.0<br />

84<br />

264<br />

Emission Rate<br />

ofC02<br />

(oCOa/KWTi)<br />

829<br />

194<br />

222<br />

116<br />

57<br />

335<br />

little energy.<br />

THE SYNTHETIC FUELS REPORT, JANUARY 1995

![pace SrntfletIc fne]its report - Alliance Digital Repository](https://img.yumpu.com/10493335/1/190x245/pace-srntfletic-fneits-report-alliance-digital-repository.jpg?quality=85)