Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OIL SHALE<br />

native to severe hydrotreatment for the removal<br />

of refractory aromatic nitrogen compounds from<br />

hydrotreated shale oils. The US-Y zeolite shows<br />

high selectivity toward amines and N<br />

heterocycles and adsorbs them efficiently even in<br />

the presence of large concentrations of saturated<br />

and aromatic hydrocarbons.<br />

The zeolite containing the adsorbed N<br />

heterocycles is readily separated by gravitational<br />

settling and regenerated for reuse by burning off<br />

the adsorbed organics. The high nitrogen con<br />

tent of the adsorbed organics may cause some<br />

combustion of the<br />

NO to be formed during<br />

zeolite, so appropriate stack gas scrubbing may<br />

be required (as it is for the ammonia and<br />

hydrogen sulfide produced by hydrotreatment).<br />

Because the N compounds constitute a very<br />

small proportion of a mildly hydrotreated oil, it<br />

would be more economic to sacrifice these com<br />

pounds by zeolite adsorption and combustion<br />

rather than to use the alternative procedure of<br />

very severe hydrotreatment, which substantially<br />

lowers the value and yield of total liquid products<br />

through loss of aromaticity, cracking and coking.<br />

####<br />

GE PATENTS RADIO FREQUENCY IN SITU<br />

RECOVERY METHOD<br />

United States Patent 5,236,039 issued to<br />

W. Edeistein et al., and assigned to General<br />

Electric Company, describes a new method of<br />

arranging electrodes for a radio-frequency, in situ<br />

recovery<br />

method for oil shale.<br />

A system for extracting oil in situ from a deep<br />

hydrocarbon bearing layer employs a master os<br />

cillator for producing a fundamental frequency, a<br />

plurality of radiofrequency (RF) heating<br />

electrodes, and a matching network. The con<br />

ductive electrodes are situated in a rectangular<br />

pattern. Production wells are provided at the cen<br />

ter of each rectangular pattern for collecting the<br />

oU and producing it at the surface. The currents<br />

among the electrode array uniformly<br />

heat the oil-<br />

2-15<br />

rich layer in situ to pyrolysis. Oil reaches the<br />

production wells by fracturing the hydrocarbon<br />

bearing layer and creating permeable paths to<br />

the production wells.<br />

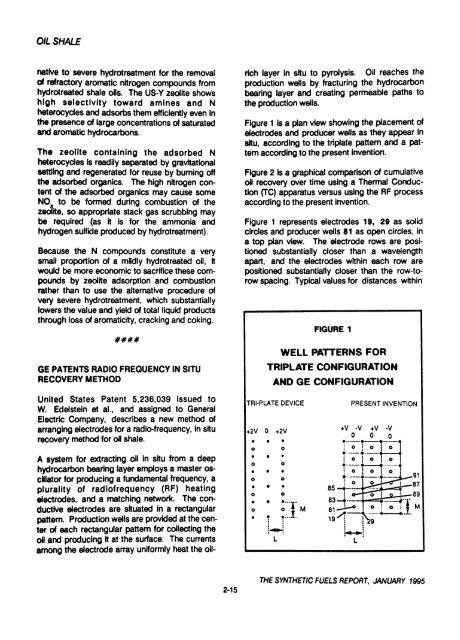

Figure 1 is a plan view showing the placement of<br />

electrodes and producer wells as they appear in<br />

situ, according to the tripiate pattern and a pat<br />

tern according to the present invention.<br />

Figure 2 is a graphical comparison of cumulative<br />

oil recovery over time using a Thermal Conduc<br />

tion (TC) apparatus versus using the RF process<br />

to the present invention.<br />

according<br />

Figure 1 represents electrodes 19, 29 as solid<br />

circles and producer wells 81 as open circles, in<br />

a top plan view. The electrode rows are posi<br />

tioned substantially<br />

closer than a wavelength<br />

apart, and the electrodes within each row are<br />

positioned substantially<br />

closer than the row-to-<br />

row spacing. Typical values for distances within<br />

FIGURE 1<br />

WELL PATTERNS FOR<br />

TRIPLATE CONFIGURATION<br />

AND GE CONFIGURATION<br />

TRI-PLATE DEVICE<br />

+2V 0 +2V<br />

o<br />

of<br />

J...I.<br />

M<br />

PRESENT INVENTION<br />

?V -V +V -V<br />

0 0 Q<br />

I<br />

,<br />

o t<br />

|<br />

j<br />

f<br />

o I<br />

1<br />

o<br />

"<br />

o j o | e<br />

THE SYNTHETIC FUELS REPORT, JANUARY 1995

![pace SrntfletIc fne]its report - Alliance Digital Repository](https://img.yumpu.com/10493335/1/190x245/pace-srntfletic-fneits-report-alliance-digital-repository.jpg?quality=85)