Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

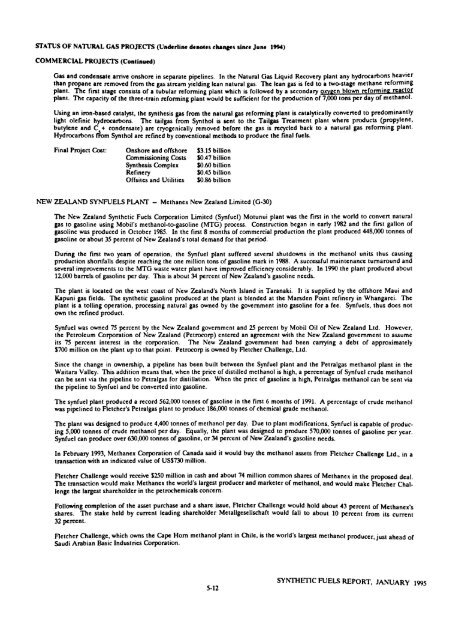

STATUS OF NATURAL GAS PROJECTS (Underline denotes changes since June 1994)<br />

COMMERCIAL PROJECTS (Continued)<br />

Gas and condensate arrive onshore in separate pipelines. In the Natural Gas Liquid Recovery plant any hydrocarbons heavier<br />

than propane are removed from the gas stream yielding lean natural gas. The lean gas is fed to a two-stage methane reforming<br />

plant. The first stage consists of a tubular reforming plant which is followed by a secondary oxygen blown reforming reactor<br />

plant. The capacity of the three-train reforming plant would be sufficient for the production of 7,000 tons per of methanol.<br />

day<br />

Using an iron-based catalyst, the synthesis gas from the natural gas reforming plant is catalytically converted to predominantly<br />

light olefinic hydrocarbons. The tailgas from Synthol is sent to the Tailgas Treatment plant where products (propylene,<br />

butylene and C + condensate) are cryogenically removed before the gas is recycled back to a natural gas plant.<br />

reforming<br />

Hydrocarbons from Synthol are refined by conventional methods to produce the final fuels.<br />

Final Project Cost: Onshore and offshore $3.15 billion<br />

Commissioning Costs $0.47 billion<br />

Synthesis Complex $0.60 billion<br />

$0.45 billion<br />

Refinery<br />

Offsites and Utilities $0.86 billion<br />

NEW ZEALAND SYNFUELS PLANT - Methanex New Zealand Limited (G-30)<br />

The New Zealand Synthetic Fuels Corporation Limited (Synfuel) Motunui plant was the first in the world to convert natural<br />

gas to gasoline using Mobil's methanol-to-gasoline (MTG) process. Construction began in early 1982 and the first gallon of<br />

gasoline was produced in October 1985. In the first 8 months of commercial production the plant produced 448,000 tonnes of<br />

gasoline or about 35 percent of New Zealand's total demand for that period.<br />

During the first two years of operation, the Synfuel plant suffered several shutdowns in the methanol units thus causing<br />

production shortfalls despite reaching the one million tons of gasoline mark in 1988. A successful maintenance turnaround and<br />

several improvements to the MTG waste water plant have improved efficiency considerably. In 1990 the plant produced about<br />

12,000 barrels of gasoline per day. This is about 34 percent of New Zealand's gasoline needs.<br />

The plant is located on the west coast of New Zealand's North Island in Taranaki. It is supplied by the offshore Maui and<br />

Kapuni gas fields. The synthetic gasoline produced at the plant is blended at the Marsden Point refinery in Whangarei. The<br />

plant is a tolling operation, processing natural gas owned by the government into gasoline for a fee. Synfuels, thus does not<br />

own the refined product.<br />

Synfuel was owned 75 percent by the New Zealand government and 25 percent by Mobil Oil of New Zealand Ltd. However,<br />

the Petroleum Corporation of New Zealand (Petrocorp) entered an agreement with the New Zealand government to assume<br />

its 75 percent interest in the corporation. The New Zealand government had been carrying a debt of approximately<br />

$700 million on the plant up to that point. Petrocorp is owned by Fletcher Challenge, Ltd.<br />

Since the change in ownership, a pipeline has been built between the Synfuel plant and the Petralgas methanol plant in the<br />

Waitara Valley. This addition means that, when the price of distilled methanol is high, a percentage of Synfuel crude methanol<br />

can be sent via the pipeline to Petralgas for distillation. When the price of gasoline is high, Petralgas methanol can be sent via<br />

the pipeline to Synfuel and be converted into gasoline.<br />

The synfuel plant produced a record 562,000 tonnes of gasoline in the first 6 months of 1991. A percentage of crude methanol<br />

was pipelined to Fletcher's Petralgas plant to produce 186,000 tonnes of chemical grade methanol.<br />

The plant was designed to produce 4,400 tonnes of methanol per day. Due to plant modifications, Synfuel is capable of produc<br />

ing 5,000 tonnes of crude methanol per day. Equally, the plant was designed to produce 570,000 tonnes of gasoline per year.<br />

Synfuel can produce over 630,000 tonnes of gasoline, or 34 percent of New Zealand's gasoline needs.<br />

In February 1993, Methanex Corporation of Canada said it would buy the methanol assets from Fletcher Challenge Ltd., in a<br />

transaction with an indicated value of US$730 million.<br />

Fletcher Challenge would receive $250 million in cash and about 74 million common shares of Methanex in the proposed deal.<br />

The transaction would make Methanex the world's largest producer and marketer of methanol, and would make Fletcher Chal<br />

lenge the largest shareholder in the petrochemicals concern.<br />

Following completion of the asset purchase and a share issue, Fletcher Challenge would hold about 43 percent of Methanex's<br />

shares. The stake held by current leading shareholder Metallgescllschaft would fall to about 10 percent from its current<br />

32 percent.<br />

Fletcher Challenge, which owns the Cape Horn methanol plant in Chile, is the world's largest methanol producer, just ahead of<br />

Saudi Arabian Basic Industries Corporation.<br />

5-12<br />

SYNTHETIC FUELS REPORT, JANUARY 1995

![pace SrntfletIc fne]its report - Alliance Digital Repository](https://img.yumpu.com/10493335/1/190x245/pace-srntfletic-fneits-report-alliance-digital-repository.jpg?quality=85)