Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NATURAL GAS<br />

The BNL process employs a homogeneous Ni<br />

catalyst and alkoxide in an organic solvent, while<br />

methanol synthesis via MF employs a mixture of<br />

copper-based oxide and alkoxide as a catalyst.<br />

Both processes are operated at around 373 K,<br />

where high equilibrium conversion of carbon<br />

monoxide to methanol is expected. The<br />

processes have been reported to show excellent<br />

activity even at such low temperatures.<br />

S. Ohyama of the Central Research Institute of<br />

Electric Power Industry in Tokyo, Japan has ex<br />

amined the catalytic activities of these two<br />

processes and assessed their possibilities as in<br />

dustrial processes in terms of Space Time Yield<br />

(STY). He discussed his findings at the Sym<br />

posium on Alternative Routes for the Production<br />

of Fuels, held as part of the 208th American<br />

Chemical Society National Meeting held in<br />

Washington, D.C. in August.<br />

BNL Methanol Process<br />

Methanol was formed quite selectively<br />

over the<br />

BNL catalysts at 353-433 K and 1 .1-5.0 MPa of ini<br />

tial pressure. The STY with the BNL catalysts<br />

varied with Ni concentration in the catalyst sys<br />

tem and reached 0.89 kilograms per liter per hour<br />

at the optimum concentration. At 433 K, the BNL<br />

catalysts yielded almost 90 percent for CO con<br />

version and over 99 percent for selectivity to<br />

methanol. Because the catalyst is highly active<br />

even at temperatures much lower than the operat<br />

ing<br />

temperature of the conventional methanol<br />

process (503-543 K), it should be possible to<br />

eliminate recycling facilities for unconverted gas,<br />

which would reduce the production cost of<br />

methanol.<br />

Methanol Synthesis via MF<br />

Methanol was formed rapidly<br />

using<br />

at around 373 K<br />

a mixture of copper-based oxide and<br />

alkoxide. Using catalyst N203SD and potassium<br />

methoxkJe, CO conversion was 87-94 percent,<br />

to methanol was 87-98 percent.<br />

selectivity<br />

Higher temperatures and higher initial pressures<br />

enhanced methanol productivity, while lower tem-<br />

5-6<br />

peratures and higher pressures Increased methyl<br />

formate formation.<br />

STY Evaluation of Low-Temperature Methanol<br />

Synthesis<br />

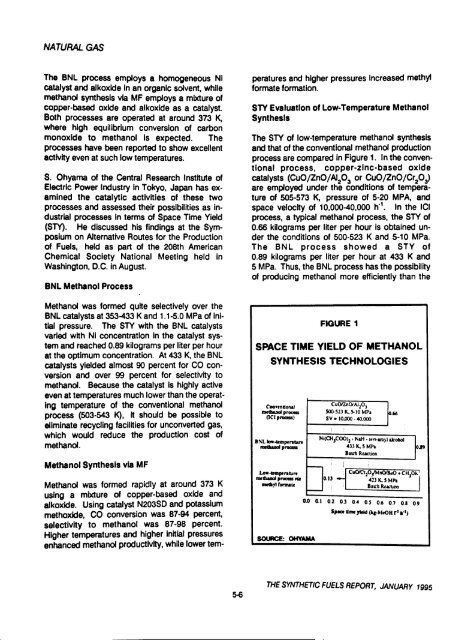

The STY of low-temperature methanol synthesis<br />

and that of the conventional methanol production<br />

process are compared in Figure 1. In the conven<br />

tional process, copper-zinc-based oxide<br />

catalysts or (CuO/ZnO/AI203 CuO/ZnO/Cr203)<br />

are employed under the conditions of tempera<br />

ture of 505-573 K, pressure of 5-20 MPA, and<br />

space velocity<br />

of 10,000-40,000 h*\ In the ICI<br />

process, a typical methanol process, the STY of<br />

0.66 kilograms per liter per hour is obtained un<br />

der the conditions of 500-523 K and 5-10 MPa.<br />

The BNL process showed a STY of<br />

0.89 kilograms per liter per hour at 433 K and<br />

5 MPa. Thus, the BNL process has the possibility<br />

of producing methanol more efficiently than the<br />

FIGURE 1<br />

SPACE TIME YIELD OF METHANOL<br />

SYNTHESIS TECHNOLOGIES<br />

Conventional<br />

methanol process<br />

(ICI process)<br />

BVL km-temperature<br />

methanol process<br />

Lo -temperahire<br />

methanoi process ria<br />

methyl formate<br />

SOURCE: OHYAMA<br />

CuCVZnOAl2Oj<br />

500-523 K, 5-10 MPa<br />

- SV 10.000 40.000<br />

0.66<br />

-<br />

Ni(CH3CCX))2 KaH -<br />

trn-vay\ alcohol<br />

433K.5MP1<br />

0.13 -<br />

Batrt Reaction<br />

CuCyCr20yMnOB40 ? CH,OK<br />

423 K. 5 MPa<br />

Baicb lUaoioo<br />

0.0 0.1 0.2 0.3 04 05 06 07 0 09<br />

Space Urne yield (kf-MeOH r1<br />

r1)<br />

0J9<br />

THE SYNTHETIC FUELS REPORT, JANUARY 1995

![pace SrntfletIc fne]its report - Alliance Digital Repository](https://img.yumpu.com/10493335/1/190x245/pace-srntfletic-fneits-report-alliance-digital-repository.jpg?quality=85)