Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Ikelic - Alliance Digital Repository

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

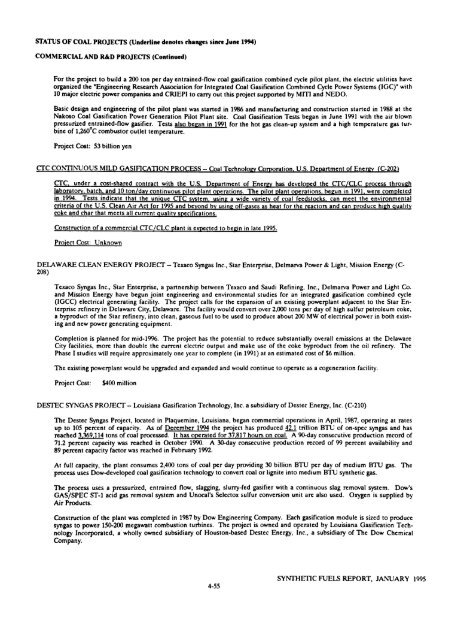

STATUS OF COAL PROJECTS (Underline denotes changes since June 1994)<br />

COMMERCIAL AND R&D PROJECTS (Continued)<br />

For the project to build a 200 ton per entrained-flow day coal gasification combined cycle pilot plant, the electric utilities have<br />

organized the "Engineering Research Association for Integrated Coal Gasification Combined Cycle Power Systems (IGC)"<br />

with<br />

10 major electric power companies and CRIEPI to carry out this project supported by MITI and NEDO.<br />

Basic design and engineering of the pilot plant was started in 1986 and manufacturing and construction started in 1988 at the<br />

Nakoso Coal Gasification Power Generation Pilot Plant site. Coal Gasification Tests began in June 1991 with the air blown<br />

pressurized entrained-flow gasifier. Tests also began in 1991 for the hot gas clean-up system and a high temperature gas tur<br />

bine of 1,260C combustor outlet temperature.<br />

Project Cost: 53 billion yen<br />

CTC CONTINUOUS MILD - GASIFICATION PROCESS Coal<br />

Technology Corporation. U.S. Department of Energy (C-202)<br />

CTC. under a cost-shared contract with the U.S. Department of Energy has developed the CTC/CLC process through<br />

laboratory, batch, and 10 ton/day continuous pilot plant operations. The pilot plant operations, begun in 1991. were completed<br />

in 1994. Tests indicate that the unique CTC system, using a wide variety of coal feedstocks, can meet the environmental<br />

criteria of the U.S. Clean Air Act for 1995 and beyond bv using off-gases as heat for the reactors and can produce high quality<br />

coke and char that meets all current quality specifications.<br />

Construction of a commercial CTC/CLC plant is expected to begin in late 1995.<br />

Project Cost: Unknown<br />

- DELAWARE CLEAN ENERGY PROJECT Texaco<br />

208)<br />

Syngas Inc., Star Enterprise, Delmarva Power & Light, Mission Energy (C-<br />

Texaco Syngas Inc., Star Enterprise, a partnership between Texaco and Saudi Refining, Inc., Delmarva Power and Light Co.<br />

and Mission Energy have begun joint engineering and environmental studies for an integrated gasification combined cycle<br />

(IGCC) electrical generating facility. The project calls for the expansion of an powerplant existing adjacent to the Star En<br />

terprise refinery in Delaware City, Delaware. The facility would convert over 2,000 tons per day of high sulfur petroleum coke,<br />

a byproduct of the Star refinery, into clean, gaseous fuel to be used to produce about 200 MW of electrical power in both exist<br />

ing and new power generating equipment.<br />

Completion is planned for mid-1996. The project has the potential to reduce substantially overall emissions at the Delaware<br />

more than double the current electric output and make use of the coke byproduct from the oil refinery. The<br />

City facilities,<br />

Phase I studies will require approximately one year to complete (in 1991) at an estimated cost of $6 million.<br />

The existing powerplant would be upgraded and expanded and would continue to operate as a cogeneration facility.<br />

Project Cost: $400 million<br />

- DESTEC SYNGAS PROJECT Louisiana<br />

Gasification Technology, Inc. a subsidiary of Destec Energy, Inc. (C-210)<br />

The Destec Syngas Project, located in Plaquemine, Louisiana, began commercial operations in April, 1987, operating at rates<br />

up to 105 percent of capacity. As of December 1994 the project has produced 42.1 trillion BTU of on-spec syngas and has<br />

reached 3.369.1 14 tons of coal processed. It has operated for 37.817 hours on coal. A 90-day consecutive production record of<br />

71.2 percent capacity was reached in October 1990. A 30-day consecutive production record of 99 percent availability and<br />

89 percent capacity factor was reached in February 1992.<br />

At full capacity, the plant consumes 2,400 tons of coal per day providing 30 billion BTU per day of medium BTU gas. The<br />

process uses Dow-developed coal gasification technology to convert coal or lignite into medium BTU synthetic gas.<br />

The process uses a pressurized, entrained flow, slagging, slurry-fed gasifier with a continuous slag removal system. Dow's<br />

GAS/SPEC ST-1 acid gas removal system and Unocal's Selectox sulfur conversion unit are also used. Oxygen is supplied by<br />

Air Products.<br />

Construction of the plant was completed in 1987 by Dow Engineering Company. Each gasification module is sized to produce<br />

syngas to power 150-200 megawatt combustion turbines. The project is owned and operated by Louisiana Gasification Tech<br />

nology Incorporated, a wholly owned subsidiary of Houston-based Destec Energy, Inc., a subsidiary of The Dow Chemical<br />

Company.<br />

4-55<br />

SYNTHETIC FUELS REPORT, JANUARY 1995

![pace SrntfletIc fne]its report - Alliance Digital Repository](https://img.yumpu.com/10493335/1/190x245/pace-srntfletic-fneits-report-alliance-digital-repository.jpg?quality=85)