- Page 1 and 2:

NUM AUTOMATIC CONTROL FUNCTION PROG

- Page 3 and 4:

Table of Contents Table of Contents

- Page 5 and 6:

Table of Contents 9 Analogue Inputs

- Page 7 and 8:

Record of Revisions Record of Revis

- Page 9 and 10:

Date Revision Reason for revisions

- Page 11 and 12:

Structure of the NUM 1020/1040/1060

- Page 13 and 14:

Automatic Control Function Programm

- Page 15 and 16:

CHAPTER 8 TRANSPARENT MODE CHAPTER

- Page 17 and 18:

CHAPTER 16 PROGRAMMING IN C LANGUAG

- Page 19 and 20:

Use of the Automatic Control Functi

- Page 21 and 22:

Presentation of the Automatic Contr

- Page 23 and 24:

1.1 General Presentation of the Aut

- Page 25 and 26:

AXIS 1 INTERFACE AXIS 2 AXIS 3 AXIS

- Page 27 and 28:

µ p 68020 SYSTEM BUS BUS INTERFACE

- Page 29 and 30:

Structure of an Application 2 Struc

- Page 31 and 32:

2.1 General The machine processor c

- Page 33 and 34:

2.1.1.3 «System» I/O Card Refresh

- Page 35 and 36:

Operation of the Background Tasks N

- Page 37 and 38:

2.1.2.4 Real-Time Tasks Structure o

- Page 39 and 40:

2.1.3.2 1060 Series II- UCSII Syste

- Page 41 and 42:

2.2 Structure of an Application Str

- Page 43 and 44:

2.3 Structure of a Ladder Module -

- Page 45 and 46:

Variables 3 Variables 3.1 Principle

- Page 47 and 48:

Variables 3.8.2.19 Backward of Forw

- Page 49 and 50:

3.1 Principle of Exchanges Variable

- Page 51 and 52:

Examples %M9 points to byte 9 of th

- Page 53 and 54:

3.7 I/O Card Interface Variables %I

- Page 55 and 56:

3.7.3.2 Card Status %Irc3C.W Variab

- Page 57 and 58:

A configuration change requires mov

- Page 59 and 60:

3.7.5 Physical Organisation of Vari

- Page 61 and 62:

3.7.6 Rack and Card Identifiers 3.7

- Page 63 and 64:

3.7.8 Image Part of the 32 Discrete

- Page 65 and 66:

%Qrc00.0 to %Qrc02.7 %Irc00.0 to %I

- Page 67 and 68:

%Qrc03.0 to %Qrc05.7 2nd relay modu

- Page 69 and 70:

3.7.12 Image Part of the Extension

- Page 71 and 72:

3.7.13 Image Part of the Compact Pa

- Page 73 and 74:

3.8 CNC I/O Interface Family %R and

- Page 75 and 76:

Variables Variable Mnemonic Descrip

- Page 77 and 78:

3.8.1.7 Spindle Status: %R12.W Vari

- Page 79 and 80:

3.8.1.10 Other Variables Variables

- Page 81 and 82:

3.8.1.13 1050 Servo-Drive Status Wo

- Page 83 and 84:

Variable Mnemonic Description %W3.0

- Page 85 and 86:

3.8.2.4 Negative JOG Commands: %WA.

- Page 87 and 88:

Programme %9999.9 must be structure

- Page 89 and 90:

3.8.2.13 Spindle Controls: %W22.W V

- Page 91 and 92:

- Select spindle b control: COMBRb

- Page 93 and 94:

3.8.2.16 Modes Inhibited: %W30.L Va

- Page 95 and 96:

3.8.2.19 Backward of Forward Moveme

- Page 97 and 98:

3.8.3 Inputs from the Axis Groups V

- Page 99 and 100:

3.8.3.4 Encoded M Function Without

- Page 101 and 102:

Nonmodal functions A nonmodal funct

- Page 103 and 104:

Variables Variable M function Defin

- Page 105 and 106:

3.8.4 Outputs to the Axis Groups Th

- Page 107 and 108:

3.8.5 System Faults and Diagnostic

- Page 109 and 110:

3.8.7 Output Card Write Enable: %W9

- Page 111 and 112:

3.8.10 Physical Organisation of %R

- Page 113 and 114:

3.9.3 Organisation of %S Common Wor

- Page 115 and 116:

Language element Includes Comment V

- Page 117 and 118:

B4_ARR B3_ARR B2_ARR B1_ARR B4_ROT

- Page 119 and 120:

3.11.3 Output to the CNC CHG_ C_ C-

- Page 121 and 122:

VER VER VER VER STOP STOP STOP STOP

- Page 123 and 124:

3.11.4 PLC-CNC Exchange Area - 1050

- Page 125 and 126:

M63 M62 M65 M64 %Rg24.7 %Rg24.6 %Rg

- Page 127 and 128:

Literal Elements of Ladder Language

- Page 129 and 130:

4.1 Notations Used The notations us

- Page 131 and 132:

Literal Elements of Ladder Language

- Page 133 and 134:

4.5.5 Order of Evaluation of the Ex

- Page 135 and 136:

4.5.8 Overflow - Sign Change Litera

- Page 137 and 138:

Programming in Ladder Language 5 Pr

- Page 139 and 140:

5.1 Elements Common to All Types of

- Page 141 and 142: Programming in Ladder Language en-9

- Page 143 and 144: 5.2 Network Sequence 5.2.1 General

- Page 145 and 146: Example 5.2.2.3 Conditional Actions

- Page 147 and 148: Off Timeout «TOF_n» E Q %TQxx.7 T

- Page 149 and 150: Upcounters E C Q %CQxx.7 Threshold

- Page 151 and 152: 5.2.3 Structure of the Action Zone

- Page 153 and 154: Pitfall Related to Scanning Program

- Page 155 and 156: Invalid Network - Branch without Po

- Page 157 and 158: 5.2.7 Programming Hints 5.2.7.1 Opt

- Page 159 and 160: Unoptimised Network Optimised Netwo

- Page 161 and 162: 5.2.7.4 Testing the Bits of a Byte,

- Page 163 and 164: General Purpose Functions 6 General

- Page 165 and 166: General Purpose Functions 6.1 Conve

- Page 167 and 168: General Purpose Functions 6.3 BCD

- Page 169 and 170: General Purpose Functions 6.5 Separ

- Page 171 and 172: General Purpose Functions 6.7 Copy

- Page 173 and 174: General Purpose Functions 6.9 Copy

- Page 175 and 176: Return code If OK Number of charact

- Page 177 and 178: General Purpose Functions 6.14 Simu

- Page 179 and 180: General Purpose Functions 6.17 Sear

- Page 181 and 182: General Purpose Functions 6.20 Jump

- Page 183 and 184: Return code If OK Not significant.

- Page 185 and 186: Return code If OK Value returned by

- Page 187 and 188: Return code If OK Number of charact

- Page 189 and 190: General Purpose Functions 6.31 Copy

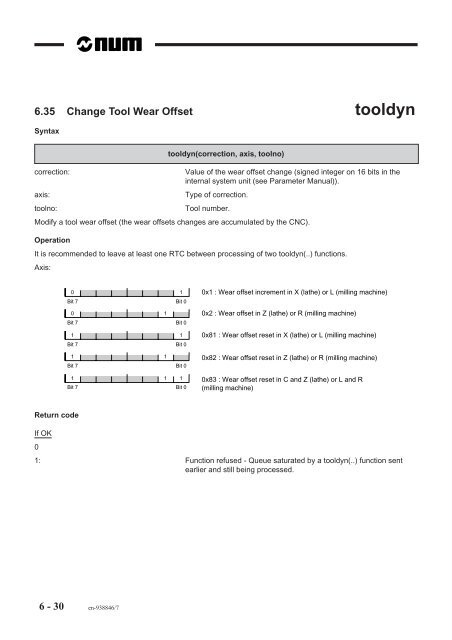

- Page 191: General Purpose Functions 6.34 Swap

- Page 195 and 196: General Purpose Functions 6.38 Init

- Page 197 and 198: Task Management 7 Task Management 7

- Page 199 and 200: 7.1 Introduction Task Management Fo

- Page 201 and 202: Transparent Mode 8 Transparent Mode

- Page 203 and 204: 8.1 Introduction Transparent Mode T

- Page 205 and 206: 8.1.4 Character Codes Used by %R0.W

- Page 207 and 208: 8.2 Functions Assigned to transpare

- Page 209 and 210: Transparent Mode Operation Sends a

- Page 211 and 212: Example 1 Consider the following va

- Page 213 and 214: Transparent Mode 8.2.7 Open a Numer

- Page 215 and 216: Return code Transparent Mode If OK

- Page 217 and 218: Transparent Mode Operation putimage

- Page 219 and 220: en-938846/7 8 - 19 Transparent Mode

- Page 221 and 222: 471 470 89 76 40 0 4 16 COL. 0 A A

- Page 223 and 224: Transparent Mode Description Instru

- Page 225 and 226: 8.3.4 Alphanumeric Characters and I

- Page 227 and 228: Format D (Expanded characters) 0x9B

- Page 229 and 230: Example To position the cursor on L

- Page 231 and 232: Definition of a Reference System Ce

- Page 233 and 234: J: «J» [VALUE] Current Y coordina

- Page 235 and 236: 8.3.5.8 Shift Screen Origin Instruc

- Page 237 and 238: P2 P1 P1 P2 P1 P2 N1 P3 P1 N6 P0 P0

- Page 239 and 240: ! CAUTION Arguments [CLIP], [X] and

- Page 241 and 242: Analogue Inputs/Outputs 9 Analogue

- Page 243 and 244:

9.1 General Analogue Inputs/Outputs

- Page 245 and 246:

Analogue Inputs/Outputs 9.3 Write a

- Page 247 and 248:

Analogue Inputs/Outputs 9.5 Reassig

- Page 249 and 250:

Explicit Read/Write of Input/Output

- Page 251 and 252:

10.1 General Explicit Read/Write of

- Page 253 and 254:

Explicit Read/Write of Input/Output

- Page 255 and 256:

Interrupt Inputs 11 Interrupt Input

- Page 257 and 258:

11.1 General The automatic control

- Page 259 and 260:

11.2 Principle of Line Assignment N

- Page 261 and 262:

Example Filtering on rising edge T1

- Page 263 and 264:

Interrupt Inputs 11.6 Associate a %

- Page 265 and 266:

Serial Lines 12 Serial Lines 12.1 G

- Page 267 and 268:

12.1 General The automatic control

- Page 269 and 270:

Detail of the «format» argument 0

- Page 271 and 272:

PERIPHERAL Transmission to peripher

- Page 273 and 274:

Copy requested No. into buffer Yes

- Page 275 and 276:

Serial Lines 12.6 Control the Seria

- Page 277 and 278:

Serial Lines 12.7.2.3 Xon/Xoff Flow

- Page 279 and 280:

13.1 General Description of the Tim

- Page 281 and 282:

14.1 General Description of the Dat

- Page 283 and 284:

Exchanges by Protocol 15 Exchanges

- Page 285 and 286:

15.1 General Description of Exchang

- Page 287 and 288:

15.1.2 DNC1000 Exchange Mechanism E

- Page 289 and 290:

15.2 Objects Accessible by a UNITE

- Page 291 and 292:

15.2.2 Object Constituents The IU c

- Page 293 and 294:

Exchanges by Protocol Segment Acces

- Page 295 and 296:

Exchanges by Protocol Segment Acces

- Page 297 and 298:

Detailed List of G Functions Presen

- Page 299 and 300:

Example of reading the current prog

- Page 301 and 302:

15.3.3 «DELETE-FILE» Request Used

- Page 303 and 304:

Negative answer ANSWER CODE (1 byte

- Page 305 and 306:

Request format Answer format Positi

- Page 307 and 308:

15.3.8 «READ-BLOCK» Request Used

- Page 309 and 310:

15.3.10 «RESERVE-MEMORY» Request

- Page 311 and 312:

Exchanges by Protocol Transmission

- Page 313 and 314:

Return code If OK Code Report messa

- Page 315 and 316:

TRANSMISSION (PORT 0x30) TRANSMISSI

- Page 317 and 318:

Structure of the Transmission Buffe

- Page 319 and 320:

Structure of the Reception Buffer B

- Page 321 and 322:

Exchanges by Protocol 15.5.4 Settin

- Page 323 and 324:

Programming in C Language 16 Progra

- Page 325 and 326:

16.1 General Programming in C Langu

- Page 327 and 328:

16.4 Programming in C 16.4.1 Concep

- Page 329 and 330:

16.4.3 Exchange Area Programming in

- Page 331 and 332:

16.4.9 Library Functions Programmin

- Page 333 and 334:

16.4.9.2 Using System Functions Exa

- Page 335 and 336:

Programming in C Language Read an I

- Page 337 and 338:

Programming in C Language Initialis

- Page 339 and 340:

Programming in C Language Draw a Ci

- Page 341 and 342:

Programming in C Language Colour an

- Page 343 and 344:

Programming in C Language Read an A

- Page 345 and 346:

Programming in C Language End a Cri

- Page 347 and 348:

Programming in C Language Semaphore

- Page 349 and 350:

Programming in C Language REMARKS I

- Page 351 and 352:

Programming in C Language Write a F

- Page 353 and 354:

Description of a Directory File A d

- Page 355 and 356:

17.1 General The PLC axis programmi

- Page 357 and 358:

18 Programme Debugging 18.1 Program

- Page 359 and 360:

Programme Debugging 18.1 Programme

- Page 361 and 362:

18.2.2 Monitoring CPU Operation Thi

- Page 363 and 364:

Programme Debugging Messages Commen

- Page 365 and 366:

Requirements «PLC OPERATION» menu

- Page 367 and 368:

18.2.3 Monitor and %TS Task Times P

- Page 369 and 370:

18.2.4 File Management This functio

- Page 371 and 372:

18.2.4.2 Application Directory This

- Page 373 and 374:

18.2.5 Input/Output Configuration T

- Page 375 and 376:

Example Identification of rack 0 an

- Page 377 and 378:

18.2.6.1 Software Backup Actions Se

- Page 379 and 380:

Select the module to be animated us

- Page 381 and 382:

Load a new Ladder module Press «F2

- Page 383 and 384:

Write a Variable Press «F10». ☞

- Page 385 and 386:

19.1 List of Hardware Errors ERR_BU

- Page 387 and 388:

Lists of Functions A Lists of Funct

- Page 389 and 390:

A.1 List by Themes A.1.1 General Pu

- Page 391 and 392:

A.1.6 Interrupt Input Management Li

- Page 393 and 394:

Lists of Functions Function Descrip

- Page 395 and 396:

Symbols %I Organisation 3-15 %INI 2

- Page 397 and 398:

L Label 4-3 Ladder module structure