1938 LaSalle Production - GM Heritage Center

1938 LaSalle Production - GM Heritage Center

1938 LaSalle Production - GM Heritage Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cadillac-LaSaile Preliminary Service Information 17<br />

to which the rods from the control shafts are<br />

attached; while on the inner end a shoe on an inner<br />

lever contacts the high and intermediate<br />

shifter disc, and the shoe on the other lever shifts<br />

the low and reverse sliding gear.<br />

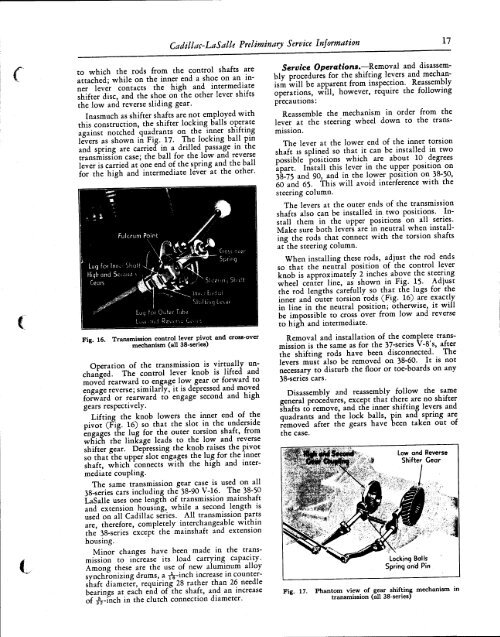

Inasmuch as shifter shafts are not employed with<br />

this construction, the shifter locking balls operate<br />

against notched quadrants on the inner shifting<br />

levers as shown in Fig. 17. The locking ball pin<br />

and spring are carried in a drilled passage in the<br />

transmission case; the ball for the low and reverse<br />

lever is carried at one end of the spring and the ball<br />

for the high and intermediate lever at the other.<br />

Fulcrum Point<br />

Lug for IniK- Shaft 4 • .-.V^<br />

Hi,hand 5" d l J^V,.w<br />

Gears {^V"^- " 1 *<br />

Luy for Outer Tuba<br />

Low .11)--1 Re^'r^ C<br />

Cro^s-over<br />

Spring<br />

SU:enn„, Sli Jft<br />

• hiftun] L«rwi<br />

Fig. 16. Transmission control lever pivot and cross-over<br />

mechanism (all 38-series)<br />

Operation of the transmission is virtually unchanged.<br />

The control lever knob is lifted and<br />

moved rearward to engage low gear or forward to<br />

engage reverse; similarly, it is depressed and moved<br />

forward or rearward to engage second and high<br />

gears respectively.<br />

Lifting the knob lowers the inner end of the<br />

pivot (Fig. 16) so that the slot in the underside<br />

engages the lug for the outer torsion shaft, from<br />

which the linkage leads to the low and reverse<br />

shifter gear. Depressing the knob raises the pivot<br />

so that the upper slot engages the lug for the inner<br />

shaft, which connects with the high and intermediate<br />

coupling.<br />

The same transmission gear case is used on all<br />

38-series cars including the 38-90 V-16. The 38-50<br />

<strong>LaSalle</strong> uses one length of transmission mainshaft<br />

and extension housing, while a second length is<br />

used on all Cadillac series. AH transmission parts<br />

are, therefore, completely interchangeable within<br />

the 38-series except the mainshaft and extension<br />

housing.<br />

Minor changes have been made in the transmission<br />

to increase its load carrying capacity.<br />

Among these are the use of new aluminum alloy<br />

synchronizing drums, a j^-inch increase in countershaft<br />

diameter, requiring 28 rather than 26 needle<br />

bearings at each end of the shaft, and an increase<br />

of ^-inch in the clutch connection diameter.<br />

Service Operations.—Removal and disassembly<br />

procedures for the shifting levers and mechanism<br />

will be apparent from inspection. Reassembly<br />

operations, will, however, require the following<br />

precautions:<br />

Reassemble the mechanism in order from the<br />

lever at the steering wheel down to the transmission.<br />

The lever at the lower end of the inner torsion<br />

shaft is splined so that it can be installed in two<br />

possible positions which are about 10 degrees<br />

apart. Install this lever in the upper position on<br />

38-75 and 90, and in the lower position on 38-50,<br />

60 and 65. This will avoid interference with the<br />

steering column.<br />

The levers at the outer ends of the transmission<br />

shafts also can be installed in two positions. Install<br />

them in the upper positions on all series.<br />

Make sure both levers are in neutral when installing<br />

the rods that connect with the torsion shafts<br />

at the steering column.<br />

When installing these rods, adjust the rod ends<br />

so that the neutral position of the control lever<br />

knob is approximately 2 inches above the steering<br />

wheel center line, as shown in Fig. 15. Adjust<br />

the rod lengths carefully so that the lugs for the<br />

inner and outer torsion rods (Fig. 16) are exactly<br />

in line in the neutral position; otherwise, it will<br />

be impossible to cross over from low and reverse<br />

to high and intermediate.<br />

Removal and installation of the complete transmission<br />

is the same as for the 37-series V-8's, after<br />

the shifting rods have been disconnected. The<br />

levers must also be removed on 38-60. It is not<br />

necessary to disturb the floor or toe-boards on any<br />

38-series cars.<br />

Disassembly and reassembly follow the same<br />

general procedures, except that there are no shifter<br />

shafts to remove, and the inner shifting levers and<br />

quadrants and the lock balls, pin and spring arc<br />

removed after the gears have been taken out of<br />

the case.<br />

Fig. 17.<br />

Low and Reverse<br />

Shifter Gear<br />

Locking Balls<br />

Spring and Pin<br />

Phantom view of gear shifting mechanism in<br />

transmission (all 38-series)