Annona Species Monograph.pdf - Crops for the Future

Annona Species Monograph.pdf - Crops for the Future

Annona Species Monograph.pdf - Crops for the Future

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

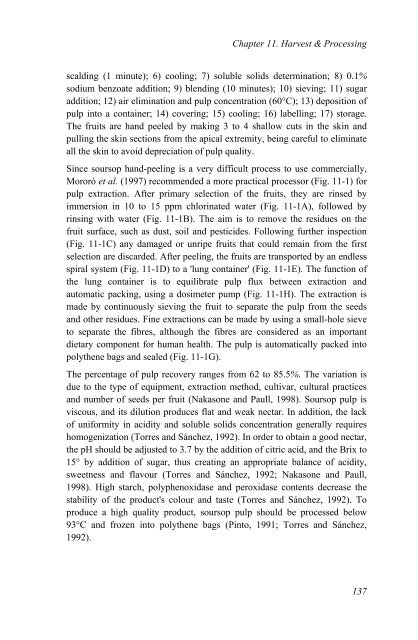

Chapter 11. Harvest & Processing<br />

scalding (1 minute); 6) cooling; 7) soluble solids determination; 8) 0.1%<br />

sodium benzoate addition; 9) blending (10 minutes); 10) sieving; 11) sugar<br />

addition; 12) air elimination and pulp concentration (60°C); 13) deposition of<br />

pulp into a container; 14) covering; 15) cooling; 16) labelling; 17) storage.<br />

The fruits are hand peeled by making 3 to 4 shallow cuts in <strong>the</strong> skin and<br />

pulling <strong>the</strong> skin sections from <strong>the</strong> apical extremity, being careful to eliminate<br />

all <strong>the</strong> skin to avoid depreciation of pulp quality.<br />

Since soursop hand-peeling is a very difficult process to use commercially,<br />

Mororó et al. (1997) recommended a more practical processor (Fig. 11-1) <strong>for</strong><br />

pulp extraction. After primary selection of <strong>the</strong> fruits, <strong>the</strong>y are rinsed by<br />

immersion in 10 to 15 ppm chlorinated water (Fig. 11-1A), followed by<br />

rinsing with water (Fig. 11-1B). The aim is to remove <strong>the</strong> residues on <strong>the</strong><br />

fruit surface, such as dust, soil and pesticides. Following fur<strong>the</strong>r inspection<br />

(Fig. 11-1C) any damaged or unripe fruits that could remain from <strong>the</strong> first<br />

selection are discarded. After peeling, <strong>the</strong> fruits are transported by an endless<br />

spiral system (Fig. 11-1D) to a 'lung container' (Fig. 11-1E). The function of<br />

<strong>the</strong> lung container is to equilibrate pulp flux between extraction and<br />

automatic packing, using a dosimeter pump (Fig. 11-1H). The extraction is<br />

made by continuously sieving <strong>the</strong> fruit to separate <strong>the</strong> pulp from <strong>the</strong> seeds<br />

and o<strong>the</strong>r residues. Fine extractions can be made by using a small-hole sieve<br />

to separate <strong>the</strong> fibres, although <strong>the</strong> fibres are considered as an important<br />

dietary component <strong>for</strong> human health. The pulp is automatically packed into<br />

poly<strong>the</strong>ne bags and sealed (Fig. 11-1G).<br />

The percentage of pulp recovery ranges from 62 to 85.5%. The variation is<br />

due to <strong>the</strong> type of equipment, extraction method, cultivar, cultural practices<br />

and number of seeds per fruit (Nakasone and Paull, 1998). Soursop pulp is<br />

viscous, and its dilution produces flat and weak nectar. In addition, <strong>the</strong> lack<br />

of uni<strong>for</strong>mity in acidity and soluble solids concentration generally requires<br />

homogenization (Torres and Sánchez, 1992). In order to obtain a good nectar,<br />

<strong>the</strong> pH should be adjusted to 3.7 by <strong>the</strong> addition of citric acid, and <strong>the</strong> Brix to<br />

15° by addition of sugar, thus creating an appropriate balance of acidity,<br />

sweetness and flavour (Torres and Sánchez, 1992; Nakasone and Paull,<br />

1998). High starch, polyphenoxidase and peroxidase contents decrease <strong>the</strong><br />

stability of <strong>the</strong> product's colour and taste (Torres and Sánchez, 1992). To<br />

produce a high quality product, soursop pulp should be processed below<br />

93°C and frozen into poly<strong>the</strong>ne bags (Pinto, 1991; Torres and Sánchez,<br />

1992).<br />

137