Photonic crystals in biology - NanoTR-VI

Photonic crystals in biology - NanoTR-VI

Photonic crystals in biology - NanoTR-VI

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

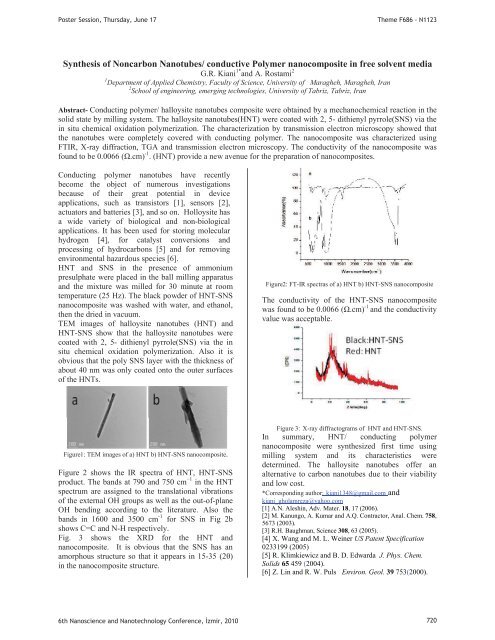

Poster Session, Thursday, June 17Theme F686 - N1123Synthesis of Noncarbon Nanotubes/ conductive Polymer nanocomposite <strong>in</strong> free solvent mediaG.R. Kiani 1* and A. Rostami 21 Department of Applied Chemistry, Faculty of Science, University of Maragheh, Maragheh, Iran2 School of eng<strong>in</strong>eer<strong>in</strong>g, emerg<strong>in</strong>g technologies, University of Tabriz, Tabriz, IranAbstract- Conduct<strong>in</strong>g polymer/ halloysite nanotubes composite were obta<strong>in</strong>ed by a mechanochemical reaction <strong>in</strong> thesolid state by mill<strong>in</strong>g system. The halloysite nanotubes(HNT) were coated with 2, 5- dithienyl pyrrole(SNS) via the<strong>in</strong> situ chemical oxidation polymerization. The characterization by transmission electron microscopy showed thatthe nanotubes were completely covered with conduct<strong>in</strong>g polymer. The nanocomposite was characterized us<strong>in</strong>gFTIR, X-ray diffraction, TGA and transmission electron microscopy. The conductivity of the nanocomposite wasfound to be 0.0066 (cm) -1 . (HNT) provide a new avenue for the preparation of nanocomposites.Conduct<strong>in</strong>g polymer nanotubes have recentlybecome the object of numerous <strong>in</strong>vestigationsbecause of their great potential <strong>in</strong> deviceapplications, such as transistors [1], sensors [2],actuators and batteries [3], and so on. Holloysite hasa wide variety of biological and non-biologicalapplications. It has been used for stor<strong>in</strong>g molecularhydrogen [4], for catalyst conversions andprocess<strong>in</strong>g of hydrocarbons [5] and for remov<strong>in</strong>genvironmental hazardous species [6].HNT and SNS <strong>in</strong> the presence of ammoniumpresulphate were placed <strong>in</strong> the ball mill<strong>in</strong>g apparatusand the mixture was milled for 30 m<strong>in</strong>ute at roomtemperature (25 Hz). The black powder of HNT-SNSnanocomposite was washed with water, and ethanol,then the dried <strong>in</strong> vacuum.TEM images of halloysite nanotubes (HNT) andHNT-SNS show that the halloysite nanotubes werecoated with 2, 5- dithienyl pyrrole(SNS) via the <strong>in</strong>situ chemical oxidation polymerization. Also it isobvious that the poly SNS layer with the thickness ofabout 40 nm was only coated onto the outer surfacesof the HNTs.Figure2: FT-IR spectras of a) HNT b) HNT-SNS nanocompositeThe conductivity of the HNT-SNS nanocompositewas found to be 0.0066 (cm) -1 and the conductivityvalue was acceptable.Figure1: TEM images of a) HNT b) HNT-SNS nanocomposite.Figure 2 shows the IR spectra of HNT, HNT-SNSproduct. The bands at 790 and 750 cm 1 <strong>in</strong> the HNTspectrum are assigned to the translational vibrationsof the external OH groups as well as the out-of-planeOH bend<strong>in</strong>g accord<strong>in</strong>g to the literature. Also thebands <strong>in</strong> 1600 and 3500 cm -1 for SNS <strong>in</strong> Fig 2bshows C=C and N-H respectively.Fig. 3 shows the XRD for the HNT andnanocomposite. It is obvious that the SNS has anamorphous structure so that it appears <strong>in</strong> 15-35 (2)<strong>in</strong> the nanocomposite structure.Figure 3: X-ray diffractograms of HNT and HNT-SNS.In summary, HNT/ conduct<strong>in</strong>g polymernanocomposite were synthesized first time us<strong>in</strong>gmill<strong>in</strong>g system and its characteristics weredeterm<strong>in</strong>ed. The halloysite nanotubes offer analternative to carbon nanotubes due to their viabilityand low cost.*Correspond<strong>in</strong>g author: kiani1348@gmail.com andkiani_gholamreza@yahoo.com[1] A.N. Alesh<strong>in</strong>, Adv. Mater. 18, 17 (2006).[2] M. Kanungo, A. Kumar and A.Q. Contractor, Anal. Chem. 758,5673 (2003).[3] R.H. Baughman, Science 308, 63 (2005).[4] X. Wang and M. L. We<strong>in</strong>er US Patent Specification0233199 (2005)[5] R. Klimkiewicz and B. D. Edwarda J. Phys. Chem.Solids 65 459 (2004).[6] Z. L<strong>in</strong> and R. W. Puls Environ. Geol. 39 753(2000).6th Nanoscience and Nanotechnology Conference, zmir, 2010 720