Photonic crystals in biology - NanoTR-VI

Photonic crystals in biology - NanoTR-VI

Photonic crystals in biology - NanoTR-VI

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

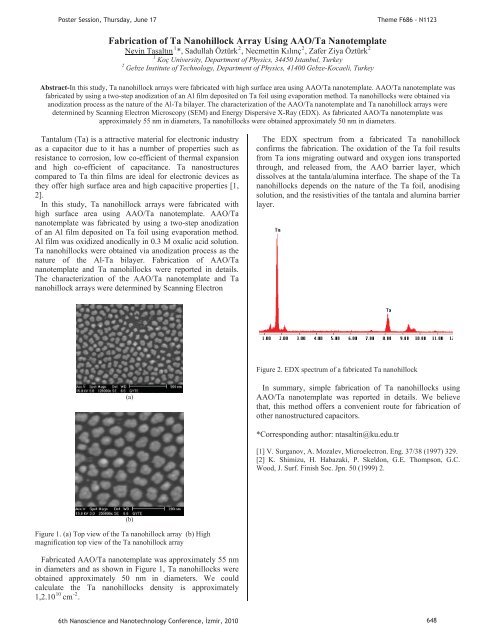

PPPoster Session, Thursday, June 17Theme F686 - N1123Fabrication of Ta Nanohillock Array Us<strong>in</strong>g AAO/Ta Nanotemplate1222UNev<strong>in</strong> TaaltnUP P*, Sadullah ÖztürkP P, Necmett<strong>in</strong> KlnçP P, Zafer Ziya ÖztürkP21PKoç University, Department of Physics, 34450 Istanbul, TurkeyPGebze Institute of Technology, Department of Physics, 41400 Gebze-Kocaeli, TurkeyAbstract-In this study, Ta nanohillock arrays were fabricated with high surface area us<strong>in</strong>g AAO/Ta nanotemplate. AAO/Ta nanotemplate wasfabricated by us<strong>in</strong>g a two-step anodization of an Al film deposited on Ta foil us<strong>in</strong>g evaporation method. Ta nanohillocks were obta<strong>in</strong>ed viaanodization process as the nature of the Al-Ta bilayer. The characterization of the AAO/Ta nanotemplate and Ta nanohillock arrays weredeterm<strong>in</strong>ed by Scann<strong>in</strong>g Electron Microscopy (SEM) and Energy Dispersive X-Ray (EDX). As fabricated AAO/Ta nanotemplate wasapproximately 55 nm <strong>in</strong> diameters, Ta nanohillocks were obta<strong>in</strong>ed approximately 50 nm <strong>in</strong> diameters.Tantalum (Ta) is a attractive material for electronic <strong>in</strong>dustryas a capacitor due to it has a number of properties such asresistance to corrosion, low co-efficient of thermal expansionand high co-efficient of capacitance. Ta nanostructurescompared to Ta th<strong>in</strong> films are ideal for electronic devices asthey offer high surface area and high capacitive properties [1,2].In this study, Ta nanohillock arrays were fabricated withhigh surface area us<strong>in</strong>g AAO/Ta nanotemplate. AAO/Tananotemplate was fabricated by us<strong>in</strong>g a two-step anodizationof an Al film deposited on Ta foil us<strong>in</strong>g evaporation method.Al film was oxidized anodically <strong>in</strong> 0.3 M oxalic acid solution.Ta nanohillocks were obta<strong>in</strong>ed via anodization process as thenature of the Al-Ta bilayer. Fabrication of AAO/Tananotemplate and Ta nanohillocks were reported <strong>in</strong> details.The characterization of the AAO/Ta nanotemplate and Tananohillock arrays were determ<strong>in</strong>ed by Scann<strong>in</strong>g ElectronThe EDX spectrum from a fabricated Ta nanohillockconfirms the fabrication. The oxidation of the Ta foil resultsfrom Ta ions migrat<strong>in</strong>g outward and oxygen ions transportedthrough, and released from, the AAO barrier layer, whichdissolves at the tantala/alum<strong>in</strong>a <strong>in</strong>terface. The shape of the Tananohillocks depends on the nature of the Ta foil, anodis<strong>in</strong>gsolution, and the resistivities of the tantala and alum<strong>in</strong>a barrierlayer.Figure 2. EDX spectrum of a fabricated Ta nanohillock(a)In summary, simple fabrication of Ta nanohillocks us<strong>in</strong>gAAO/Ta nanotemplate was reported <strong>in</strong> details. We believethat, this method offers a convenient route for fabrication ofother nanostructured capacitors.*Correspond<strong>in</strong>g author: ntasalt<strong>in</strong>@ku.edu.tr[1] V. Surganov, A. Mozalev, Microelectron. Eng. 37/38 (1997) 329.[2] K. Shimizu, H. Habazaki, P. Skeldon, G.E. Thompson, G.C.Wood, J. Surf. F<strong>in</strong>ish Soc. Jpn. 50 (1999) 2.Figure 1. (a) Top view of the Ta nanohillock array (b) Highmagnification top view of the Ta nanohillock array(b)Fabricated AAO/Ta nanotemplate was approximately 55 nm<strong>in</strong> diameters and as shown <strong>in</strong> Figure 1, Ta nanohillocks wereobta<strong>in</strong>ed approximately 50 nm <strong>in</strong> diameters. We couldcalculate the Ta nanohillocks density is approximately10 -21,2.10PPcmPP.6th Nanoscience and Nanotechnology Conference, zmir, 2010 648