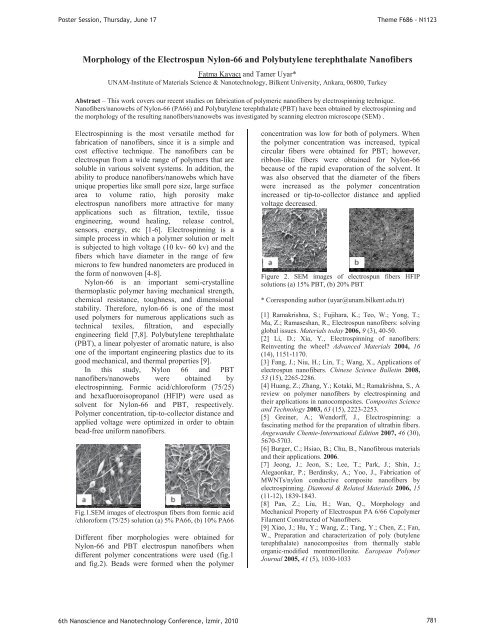

Poster Session, Thursday, June 17Theme F686 - N1123Morphology of the Electrospun Nylon-66 and Polybutylene terephthalate NanofibersFatma Kayacı and Tamer Uyar*UNAM-Institute of Materials Science & Nanotechnology, Bilkent University, Ankara, 06800, TurkeyAbstract – This work covers our recent studies on fabrication of polymeric nanofibers by electrosp<strong>in</strong>n<strong>in</strong>g technique.Nanofibers/nanowebs of Nylon-66 (PA66) and Polybutylene terephthalate (PBT) have been obta<strong>in</strong>ed by electrosp<strong>in</strong>n<strong>in</strong>g andthe morphology of the result<strong>in</strong>g nanofibers/nanowebs was <strong>in</strong>vestigated by scann<strong>in</strong>g electron microscope (SEM) .Electrosp<strong>in</strong>n<strong>in</strong>g is the most versatile method forfabrication of nanofibers, s<strong>in</strong>ce it is a simple andcost effective technique. The nanofibers can beelectrospun from a wide range of polymers that aresoluble <strong>in</strong> various solvent systems. In addition, theability to produce nanofibers/nanowebs which haveunique properties like small pore size, large surfacearea to volume ratio, high porosity makeelectrospun nanofibers more attractive for manyapplications such as filtration, textile, tissueeng<strong>in</strong>eer<strong>in</strong>g, wound heal<strong>in</strong>g, release control,sensors, energy, etc [1-6]. Electrosp<strong>in</strong>n<strong>in</strong>g is asimple process <strong>in</strong> which a polymer solution or meltis subjected to high voltage (10 kv- 60 kv) and thefibers which have diameter <strong>in</strong> the range of fewmicrons to few hundred nanometers are produced <strong>in</strong>the form of nonwoven [4-8].Nylon-66 is an important semi-crystall<strong>in</strong>ethermoplastic polymer hav<strong>in</strong>g mechanical strength,chemical resistance, toughness, and dimensionalstability. Therefore, nylon-66 is one of the mostused polymers for numerous applications such astechnical texiles, filtration, and especiallyeng<strong>in</strong>eer<strong>in</strong>g field [7,8]. Polybutylene terephthalate(PBT), a l<strong>in</strong>ear polyester of aromatic nature, is alsoone of the important eng<strong>in</strong>eer<strong>in</strong>g plastics due to itsgood mechanical, and thermal properties [9].In this study, Nylon 66 and PBTnanofibers/nanowebs were obta<strong>in</strong>ed byelectrosp<strong>in</strong>n<strong>in</strong>g. Formic acid/chloroform (75/25)and hexafluoroisopropanol (HFIP) were used assolvent for Nylon-66 and PBT, respectively.Polymer concentration, tip-to-collector distance andapplied voltage were optimized <strong>in</strong> order to obta<strong>in</strong>bead-free uniform nanofibers.Fig.1.SEM images of electrospun fibers from formic acid/chloroform (75/25) solution (a) 5% PA66, (b) 10% PA66Different fiber morphologies were obta<strong>in</strong>ed forNylon-66 and PBT electrospun nanofibers whendifferent polymer concentrations were used (fig.1and fig.2). Beads were formed when the polymerconcentration was low for both of polymers. Whenthe polymer concentration was <strong>in</strong>creased, typicalcircular fibers were obta<strong>in</strong>ed for PBT; however,ribbon-like fibers were obta<strong>in</strong>ed for Nylon-66because of the rapid evaporation of the solvent. Itwas also observed that the diameter of the fiberswere <strong>in</strong>creased as the polymer concentration<strong>in</strong>creased or tip-to-collector distance and appliedvoltage decreased.Figure 2. SEM images of electrospun fibers HFIPsolutions (a) 15% PBT, (b) 20% PBT* Correspond<strong>in</strong>g author (uyar@unam.bilkent.edu.tr)[1] Ramakrishna, S.; Fujihara, K.; Teo, W.; Yong, T.;Ma, Z.; Ramaseshan, R., Electrospun nanofibers: solv<strong>in</strong>gglobal issues. Materials today 2006, 9 (3), 40-50.[2] Li, D.; Xia, Y., Electrosp<strong>in</strong>n<strong>in</strong>g of nanofibers:Re<strong>in</strong>vent<strong>in</strong>g the wheel? Advanced Materials 2004, 16(14), 1151-1170.[3] Fang, J.; Niu, H.; L<strong>in</strong>, T.; Wang, X., Applications ofelectrospun nanofibers. Ch<strong>in</strong>ese Science Bullet<strong>in</strong> 2008,53 (15), 2265-2286.[4] Huang, Z.; Zhang, Y.; Kotaki, M.; Ramakrishna, S., Areview on polymer nanofibers by electrosp<strong>in</strong>n<strong>in</strong>g andtheir applications <strong>in</strong> nanocomposites. Composites Scienceand Technology 2003, 63 (15), 2223-2253.[5] Gre<strong>in</strong>er, A.; Wendorff, J., Electrosp<strong>in</strong>n<strong>in</strong>g: afasc<strong>in</strong>at<strong>in</strong>g method for the preparation of ultrath<strong>in</strong> fibers.Angewandte Chemie-International Edition 2007, 46 (30),5670-5703.[6] Burger, C.; Hsiao, B.; Chu, B., Nanofibrous materialsand their applications. 2006.[7] Jeong, J.; Jeon, S.; Lee, T.; Park, J.; Sh<strong>in</strong>, J.;Alegaonkar, P.; Berd<strong>in</strong>sky, A.; Yoo, J., Fabrication ofMWNTs/nylon conductive composite nanofibers byelectrosp<strong>in</strong>n<strong>in</strong>g. Diamond & Related Materials 2006, 15(11-12), 1839-1843.[8] Pan, Z.; Liu, H.; Wan, Q., Morphology andMechanical Property of Electrospun PA 6/66 CopolymerFilament Constructed of Nanofibers.[9] Xiao, J.; Hu, Y.; Wang, Z.; Tang, Y.; Chen, Z.; Fan,W., Preparation and characterization of poly (butyleneterephthalate) nanocomposites from thermally stableorganic-modified montmorillonite. European PolymerJournal 2005, 41 (5), 1030-10336th Nanoscience and Nanotechnology Conference, zmir, 2010 781

Poster Session, Thursday, June 17Theme F686 - N1123Functional Electrospun Nanofibers from Biocompatible PolymersAslı Çelebioğlu and Tamer Uyar*UNAM-Institute of Materials Science & Nanotechnology, Bilkent University, Ankara, 06800, TurkeyAbstract – In this study, we have electrospun nanofibers/nanowebs from polymers which are known for theirbiocompatibility. We produced uniform nanofibers/nanowebs from poly(v<strong>in</strong>yl alcohol) (PVA),poly(caprolactone) (PCL), poly(ethylene oxide) (PEO), cellulose acetate (CA) and polyv<strong>in</strong>ylprolidone (PVP).Electrosp<strong>in</strong>n<strong>in</strong>g is the most versatilemethod for produc<strong>in</strong>g ultraf<strong>in</strong>e fibers which havediameter at micro/nano size. Many different k<strong>in</strong>dsof natural and synthetic polymers can be used toobta<strong>in</strong> nanofiber/nanoweb structures by us<strong>in</strong>g thistechnique. Electrosp<strong>in</strong>n<strong>in</strong>g method bases onapply<strong>in</strong>g high voltage to solutions/melts ofpolymers. The diamater, uniformity andmorphology of fibers are controlled by processparameters such as; applied voltage, feed rate, tip tocollector distance and the polymer/solvent typesthat is used. The unique properties like largesurface area to volume ratio, small pore size withhigh porosity and design flexibility makeelectrospun nanofibers more attractive for manyapplications such as filtration, biomedical, energy,packag<strong>in</strong>g, functional textiles, etc [1-4].Biomedical field is one of the mostimportant application areas for nanofibers/nanowebs s<strong>in</strong>ce they are applicable <strong>in</strong> tissueeng<strong>in</strong>eer<strong>in</strong>g, drug release and wound heal<strong>in</strong>g, etc.The size similarity between nano-sized materialsand biological systems and hav<strong>in</strong>g high porositymake these nanofibers /nanowebs suitable andeffective for biomedical applications [5, 6].In this work; poly(v<strong>in</strong>yl alcohol) (PVA),poly(caprolactone) (PCL), poly(ethylene oxide)(PEO), cellulose acetate (CA) and polyv<strong>in</strong>ylprolidone (PVP) were electrospun for produc<strong>in</strong>gnanofibrous materials which have possibilities to beused <strong>in</strong> biomedical area such as medical textiles,scaffolds for tissue regeneration, wound dress<strong>in</strong>g,drug delivery systems, etc. In order to obta<strong>in</strong>homogenous, bead-free nanofibers/nanowebs, theoptimization of the electrosp<strong>in</strong>n<strong>in</strong>g process hasbeen achieved by vary<strong>in</strong>g polymer concentrationsand the process parameters like applied voltage,feed rate, tip-to-collector distance, etc. Themorphology of produced nanofibers was exam<strong>in</strong>edby us<strong>in</strong>g scann<strong>in</strong>g electron microscope (SEM).The effect of polymer concentration on themorphology of electrospun nanofibers is shown <strong>in</strong>fig. 1. As seen from SEM images, at low polymerconcentrations beaded fiber structures were formedbut at higher polymer concentrations uniformnanofibers were obta<strong>in</strong>ed. Moreover, we observedthat tip-to- collector distance and applied voltagehave also effect on the morphology of the result<strong>in</strong>gfibers.a) b)c) d)e) f)Figure1. SEM images of electrospun (a) 8% (b) 12% CA,(c) %10 (d) %15 (PVP), (e) %3 (f) %4 PEO nanofibers* Correspond<strong>in</strong>g author (uyar@unam.bilkent.edu.tr)1. Reneker, D.H. and A.L. Yar<strong>in</strong>, Electrosp<strong>in</strong>n<strong>in</strong>gjets and polymer nanofibers. Polymer, 2008.49(10): p. 2387-2425.2. Teo, W. and S. Ramakrishna, A review onelectrosp<strong>in</strong>n<strong>in</strong>g design and nanofibreassemblies. Nanotechnology, 2006. 17: p. R89-R106.3. Li, D. and Y. Xia, Electrosp<strong>in</strong>n<strong>in</strong>g ofnanofibers: re<strong>in</strong>vent<strong>in</strong>g the wheel? AdvancedMaterials, 2004. 16(14): p. 1151-1170.4. Huang, Z.-M., et al., A review on polymernanofibers by electrosp<strong>in</strong>n<strong>in</strong>g and theirapplications <strong>in</strong> nanocomposites. CompositesScience and Technology, 2003. 63(15): p.2223-2253.5. Gre<strong>in</strong>er, A. and J. Wendorff, Electrosp<strong>in</strong>n<strong>in</strong>g: afasc<strong>in</strong>at<strong>in</strong>g method for the preparation ofultrath<strong>in</strong> fibers. Angewandte Chemie-International Edition, 2007. 46(30): p. 5670-5703.6. Ramakrishna, S., et al., Electrospun nanofibers:solv<strong>in</strong>g global issues. Materials Today, 2006.9(3): p. 40-50.6th Nanoscience and Nanotechnology Conference, zmir, 2010 782

- Page 1:

Poster Presentations3rd Day17 June

- Page 4 and 5:

Determination of Dielectric Anisotr

- Page 7 and 8:

Poster Session, Thursday, June 17Th

- Page 9 and 10:

PP mPP vs.P =P,PP (1)P andPoster Se

- Page 11 and 12:

PP mPP vs.P =P,PP (1)P andPoster Se

- Page 13 and 14:

PP andPoster Session, Thursday, Jun

- Page 15 and 16:

Poster Session, Thursday, June 17Th

- Page 17 and 18:

PP and770 772 774 776 778 780 782 7

- Page 19 and 20:

Poster Session, Thursday, June 17Th

- Page 21 and 22:

Poster Session, Thursday, June 17Th

- Page 23 and 24:

P25,Poster Session, Thursday, June

- Page 25 and 26:

PP TOBBPoster Session, Thursday, Ju

- Page 27 and 28:

PisPPisisisP,PisPoster Session, Thu

- Page 29 and 30:

U NeslihanPPPPoster Session, Thursd

- Page 31 and 32:

Poster Session, Thursday, June 17Th

- Page 33 and 34:

PPPoster Session, Thursday, June 17

- Page 35 and 36:

PPoster Session, Thursday, June 17T

- Page 37 and 38:

P onP viaPP wereP upPoster Session,

- Page 39 and 40:

P ·cm.PVPPPsPPPPP andPoster Sessio

- Page 41 and 42:

Poster Session, Thursday, June 17Th

- Page 43 and 44:

PPoster Session, Thursday, June 17T

- Page 45 and 46:

PPoster Session, Thursday, June 17T

- Page 47 and 48:

Poster Session, Thursday, June 17Th

- Page 49 and 50:

PErkanPoster Session, Thursday, Jun

- Page 51 and 52:

Poster Session, Thursday, June 17Th

- Page 53 and 54:

Poster Session, Thursday, June 17Th

- Page 55 and 56:

PPPP andPoster Session, Thursday, J

- Page 57 and 58:

Poster Session, Thursday, June 17Th

- Page 59 and 60:

Poster Session, Thursday, June 17Th

- Page 61 and 62:

T PeptideTPP,PP,PP andTT2429TTTTTT

- Page 63 and 64:

Poster Session, Thursday, June 17Th

- Page 65 and 66:

PPoster Session, Thursday, June 17T

- Page 67 and 68:

Poster Session, Thursday, June 17Th

- Page 69 and 70:

PPPoster Session, Thursday, June 17

- Page 71 and 72:

Poster Session, Thursday, June 17Th

- Page 73 and 74:

Poster Session, Thursday, June 17Th

- Page 75 and 76:

PT AdditionalT ThePoster Session, T

- Page 77 and 78:

Poster Session, Thursday, June 17Th

- Page 79 and 80:

Poster Session, Thursday, June 17Th

- Page 81 and 82:

Poster Session, Thursday, June 17Th

- Page 83 and 84:

PPoster Session, Thursday, June 17T

- Page 85 and 86:

Poster Session, Thursday, June 17Th

- Page 87 and 88:

PPPoster Session, Thursday, June 17

- Page 89 and 90:

Poster Session, Thursday, June 17Hu

- Page 91 and 92:

Poster Session, Thursday, June 17Th

- Page 93 and 94:

PPPPPPoster Session, Thursday, June

- Page 95 and 96:

Poster Session, Thursday, June 17Th

- Page 97 and 98:

Poster Session, Thursday, June 17Th

- Page 99 and 100:

Poster Session, Thursday, June 17Th

- Page 101 and 102:

PPoster Session, Thursday, June 17T

- Page 103 and 104:

Poster Session, Thursday, June 17Th

- Page 105 and 106:

PPPPPPPoster Session, Thursday, Jun

- Page 107 and 108:

Poster Session, Thursday, June 17Th

- Page 109 and 110:

PPPR2R PIN(80)PPgPP OzlemPPoster Se

- Page 111 and 112:

Poster Session, Thursday, June 17Th

- Page 113 and 114:

Poster Session, Thursday, June 17Th

- Page 115 and 116:

P onPP toP coordinatedPPoster Sessi

- Page 117 and 118:

PPPPP,PP,P(PR RmPoster Session, Thu

- Page 119 and 120:

Poster Session, Thursday, June 17Th

- Page 121 and 122:

Poster Session, Thursday, June 17Th

- Page 123 and 124: PP InstitutePP DepartmentPoster Ses

- Page 125 and 126: andPCPPoster Session, Thursday, Jun

- Page 127 and 128: PP scatteringPYusufPP Corresponding

- Page 129 and 130: PP toPoster Session, Thursday, June

- Page 131 and 132: PP andPoster Session, Thursday, Jun

- Page 133 and 134: PPPPoster Session, Thursday, June 1

- Page 135 and 136: PPoster Session, Thursday, June 17T

- Page 137 and 138: PPP andP (.cm).Poster Session, Thur

- Page 139 and 140: PP tiltP andP editionPoster Session

- Page 141 and 142: PP andPPoster Session, Thursday, Ju

- Page 143 and 144: Poster Session, Thursday, June 17Th

- Page 145 and 146: PP forP forP edit.PPoster Session,

- Page 147 and 148: Poster Session, Thursday, June 17Th

- Page 149 and 150: Poster Session, Thursday, June 17Th

- Page 151 and 152: PP ionicPP ,PPoster Session, Thursd

- Page 153 and 154: PP lightPoster Session, Thursday, J

- Page 155 and 156: Poster Session, Thursday, June 17Th

- Page 157 and 158: PPoster Session, Thursday, June 17T

- Page 159 and 160: Poster Session, Thursday, June 17Th

- Page 161 and 162: PandPoster Session, Thursday, June

- Page 163 and 164: Poster Session, Thursday, June 17 T

- Page 165 and 166: PPPoster Session, Thursday, June 17

- Page 167 and 168: PPoster Session, Thursday, June 17T

- Page 169 and 170: PPoster Session, Thursday, June 17T

- Page 171 and 172: PPoster Session, Thursday, June 17T

- Page 173: PP DepartmentNanoscienceTPPoster Se

- Page 177 and 178: Poster Session, Thursday, June 17Th

- Page 179 and 180: PPPoster Session, Thursday, June 17

- Page 181 and 182: PPPPPoster Session, Thursday, June

- Page 183 and 184: PPPPoster Session, Thursday, June 1

- Page 185 and 186: PPoster Session, Thursday, June 17T

- Page 187 and 188: PPoster Session, Thursday, June 17T

- Page 189 and 190: PPoster Session, Thursday, June 17T

- Page 191 and 192: Poster Session, Thursday, June 17Th

- Page 193 and 194: Poster Session, Thursday, June 17Th

- Page 195 and 196: 0T0T0T0T AsPPPP werePoster Session,

- Page 197 and 198: PPoster Session, Thursday, June 17T

- Page 199 and 200: PPPPPoster Session, Thursday, June

- Page 201 and 202: PPoster Session, Thursday, June 17T

- Page 203 and 204: PPoster Session, Thursday, June 17T

- Page 205 and 206: Poster Session, Thursday, June 17Th

- Page 207 and 208: PPoster Session, Thursday, June 17T

- Page 209 and 210: PPoster Session, Thursday, June 17T

- Page 211: Poster Session, Thursday, June 17AF