FR-F700 INSTRUCTION MANUAL (BASIC) - MRO Stop

FR-F700 INSTRUCTION MANUAL (BASIC) - MRO Stop

FR-F700 INSTRUCTION MANUAL (BASIC) - MRO Stop

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

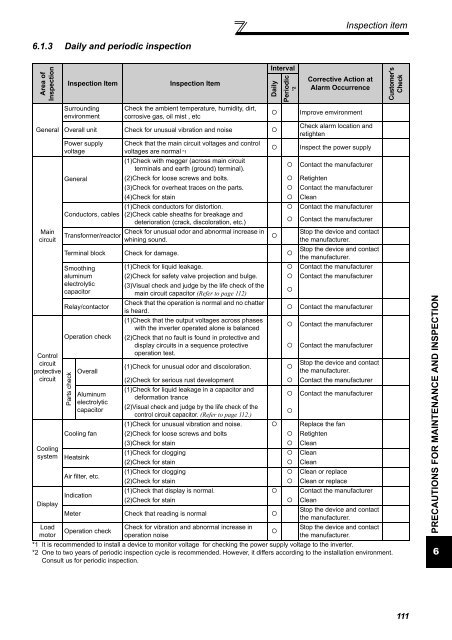

Inspection item6.1.3 Daily and periodic inspectionArea ofInspectionGeneralMaincircuitControlcircuitprotectivecircuitCoolingsystemDisplayLoadmotorInspection ItemSurroundingenvironmentInspection ItemCheck the ambient temperature, humidity, dirt,corrosive gas, oil mist , etcOverall unit Check for unusual vibration and noise ◦Power supplyvoltageGeneralConductors, cablesTransformer/reactorCheck that the main circuit voltages and controlvoltages are normal *1IntervalCorrective Action atAlarm Occurrence*1 It is recommended to install a device to monitor voltage for checking the power supply voltage to the inverter.*2 One to two years of periodic inspection cycle is recommended. However, it differs according to the installation environment.Consult us for periodic inspection.DailyPeriodic*2◦ Improve emvironmentCheck alarm location andretighten◦ Inspect the power supply(1)Check with megger (across main circuitterminals and earth (ground) terminal).◦ Contact the manufacturer(2)Check for loose screws and bolts. ◦ Retighten(3)Check for overheat traces on the parts. ◦ Contact the manufacturer(4)Check for stain ◦ Clean(1)Check conductors for distortion.(2)Check cable sheaths for breakage anddeterioration (crack, discoloration, etc.)Check for unusual odor and abnormal increase inwhining sound.◦Terminal block Check for damage. ◦SmoothingaluminumelectrolyticcapacitorRelay/contactorOperation checkParts checkOverallAluminumelectrolyticcapacitorCooling fanHeatsinkAir filter, etc.Indication◦ Contact the manufacturer◦ Contact the manufacturer<strong>Stop</strong> the device and contactthe manufacturer.<strong>Stop</strong> the device and contactthe manufacturer.(1)Check for liquid leakage. ◦ Contact the manufacturer(2)Check for safety valve projection and bulge. ◦ Contact the manufacturer(3)Visual check and judge by the life check of themain circuit capacitor (Refer to page 112)◦Check that the operation is normal and no chatteris heard.(1)Check that the output voltages across phaseswith the inverter operated alone is balanced(2)Check that no fault is found in protective anddisplay circuits in a sequence protectiveoperation test.◦ Contact the manufacturer◦ Contact the manufacturer◦ Contact the manufacturer(1)Check for unusual odor and discoloration. ◦<strong>Stop</strong> the device and contactthe manufacturer.(2)Check for serious rust development ◦ Contact the manufacturer(1)Check for liquid leakage in a capacitor anddeformation trance(2)Visual check and judge by the life check of thecontrol circuit capacitor. (Refer to page 112.)◦ Contact the manufacturer◦(1)Check for unusual vibration and noise. ◦ Replace the fan(2)Check for loose screws and bolts ◦ Retighten(3)Check for stain ◦ Clean(1)Check for clogging ◦ Clean(2)Check for stain ◦ Clean(1)Check for clogging ◦ Clean or replace(2)Check for stain ◦ Clean or replace(1)Check that display is normal. ◦ Contact the manufacturer(2)Check for stain ◦ CleanMeter Check that reading is normal ◦Operation checkCheck for vibration and abnormal increase inoperation noise◦<strong>Stop</strong> the device and contactthe manufacturer.<strong>Stop</strong> the device and contactthe manufacturer.Customer'sCheckPRECAUTIONS FOR MAINTENANCE AND INSPECTION6111