- Page 1 and 2:

IN-6 INTRODUCTION - Abbreviations U

- Page 3 and 4:

AT5715 AT5716 AUTOMATIC TRANSAXLE -

- Page 5 and 6:

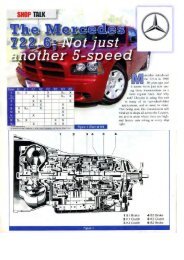

General Specifications Type of Tran

- Page 7 and 8:

FUNCTION OF COMPONENTS Component Fu

- Page 9 and 10:

Hydraulic Control System The hydrau

- Page 11 and 12:

AX-102 AT7927 A241E A240L, A243L AT

- Page 13 and 14:

AX-104 A241E AT8032 A243L A240L AT3

- Page 15 and 16:

AX-106 N-m (kgf-cm, ft-lbf) ♦ Non

- Page 17 and 18:

AX-108 SST AT8061 AT8078 AT8059 Pin

- Page 19 and 20:

AX-1 10 AT8497 AT2980 AT8058 AT2981

- Page 21 and 22:

AX-1 12 AT8484 AT8485 AT5831 AT7886

- Page 23 and 24:

AX-1 14 AT8005 AT8004 AUTOMATIC TRA

- Page 25 and 26:

AX-1 16 8. Be sure to install the t

- Page 27 and 28:

AX-1 18 AT2956 AT2911 AT0593 AT2910

- Page 29 and 30:

AX-120 AT0544 AT0700 AT0701 AT7931

- Page 31 and 32:

AX-122 AT2961 AT2901 AT2900 AT2899

- Page 33 and 34:

AX-124 AT8482 AT7999 AT1293 AT1294

- Page 35 and 36:

AX-126 AT0604 AT0523 AT2892 AT8034

- Page 37 and 38:

AX-128 AT0607 AT5829 AT3139 AT0610

- Page 39 and 40:

AX-130 AT5704 AT2965 AT2966 AT0798

- Page 41 and 42:

AX-132 AT2592 AT7891 AT0626 AT0627

- Page 43 and 44:

AX-134 AT2968 AT2023 AT2969 AT0635

- Page 45 and 46:

AX-136 AT0525 AT8484 AT5711 AT2766

- Page 47 and 48:

AX-138 AT2869 AT2867 AT2865 AT8302

- Page 49 and 50:

AX-140 AT5707 AT0643 AT5692 AT7991

- Page 51 and 52:

AX-142 AT5685 AT2975 AT2855 AT2854

- Page 53 and 54:

AX-144 AT5684 AT7926 AT7887 AT5683

- Page 55 and 56:

AX-146 AT5639 AT5730 AT7762 AT5638

- Page 57 and 58:

AX-148 22 (225, 16) Snap Ring Disc

- Page 59 and 60:

AX-150 AT8074 AT8069 AT8496 AT8079

- Page 61 and 62:

AX-152 AT2850 AT8071 AT8051 AT8057

- Page 63 and 64:

AX-154 AT0653 AT3135 AT3433 AT0108

- Page 65 and 66:

AX-156 AT3111 AT2863 AT3141 AT2865

- Page 67 and 68:

AX-158 A AT0352 AT3035 AT8049 AT065

- Page 69 and 70:

AX-160 AT2877 AT2878 AT0518 AT7891

- Page 71 and 72:

AX-162 AT2883 AT2884 AT0139 AT2885

- Page 73 and 74:

AX-164 AT2892 AT0523 AT0376 AT2888

- Page 75 and 76:

AX-166 AT0627 AT2893 AT7996 AT2895

- Page 77 and 78:

AX-168 AT8072 AT7999 AT2897 AT7889

- Page 79 and 80:

AX-170 AT0541 AT8058 AT0543 AT0544

- Page 81 and 82:

AX-172 AT2907 AT2908 Torx Wrench AT

- Page 83 and 84:

AX-174 AT7994 AT7995 SST AUTOMATIC

- Page 85 and 86:

Thrust Washer Direct Clutch Race Oi

- Page 87 and 88:

COMPONENT PARTS (See page AX-48 to

- Page 89 and 90:

AT8355 AT8356 AT8357 AT8358 AT8359

- Page 91 and 92:

Primary Regulator Valve Sleeve AT33

- Page 93 and 94:

AT3381 AT3380 Key 3 - 4 Shift Valve

- Page 95 and 96:

AT3383 AT3385 AT3389 AT3387 AUTOMAT

- Page 97 and 98:

AT8361 AT8362 AT3408 AT8368 AT8369

- Page 99 and 100:

AT8366 AT8367 AT8371 AUTOMATIC TRAN

- Page 101 and 102:

AT8270 AT8261 AT8262 AT8263 AT8264

- Page 103 and 104:

AT8279 AT8280 AT8271 SST AT7754 AT8

- Page 105 and 106:

AT7750 AT7751 AT7752 AT8287 AT8286

- Page 107 and 108:

AT8471 AT7753 SST AT7754 AT3498 AT8

- Page 109 and 110:

AT8375 AT8284 AT8277 AT8285 AT8296

- Page 111 and 112:

AT8299 AT8300 AT8291 AUTOMATIC TRAN

- Page 113 and 114:

♦ O-Ring 5.4 (55, 48 in.-lbf) AUT

- Page 115 and 116:

29 (300, 22) Governor Driven Gear U

- Page 117 and 118:

AT5652 AT2848 AT2849 AT2850 AT2851

- Page 119 and 120:

AT5684 AT7932 AT2852 AT0102 AT0103

- Page 121 and 122: A240L A243L AT3135 A241E AT2584 AT3

- Page 123 and 124: AT2861 AT3111 AT2863 AT3141 AT2865

- Page 125 and 126: AT2872 AT0352 AT3035 AT0651 AT0652

- Page 127 and 128: AT5596 AT2878 AT5648 AT7891 AT0519

- Page 129 and 130: AT2884 AT0139 AT2885 AT0324 AT7892

- Page 131 and 132: AT2892 AT0523 Ex. A240L AT0525 AT05

- Page 133 and 134: AT0530 AT0531 AT0532 AT0533 AT2896

- Page 135 and 136: AT2899 AT2900 AT2901 AT2902 AT2903

- Page 137 and 138: AT0541 AT0542 AT0543 AT0544 AT2904

- Page 139 and 140: AT2908 Q00981 AT2910 AT0555 AT2911

- Page 141 and 142: AT4331 AUTOMATIC TRANSAXLE (A241H)

- Page 143 and 144: Front Bearing Race Thrust Bering Re

- Page 145 and 146: AT5696 Torx Wrench AT5643 AT0548 AT

- Page 147 and 148: AT2960 AT2961 AT2901 AT2900 AT2899

- Page 149 and 150: AT7987 AT8072 AT7999 AT1293 AT1294

- Page 151 and 152: AT0076 AT0604 AT2962 AT2963 AT8483

- Page 153 and 154: AT2893 AT0527 AT0526 AT0606 AT0607

- Page 155 and 156: AT0612 AT0613 AT0323 AT0614 AT2965

- Page 157 and 158: AT2967 AT0620 AT0621 AT0622 AT2592

- Page 159 and 160: AT2759 AT0631 AT2593 AT2868 AT2023

- Page 161 and 162: AT1984 AT0381 AT2971 AT2595 AT3348

- Page 163 and 164: AT8047 AT3345 AT2870 AT2869 AT2867

- Page 165 and 166: AT0643 AT3114 AT0108 AT0645 AT3433

- Page 167 and 168: AT5645 AT3440 AT7992 AT8499 AT8057

- Page 169 and 170: AT0501 AT8040 AT8006 AT7762 AT8041

- Page 171: AT8074 AT3447 AUTOMATIC TRANSAXLE (

- Page 175 and 176: AX-50 AT7707 Less than 5 mm (0.20 i

- Page 177 and 178: AX-52 AT3611 AT2732 AT0153 AT0154 A

- Page 179 and 180: AX-54 AT3611 AT0159 AT0160 AT0161 A

- Page 181 and 182: AX-56 AT0163 AT2733 AT2734 AT0165 A

- Page 183 and 184: AX-58 A241E AT3617 AT5832 AT7710 Fl

- Page 185 and 186: AT0187 AT2740 AT8081 AT2739 AT0187

- Page 187 and 188: ♦ Non-reusable part AT7716 AT2742

- Page 189 and 190: AT2699 AT0191 AT0323 Hold Align Sna

- Page 191 and 192: AT0323 AT7717 AT8055 AT7717 AT4304

- Page 193 and 194: AT2919 AT0200 AT2920 Front Bearing

- Page 195 and 196: N-m (kgf-cm, ft-lbf) Non-reusable p

- Page 197 and 198: AT0565 AT2928 AT2929 AT2930 AT2931

- Page 199 and 200: AT0581 AT2934 AT7921 AT2929 AT0582

- Page 201 and 202: AT0589 AT0590 AT2938 AT0588 AT2939

- Page 203 and 204: ♦ Non-reusable part AT2942 AT0572

- Page 205 and 206: AT5834 AT5837 AT0576 AT0577 AT2948

- Page 207 and 208: Flange Disc Plate AT3113 AT2952 AT2

- Page 209 and 210: A241E ♦ Gasket Plate ♦ O-Ring N

- Page 211 and 212: A241E AT8032 A240L, A243L AT3048 AT

- Page 213 and 214: Check Ball Primary Regulator Plunge

- Page 215 and 216: LOCATION OF KEYS, PINS, VIBRATING S

- Page 217 and 218: SPECIFICATIONS OF VALVE BODY SPRING

- Page 219 and 220: A240L, A243L AT3051 AT3052 Plug Key

- Page 221 and 222: LOCATION OF KEYS AND STRAINER A240L

- Page 223 and 224:

IN-4 Seal Lock Adhesive IN0036 INTR

- Page 225 and 226:

IN-2 ♦ Oil Seal N-m (kgf-cm, ft-l

- Page 227 and 228:

TR-40 SERVICE SPECIFICATIONS SERVIC

- Page 229 and 230:

AX-232 SERVICE SPECIFICATIONS SERVI

- Page 231 and 232:

AX-234 SERVICE DATA (Cont’d) Accu

- Page 233 and 234:

AX-236 SERVICE DATA (Cont’d) Diff

- Page 235 and 236:

AX-12 Illustration Part No. Part Na

- Page 237 and 238:

AX-14 SST (SPECIAL SERVICE TOOLS) (

- Page 239 and 240:

STANDARD BOLT TORQUE SPECIFICATIONS

- Page 241 and 242:

TR-2 29 (300, 22) Transfer Right Ca

- Page 243 and 244:

TR-4 AT3354 AT3360 AT3364 AT3362 AT

- Page 245 and 246:

TR-6 AT7764 AT3357 AT3448 SST SST T

- Page 247 and 248:

TR-8 AT7767 AT7768 AT7769 AT8089 AT

- Page 249 and 250:

TR-10 AT7776 AT7777 SST TRANSFER (A

- Page 251 and 252:

TR-12 AT8009 AT7778 AT3342 AT7779 A

- Page 253 and 254:

TR-14 N-m (kgf-cm, ft-lbf) ♦ Non-

- Page 255 and 256:

TR-16 AT8068 AT8063 TRANSFER (A241H

- Page 257 and 258:

TR-18 AT7782 Matchmarks AT7783 AT77

- Page 259 and 260:

TR-20 AT7790 AT8354 AT7791 AT7792 S

- Page 261 and 262:

TR-22 AT7794 AT7788 AT7795 AT7787 -

- Page 263 and 264:

TR-24 AT7798 AT7787 AT7786 Matchmar

- Page 265 and 266:

TR-26 Transfer Shift Lever Shaft Di

- Page 267 and 268:

TR-28 AT8054 AT8064 AT8243 AT8244 A

- Page 269 and 270:

TR-30 AT8245 AT8244 AT3401 AT8260 A

- Page 271 and 272:

TR-32 AT8115 AT8267 AT8268 Adjustin

- Page 273 and 274:

TR-34 AT3361 AT3360 AT3308 AT3358 A

- Page 275 and 276:

TR-36 AT3362 AT3357 AT3415 AT8115 A

- Page 277 and 278:

TR-38 AT3361 AT3312 AT3356 AT3354 A