1935 Cadillac - GM Heritage Center

1935 Cadillac - GM Heritage Center

1935 Cadillac - GM Heritage Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

105<br />

practicable. Burning the carbon, if properly<br />

done, will give good results on these engines at a<br />

much lower cost to the owner.<br />

If this method is used, the carbon should be<br />

allowed to burn slowly to obtain the best possible<br />

results. Quick burning will do only a partial<br />

job. The rate of combustion can be controlled<br />

by the proper regulation of the oxygen supply to<br />

the combustion chamber.<br />

While the carbon is being burned, particular<br />

care must be taken to prevent injury either to<br />

the valves or to the external fittings on the engine.<br />

The proper procedure is as follows:<br />

Remove the spark plug wires and distributor<br />

cover, or use a suitable asbestos cover plate to<br />

protect them during the burning operation.<br />

Remove all spark plugs.<br />

ENGINE<br />

The next step is a matter of extreme importance,<br />

that is, to be sure the valves are both closed in the<br />

cylinder being burned. If the valves are not<br />

closed, they are very likely to be overheated,<br />

causing them to warp.<br />

The only positive way to make sure the valves<br />

are closed is to use a test light and crank the engine<br />

to the firing point on that cylinder. See Fig. 20,<br />

Plate 38.<br />

Allow the carbon to burn slowly until it has all<br />

been burned.<br />

Burn out all of the left-hand cylinders first, in<br />

the order in which they fire; then burn the right<br />

hand cylinders. The firing order, is, of course,<br />

indicated on the distributor cap.<br />

Removal of carbon in the V-8 engines should<br />

be done by scraping as in the past.<br />

14. Main Bearing Clearance<br />

Use dial indicator and special fixture (Tool No<br />

HM-65530) for checking bearing clearances. If<br />

bearings are found to be worn beyond specified<br />

limits they should be replaced. Replacement<br />

bearings are furnished to exact size and do not<br />

require reaming or scraping. No shims or liners<br />

are used on the main bearings and no attempt<br />

should be made to take up if worn.<br />

Always install new wooden plugs in grooves in<br />

sides of rear main bearing cap in <strong>Cadillac</strong> engine<br />

to prevent oil leaks around the cap. These plugs<br />

should be well greased to facilitate installation in<br />

the grooves.-<br />

15. Cleaning Oil Filter on 370-D and 452-D<br />

A Cuno disc-type self-cleaning oil filter is used<br />

on the 370-D and 452-D cars.<br />

The oil, in circulating through the filter, passes<br />

between thin rotating discs, stacked one upon<br />

another, and separated a few thousandths of an<br />

inch by a series of thin stationary plates. The<br />

filtering discs are mounted on a shaft which<br />

extends above the filter and is connected to the<br />

brake linkage in such a way that the discs are<br />

rotated a partial turn each time the brakes are<br />

applied. -<br />

When the filtering discs are rotated the accumulated<br />

sediment is scraped off by the stationary<br />

plates and falls to the bottom of the tank.<br />

The only attention required is the draining of<br />

the tank every 6000 miles.<br />

16. Using Stud for Removing V-8 Cylinder<br />

Heads<br />

The cylinder blocks used on <strong>Cadillac</strong> V-8 cars<br />

are not equipped with studs for attaching the<br />

cylinder heads. Instead, cap screws are used<br />

because of the necessity of turning the head<br />

slightly counter-clockwise, when removing, to<br />

clear the hood shelf.<br />

When removing or installing cylinder heads,<br />

particular care must be taken to hold the head in<br />

position. If this precaution is not taken, there is<br />

a possibility of the head striking and bending<br />

those valves which are open.<br />

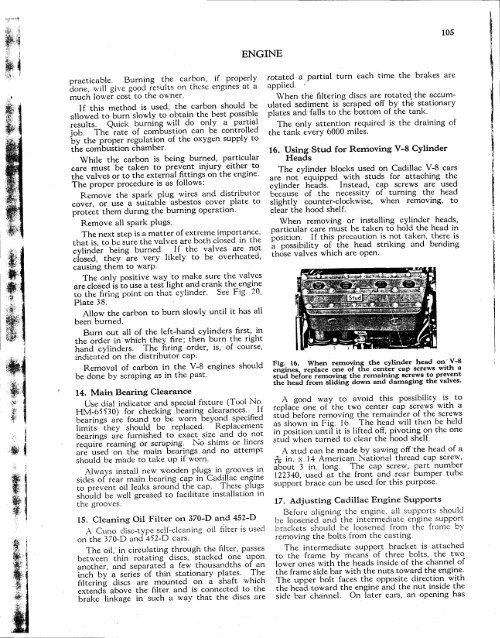

Fig. 16. When removing the cylinder head on V-8<br />

engines, replace one of the center cap screws with a<br />

stud before removing the remaining screws to prevent<br />

the head from sliding down and damaging the valves.<br />

A good way to avoid this possibility is to<br />

replace one of the two center cap screws with a<br />

stud before removing the remainder of the screws<br />

as shown in Fig. 16. The head will then be held<br />

in position until it is lifted off, pivoting on the one<br />

stud when turned to clear the hood shelf.<br />

A stud can be made by sawing off the head of a<br />

-r\ in. x 14 American National thread cap screw,<br />

about 3 in. long. The cap screw, part number<br />

122340, used at the front and rear bumper tube<br />

support brace can be used for this purpose.<br />

17. Adjusting <strong>Cadillac</strong> Engine Supports<br />

Before aligning the engine, all supports should<br />

be loosened and the intermediate engine support<br />

brackets should be loosened from the frame by<br />

removing the bolts from the casting.<br />

The intermediate support bracket is attached<br />

to the frame by means of three bolts, the two<br />

lower ones with the heads inside of the channel of<br />

the frame side bar with the nuts toward the engine.<br />

The upper bolt faces the opposite direction with<br />

the head toward the engine and the nut inside the<br />

side bar channel. On later cars, an opening has