Biofuels in Perspective

Biofuels in Perspective

Biofuels in Perspective

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

140 <strong>Biofuels</strong><br />

Ratio of <strong>in</strong>itial reaction rate (-)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0.0 0.5 1.0<br />

Fatty acid ratio <strong>in</strong>dicated by R f (-)<br />

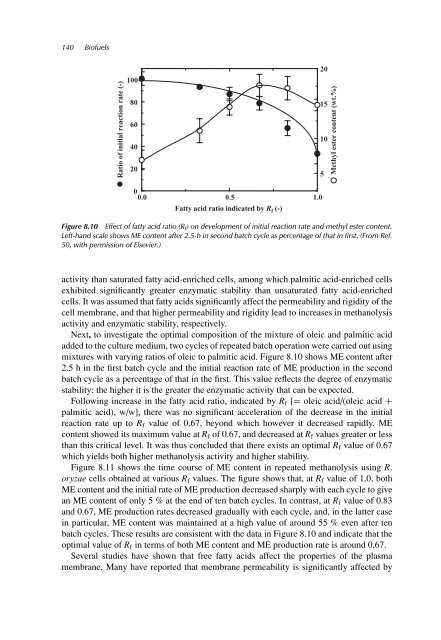

Figure 8.10 Effect of fatty acid ratio (R f) on development of <strong>in</strong>itial reaction rate and methyl ester content.<br />

Left-hand scale shows ME content after 2.5-h <strong>in</strong> second batch cycle as percentage of that <strong>in</strong> first. (From Ref.<br />

50, with permission of Elsevier.)<br />

activity than saturated fatty acid-enriched cells, among which palmitic acid-enriched cells<br />

exhibited significantly greater enzymatic stability than unsaturated fatty acid-enriched<br />

cells. It was assumed that fatty acids significantly affect the permeability and rigidity of the<br />

cell membrane, and that higher permeability and rigidity lead to <strong>in</strong>creases <strong>in</strong> methanolysis<br />

activity and enzymatic stability, respectively.<br />

Next, to <strong>in</strong>vestigate the optimal composition of the mixture of oleic and palmitic acid<br />

added to the culture medium, two cycles of repeated batch operation were carried out us<strong>in</strong>g<br />

mixtures with vary<strong>in</strong>g ratios of oleic to palmitic acid. Figure 8.10 shows ME content after<br />

2.5 h <strong>in</strong> the first batch cycle and the <strong>in</strong>itial reaction rate of ME production <strong>in</strong> the second<br />

batch cycle as a percentage of that <strong>in</strong> the first. This value reflects the degree of enzymatic<br />

stability: the higher it is the greater the enzymatic activity that can be expected.<br />

Follow<strong>in</strong>g <strong>in</strong>crease <strong>in</strong> the fatty acid ratio, <strong>in</strong>dicated by Rf [= oleic acid/(oleic acid +<br />

palmitic acid), w/w], there was no significant acceleration of the decrease <strong>in</strong> the <strong>in</strong>itial<br />

reaction rate up to Rf value of 0.67, beyond which however it decreased rapidly. ME<br />

content showed its maximum value at Rf of 0.67, and decreased at Rf values greater or less<br />

than this critical level. It was thus concluded that there exists an optimal Rf value of 0.67<br />

which yields both higher methanolysis activity and higher stability.<br />

Figure 8.11 shows the time course of ME content <strong>in</strong> repeated methanolysis us<strong>in</strong>g R.<br />

oryzae cells obta<strong>in</strong>ed at various Rf values. The figure shows that, at Rf value of 1.0, both<br />

ME content and the <strong>in</strong>itial rate of ME production decreased sharply with each cycle to give<br />

an ME content of only 5 % at the end of ten batch cycles. In contrast, at Rf value of 0.83<br />

and 0.67, ME production rates decreased gradually with each cycle, and, <strong>in</strong> the latter case<br />

<strong>in</strong> particular, ME content was ma<strong>in</strong>ta<strong>in</strong>ed at a high value of around 55 % even after ten<br />

batch cycles. These results are consistent with the data <strong>in</strong> Figure 8.10 and <strong>in</strong>dicate that the<br />

optimal value of Rf <strong>in</strong> terms of both ME content and ME production rate is around 0.67.<br />

Several studies have shown that free fatty acids affect the properties of the plasma<br />

membrane. Many have reported that membrane permeability is significantly affected by<br />

20<br />

15<br />

10<br />

5<br />

Methyl ester content (wt.%)