Biofuels in Perspective

Biofuels in Perspective

Biofuels in Perspective

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Susta<strong>in</strong>able Production of Cellulosic Feedstock 31<br />

Table 2.7 Biomass ref<strong>in</strong><strong>in</strong>g Consortium for Applied Fundamentals and Innovation (CAFI) collaborative<br />

pretreatment <strong>in</strong>vestigators<br />

Institution Process<br />

Auburn University (Y.Y. Lee) Ammonia Recycle Percolation (ARP)<br />

University of British Columbia (Jack Saddler) SO2 steam explosion<br />

University of California, Riverside (Charles Wyman) Dilute acid treatment<br />

Michigan State University (Bruce Dale) Ammonia Fiber Explosion (AFEX)<br />

Purdue University (Michael Ladisch, Nathan Mosier) Hot water, controlled pH<br />

Texas A&M University (Mark Holtzapple) Lime treatment<br />

National Renewable Energy Laboratory (NREL)<br />

(Rick Elander, Tim Eggeman)<br />

Feed stock supply and characterization/<br />

economic analysis<br />

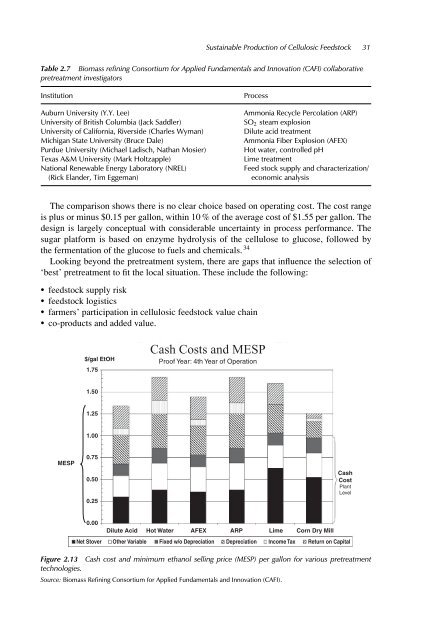

The comparison shows there is no clear choice based on operat<strong>in</strong>g cost. The cost range<br />

is plus or m<strong>in</strong>us $0.15 per gallon, with<strong>in</strong> 10 % of the average cost of $1.55 per gallon. The<br />

design is largely conceptual with considerable uncerta<strong>in</strong>ty <strong>in</strong> process performance. The<br />

sugar platform is based on enzyme hydrolysis of the cellulose to glucose, followed by<br />

the fermentation of the glucose to fuels and chemicals. 34<br />

Look<strong>in</strong>g beyond the pretreatment system, there are gaps that <strong>in</strong>fluence the selection of<br />

‘best’ pretreatment to fit the local situation. These <strong>in</strong>clude the follow<strong>in</strong>g:<br />

� feedstock supply risk<br />

� feedstock logistics<br />

� farmers’ participation <strong>in</strong> cellulosic feedstock value cha<strong>in</strong><br />

� co-products and added value.<br />

MESP<br />

Cash Costs and MESP<br />

$/gal EtOH Proof Year: 4th Year of Operation<br />

1.75<br />

1.50<br />

1.25<br />

1.00<br />

0.75<br />

0.50<br />

0.25<br />

Cash<br />

Cost<br />

Plant<br />

Level<br />

0.00<br />

Dilute Acid Hot Water AFEX ARP Lime Corn Dry Mill<br />

Net Stover Other Variable Fixed w/o Depreciation Depreciation Income Tax Return on Capital<br />

Figure 2.13 Cash cost and m<strong>in</strong>imum ethanol sell<strong>in</strong>g price (MESP) per gallon for various pretreatment<br />

technologies.<br />

Source: Biomass Ref<strong>in</strong><strong>in</strong>g Consortium for Applied Fundamentals and Innovation (CAFI).