Biofuels in Perspective

Biofuels in Perspective

Biofuels in Perspective

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Susta<strong>in</strong>able Production of Cellulosic Feedstock 29<br />

concentrations. The Chicago Climate Exchange (CCX), a voluntary greenhouse gas trad<strong>in</strong>g<br />

market, allows farmers to sell the climate benefits of their cropp<strong>in</strong>g practice to <strong>in</strong>dustries<br />

wish<strong>in</strong>g to offset their emissions. The Exchange offers farmers a conservative 0.5 metric ton<br />

per acre ‘exchange soil offset’ credit for no-till operations, which translates to roughly $1<br />

per acre at current CCX credit prices of $1.65 to $2.00 per metric ton CO2. The Iowa Farm<br />

Bureau and other regional growers associations have organized farmers to collectively sell<br />

their credits on the CCX market.<br />

In European markets, where mandatory limits on greenhouse gas emissions exist, carbon<br />

credit prices have ranged between $10 and $30 per metric ton CO2, suggest<strong>in</strong>g that if<br />

mandatory greenhouse gas emissions limits are established <strong>in</strong> the United States, benefits to<br />

farmers of no-till adoption could exceed $10 per acre, further driv<strong>in</strong>g the transition to no-till.<br />

2.11 Pretreatment<br />

In addition to the challenges of susta<strong>in</strong>able production, collection and transport, cellulosic<br />

biomass presents a unique problem <strong>in</strong> that, unlike traditional starch feedstocks, it is not<br />

readily hydrolyzed <strong>in</strong>to usable sugars. Cellulosic biomass must first be ‘pre-treated’ to<br />

make the sugars available to chemical or biological hydrolysis.<br />

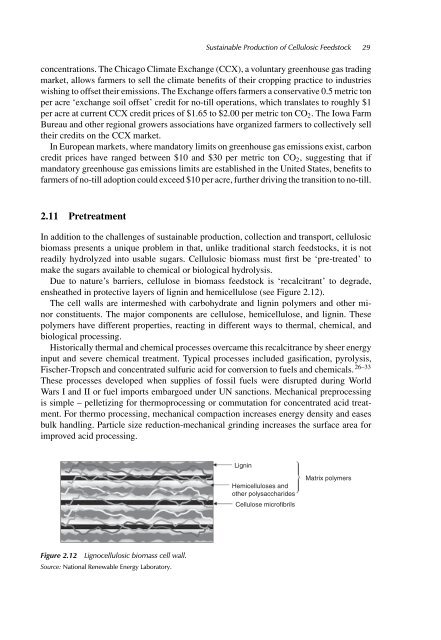

Due to nature’s barriers, cellulose <strong>in</strong> biomass feedstock is ‘recalcitrant’ to degrade,<br />

ensheathed <strong>in</strong> protective layers of lign<strong>in</strong> and hemicellulose (see Figure 2.12).<br />

The cell walls are <strong>in</strong>termeshed with carbohydrate and lign<strong>in</strong> polymers and other m<strong>in</strong>or<br />

constituents. The major components are cellulose, hemicellulose, and lign<strong>in</strong>. These<br />

polymers have different properties, react<strong>in</strong>g <strong>in</strong> different ways to thermal, chemical, and<br />

biological process<strong>in</strong>g.<br />

Historically thermal and chemical processes overcame this recalcitrance by sheer energy<br />

<strong>in</strong>put and severe chemical treatment. Typical processes <strong>in</strong>cluded gasification, pyrolysis,<br />

Fischer-Tropsch and concentrated sulfuric acid for conversion to fuels and chemicals. 26–33<br />

These processes developed when supplies of fossil fuels were disrupted dur<strong>in</strong>g World<br />

Wars I and II or fuel imports embargoed under UN sanctions. Mechanical preprocess<strong>in</strong>g<br />

is simple – pelletiz<strong>in</strong>g for thermoprocess<strong>in</strong>g or commutation for concentrated acid treatment.<br />

For thermo process<strong>in</strong>g, mechanical compaction <strong>in</strong>creases energy density and eases<br />

bulk handl<strong>in</strong>g. Particle size reduction-mechanical gr<strong>in</strong>d<strong>in</strong>g <strong>in</strong>creases the surface area for<br />

improved acid process<strong>in</strong>g.<br />

Figure 2.12 Lignocellulosic biomass cell wall.<br />

Source: National Renewable Energy Laboratory.<br />

Lign<strong>in</strong><br />

Hemicelluloses and<br />

other polysaccharides<br />

Cellulose microfibrils<br />

Matrix polymers