Chapter 1. Color Management Background - Kodak

Chapter 1. Color Management Background - Kodak

Chapter 1. Color Management Background - Kodak

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

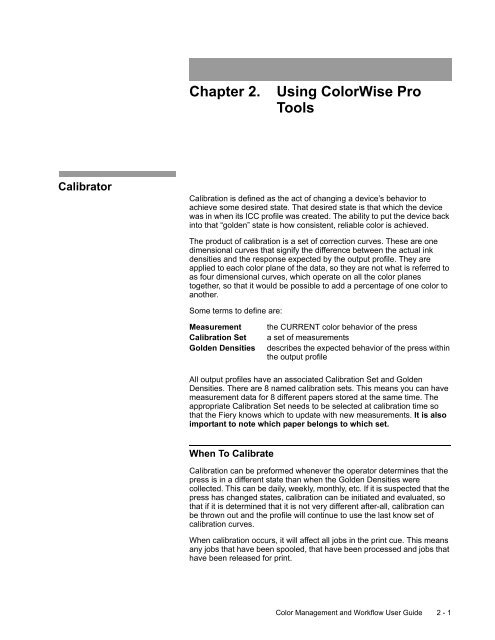

<strong>Chapter</strong> 2.<br />

Using <strong>Color</strong>Wise Pro<br />

Tools<br />

Calibrator<br />

Calibration is defined as the act of changing a device’s behavior to<br />

achieve some desired state. That desired state is that which the device<br />

was in when its ICC profile was created. The ability to put the device back<br />

into that “golden” state is how consistent, reliable color is achieved.<br />

The product of calibration is a set of correction curves. These are one<br />

dimensional curves that signify the difference between the actual ink<br />

densities and the response expected by the output profile. They are<br />

applied to each color plane of the data, so they are not what is referred to<br />

as four dimensional curves, which operate on all the color planes<br />

together, so that it would be possible to add a percentage of one color to<br />

another.<br />

Some terms to define are:<br />

Measurement<br />

Calibration Set<br />

Golden Densities<br />

the CURRENT color behavior of the press<br />

a set of measurements<br />

describes the expected behavior of the press within<br />

the output profile<br />

All output profiles have an associated Calibration Set and Golden<br />

Densities. There are 8 named calibration sets. This means you can have<br />

measurement data for 8 different papers stored at the same time. The<br />

appropriate Calibration Set needs to be selected at calibration time so<br />

that the Fiery knows which to update with new measurements. It is also<br />

important to note which paper belongs to which set.<br />

When To Calibrate<br />

Calibration can be preformed whenever the operator determines that the<br />

press is in a different state than when the Golden Densities were<br />

collected. This can be daily, weekly, monthly, etc. If it is suspected that the<br />

press has changed states, calibration can be initiated and evaluated, so<br />

that if it is determined that it is not very different after-all, calibration can<br />

be thrown out and the profile will continue to use the last know set of<br />

calibration curves.<br />

When calibration occurs, it will affect all jobs in the print cue. This means<br />

any jobs that have been spooled, that have been processed and jobs that<br />

have been released for print.<br />

<strong>Color</strong> <strong>Management</strong> and Workflow User Guide 2 - 1