STX Signal Transmitter Installation and Operation ... - Kistler-Morse

STX Signal Transmitter Installation and Operation ... - Kistler-Morse

STX Signal Transmitter Installation and Operation ... - Kistler-Morse

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

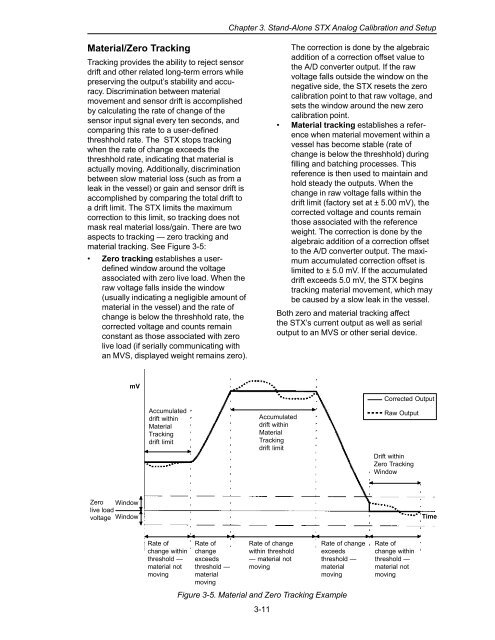

Chapter 3. St<strong>and</strong>-Alone <strong>STX</strong> Analog Calibration <strong>and</strong> Setup<br />

Material/Zero Tracking<br />

Tracking provides the ability to reject sensor<br />

drift <strong>and</strong> other related long-term errors while<br />

preserving the output’s stability <strong>and</strong> accuracy.<br />

Discrimination between material<br />

movement <strong>and</strong> sensor drift is accomplished<br />

by calculating the rate of change of the<br />

sensor input signal every ten seconds, <strong>and</strong><br />

comparing this rate to a user-defined<br />

threshhold rate. The <strong>STX</strong> stops tracking<br />

when the rate of change exceeds the<br />

threshhold rate, indicating that material is<br />

actually moving. Additionally, discrimination<br />

between slow material loss (such as from a<br />

leak in the vessel) or gain <strong>and</strong> sensor drift is<br />

accomplished by comparing the total drift to<br />

a drift limit. The <strong>STX</strong> limits the maximum<br />

correction to this limit, so tracking does not<br />

mask real material loss/gain. There are two<br />

aspects to tracking — zero tracking <strong>and</strong><br />

material tracking. See Figure 3-5:<br />

• Zero tracking establishes a userdefined<br />

window around the voltage<br />

associated with zero live load. When the<br />

raw voltage falls inside the window<br />

(usually indicating a negligible amount of<br />

material in the vessel) <strong>and</strong> the rate of<br />

change is below the threshhold rate, the<br />

corrected voltage <strong>and</strong> counts remain<br />

constant as those associated with zero<br />

live load (if serially communicating with<br />

an MVS, displayed weight remains zero).<br />

The correction is done by the algebraic<br />

addition of a correction offset value to<br />

the A/D converter output. If the raw<br />

voltage falls outside the window on the<br />

negative side, the <strong>STX</strong> resets the zero<br />

calibration point to that raw voltage, <strong>and</strong><br />

sets the window around the new zero<br />

calibration point.<br />

• Material tracking establishes a reference<br />

when material movement within a<br />

vessel has become stable (rate of<br />

change is below the threshhold) during<br />

filling <strong>and</strong> batching processes. This<br />

reference is then used to maintain <strong>and</strong><br />

hold steady the outputs. When the<br />

change in raw voltage falls within the<br />

drift limit (factory set at ± 5.00 mV), the<br />

corrected voltage <strong>and</strong> counts remain<br />

those associated with the reference<br />

weight. The correction is done by the<br />

algebraic addition of a correction offset<br />

to the A/D converter output. The maximum<br />

accumulated correction offset is<br />

limited to ± 5.0 mV. If the accumulated<br />

drift exceeds 5.0 mV, the <strong>STX</strong> begins<br />

tracking material movement, which may<br />

be caused by a slow leak in the vessel.<br />

Both zero <strong>and</strong> material tracking affect<br />

the <strong>STX</strong>’s current output as well as serial<br />

output to an MVS or other serial device.<br />

mV<br />

Accumulated<br />

drift within<br />

Material<br />

Tracking<br />

drift limit<br />

Accumulated<br />

drift within<br />

Material<br />

Tracking<br />

drift limit<br />

Corrected Output<br />

Raw Output<br />

Drift within<br />

Zero Tracking<br />

Window<br />

Zero Window<br />

live load<br />

voltage Window<br />

Time<br />

Rate of<br />

change within<br />

threshold —<br />

material not<br />

moving<br />

Rate of<br />

change<br />

exceeds<br />

threshold —<br />

material<br />

moving<br />

Rate of change<br />

within threshold<br />

— material not<br />

moving<br />

Figure 3-5. Material <strong>and</strong> Zero Tracking Example<br />

3-11<br />

Rate of change<br />

exceeds<br />

threshold —<br />

material<br />

moving<br />

Rate of<br />

change within<br />

threshold —<br />

material not<br />

moving