- Page 2 and 3:

Sho2009SHO2009International Symposi

- Page 4 and 5:

This edition is published by the Po

- Page 6 and 7:

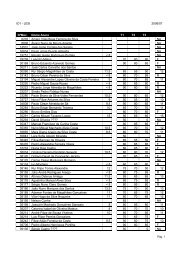

Index of author’s | Índice de au

- Page 8 and 9:

Oliveira. J. 85Pacciana, M. 335Pere

- Page 10 and 11:

Avaliação do risco de manipulaç

- Page 12 and 13:

PROGRAM | PROGRAMAColóquio interna

- Page 14 and 15:

Colóquio internacional sobre segur

- Page 16 and 17:

ForewordPreâmbuloThe Portuguese So

- Page 18 and 19:

PAPERS(by alphabetic order of the f

- Page 20 and 21:

A FUNÇÃO DOS DISPOSITIVOS MÉDICO

- Page 22 and 23:

- desenvolver posições nacionais,

- Page 24 and 25:

RISK EVALUATION OF HOUSEHOLD HAZARD

- Page 26 and 27:

containing lead and acids can harm

- Page 28 and 29:

People should become aware of the c

- Page 30 and 31:

GESTÃO INTEGRADA DA EMERGÊNCIA EC

- Page 32 and 33:

aeronaves; alteração ou eliminaç

- Page 34 and 35:

Tabela 8 - Avaliação do Nível de

- Page 36 and 37:

POLUENTES EMERGENTESArminda AlvesLE

- Page 38 and 39:

diclofenac - anti-inflamatório (83

- Page 40 and 41:

motoristas profissionais. Por outro

- Page 42 and 43:

UM QUADRO DE MATURIDADE ORGANIZACIO

- Page 44 and 45:

Management Association, fruto da co

- Page 46 and 47:

Os vértices da Figura 2 apontam pa

- Page 48 and 49:

26.Holliday, C.O., Schmidheiny, S.

- Page 50 and 51:

REFLEXÃO E ANÁLISE SOBRE A ORIGEM

- Page 52 and 53: Sho2009Figura 2 - Evolução do pes

- Page 54 and 55: assegurar a formação básica na

- Page 56 and 57: A IMPORTÂNCIA DA SEGURANÇA NO TRA

- Page 58 and 59: orientações que emanam do quadro

- Page 60 and 61: DETERMINAÇÃO DA CONCENTRAÇÃO DE

- Page 62 and 63: Sho2009Fig. 1 - Fracção total em

- Page 64 and 65: Relativamente às concentrações o

- Page 66 and 67: ANÁLISE DAS FONTES DE INCERTEZA E

- Page 68 and 69: 2.2 Incerteza padrão combinadaAs f

- Page 70 and 71: ANÁLISE ERGONÔMICA DO TRABALHO EM

- Page 72 and 73: Sho2009Figura 1 - Modelo de Perfil

- Page 74 and 75: Sho2009Figura 5 - Profissionograma

- Page 76 and 77: INDICADORES DE SEGURANÇA E SEU IMP

- Page 78 and 79: trabalho que possa causar acidente

- Page 80 and 81: Trabalho para a empresa contratante

- Page 82 and 83: INCLUSÃO DIGITAL DE INVISUAIS: AN

- Page 84 and 85: usado um outro programa leitor de e

- Page 86 and 87: AVALIAÇÃO E ANÁLISE ANTROPOMÉTR

- Page 88 and 89: Depois de estudadas as medidas actu

- Page 90 and 91: OCCUPATIONAL HEALTH AND SAFETYMANAG

- Page 92 and 93: Competence, training and awareness.

- Page 94 and 95: VAMOS CONVERSAR. COMPORTAMENTO SEGU

- Page 96 and 97: OS ESFORÇOS NOS PROFISSIONAIS DEEN

- Page 98 and 99: Foi aplicada a distribuição não

- Page 100 and 101: torções ou posturas de inclinaç

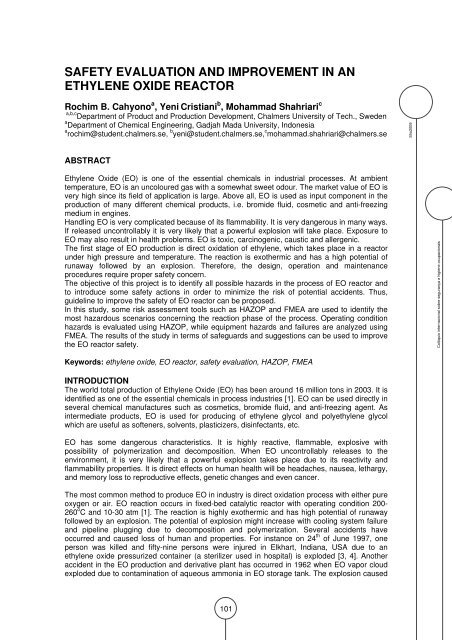

- Page 104 and 105: Sho2009Figure 1 - Ethylene Oxide (E

- Page 106 and 107: SEGURANÇA NA CONSTRUÇÃOSeguranç

- Page 108 and 109: Para cada situação e tipo de trab

- Page 110 and 111: • Qualquer fio partido ou desloca

- Page 112 and 113: QUESTIONÁRIO PARA AVALIAÇÃO DAS

- Page 114 and 115: algumas adaptações ao mesmo foram

- Page 116 and 117: 9. Daraiseh, N.; Genaidy, A.M., Kar

- Page 118 and 119: AUDITORIAS AOS SISTEMAS DE GESTÃO

- Page 120 and 121: Os desvios podem ser positivos (faz

- Page 122 and 123: • Melhor explicitação do concei

- Page 124 and 125: PREVENÇÃO E MINIMIZAÇÃO DO RISC

- Page 126 and 127: avaliadas caso a caso e de ser pond

- Page 128 and 129: Sho2009Figura 2. Delimitação e si

- Page 130 and 131: No entanto, há um domínio mais am

- Page 132 and 133: FUMO DE TABACO, ESPAÇOS INTERIORES

- Page 134 and 135: A actividade inalada pelo fumador a

- Page 136 and 137: [5] Carvalho, F.P. (1995a). 210 Po

- Page 138 and 139: CAPACIDADE PARA O TRABALHO DE SERVI

- Page 140 and 141: O projeto de pesquisa foi apresenta

- Page 142 and 143: Tabela 1.5: Correlações - Como vo

- Page 144 and 145: OPPORTUNITIES FOR ERROR RECOVERY RE

- Page 146 and 147: RESULTSThe potential for error exis

- Page 148 and 149: safe for use. The introduction of c

- Page 150 and 151: AVALIAÇÃO DO RISCO DE MANIPULAÇ

- Page 152 and 153:

como objectivos indicar aos utiliza

- Page 154 and 155:

Tabela 3. Classificação dos méto

- Page 156 and 157:

Em jeito de finalização, parece e

- Page 158 and 159:

IDENTIFICAÇÃO DAS NECESSIDADES DO

- Page 160 and 161:

elação custo-benefício das propo

- Page 162 and 163:

Três informações foram privilegi

- Page 164 and 165:

FORMAÇÃO EM CONTEXTO DE TRABALHO

- Page 166 and 167:

Suportando-nos no conhecimento adqu

- Page 168 and 169:

A transformação das condições d

- Page 170 and 171:

ENVELHECIMENTO E TRABALHO POR TURNO

- Page 172 and 173:

indicadas para a passagem para hor

- Page 174 and 175:

REFERÊNCIAS BIBLIOGRÁFICAS[1] Slu

- Page 176 and 177:

EVOLUÇÃO DA IDADE E CAPACIDADE DE

- Page 178 and 179:

Para o desenvolvimento do modelo co

- Page 180 and 181:

IMPLEMENTAÇÃO DA DIRECTIVA ATEX 1

- Page 182 and 183:

Na Directiva ATEX 137 são atribuí

- Page 184 and 185:

REFERÊNCIAS BIBLIOGRÁFICAS Comiss

- Page 186 and 187:

ENQUADRAMENTO TÉCNICO LEGAL DASACT

- Page 188 and 189:

Tal destaque implica uma qualifica

- Page 190 and 191:

estavam na agricultura, silvicultur

- Page 192 and 193:

REFERÊNCIAS BIBLIOGRÁFICAS1 Cabra

- Page 194 and 195:

FORMAÇÃO EM SEGURANÇA: UM ESTUDO

- Page 196 and 197:

segurança, à satisfação dos ind

- Page 198 and 199:

organizações que neles investem.

- Page 200 and 201:

O SECTOR SAÚDE E O IMPACTO DA PREV

- Page 202 and 203:

Além do acréscimo de preocupaçõ

- Page 204 and 205:

O Sector Saúde deve funcionar como

- Page 206 and 207:

AMBIENTE ESCOLAR: ASPECTOS DO POSTO

- Page 208 and 209:

O Gráfico 1 mostra diversos desali

- Page 210 and 211:

alunos e a queixa de dor osteomioar

- Page 212 and 213:

PERITACIÓN EN PREVENCIÓN DE RIESG

- Page 214 and 215:

FACTORES MATERIALES Y TECNOLÓGICOS

- Page 216 and 217:

daños y lesiones, de manera que en

- Page 218 and 219:

• La condiciones de seguridad•

- Page 220 and 221:

incorporadas al mismo. Dicho proced

- Page 222 and 223:

Consecuencias:• LIGERAMENTE DAÑI

- Page 224 and 225:

A FORMAÇÃO NO DOMÍNIO DA SEGURAN

- Page 226 and 227:

Nos aspectos da formação de TSHT,

- Page 228 and 229:

ANÁLISE E AVALIAÇÃO DE RISCOS NA

- Page 230 and 231:

Tabela 2 - Critérios Gravidade e P

- Page 232 and 233:

CONCLUSÕESForam identificados Peri

- Page 234 and 235:

INVESTIGATING THE EFFECTIVENESS OF

- Page 236 and 237:

Sixty percent of respondents were f

- Page 238 and 239:

PERFORMANCE OF HEARING PROTECTORS I

- Page 240 and 241:

Sho2009Fig.1 - Changes in attenuati

- Page 242 and 243:

Sho2009Figure 3 - Causes for higher

- Page 244 and 245:

PROPOSTA DE SISTEMA DE GESTÃO EM S

- Page 246 and 247:

formados 5 (cinco) ciclo de vistori

- Page 248 and 249:

de quantidade de acidentes. As orga

- Page 250 and 251:

CONFORTO TÉRMICO: ANÁLISE DOS FAT

- Page 252 and 253:

A idade média da amostra é de 25,

- Page 254 and 255:

Sho2009Tal situação pode ser expl

- Page 256 and 257:

COMO A INTEGIBILIDADE DA FALA E O D

- Page 258 and 259:

Plano AnalíticoApós a coleta dos

- Page 260 and 261:

fundamentos do nado de maneira sati

- Page 262 and 263:

ANÁLISE DOS FATORES DE RISCO À SA

- Page 264 and 265:

Com relação a manutenção dos ra

- Page 266 and 267:

sérios problemas à saúde dos mes

- Page 268 and 269:

GESTÃO DE RISCOS PROFISSIONAIS UMA

- Page 270 and 271:

iv.Avaliando a situação de risco

- Page 272 and 273:

Das posturas analisadas aplicando o

- Page 274 and 275:

MODELO DE ANÁLISE ERGONÓMICATRIDI

- Page 276 and 277:

2*Sho2009*6' 2433' 3 4! % 7Figura

- Page 278 and 279:

O Novo Modelo de Análise Ergonómi

- Page 280 and 281:

IMPLICAÇÕES DA UTILIZAÇÃO DE PR

- Page 282 and 283:

poderá ver-se envolvido numa situa

- Page 284 and 285:

acontece quando os sujeitos não ut

- Page 286 and 287:

FACETAS DA SEGURANÇA CONTRA RISCO

- Page 288 and 289:

Considerando que na inauguração d

- Page 290 and 291:

Tabela 5 - Reacção ao fogo.M0M1M2

- Page 292 and 293:

RISCO ASSOCIADO À EXPOSIÇÃO A VI

- Page 294 and 295:

A norma ISO 2631-1 [4] propõe os s

- Page 296 and 297:

A AVALIAÇÃO DE RISCOS NA FORÇA A

- Page 298 and 299:

CríticoEste nível é considerado

- Page 300 and 301:

Quadro 2 - Matriz do RiscoProbabili

- Page 302 and 303:

ANALYSING MSD RISK TO BLOCKLAYERS W

- Page 304 and 305:

The mean age of subjects was 37(12)

- Page 306 and 307:

ACKNOWLEDGEMENTSThis work was suppo

- Page 308 and 309:

NO CAMINHO DOS ZERO ACIDENTESJoão

- Page 310 and 311:

A Segurança fora do local de traba

- Page 312 and 313:

Realçaremos que a taxa de sinistra

- Page 314 and 315:

ERGONOMIA NA PREVENÇÃO DE LESÕES

- Page 316 and 317:

− Dimensionamento e Concepção d

- Page 318 and 319:

PROMOÇÃO DA PREVENÇÃO E SEGURAN

- Page 320 and 321:

METODOLOGIAA investigação contemp

- Page 322 and 323:

O professor enquanto homem “é um

- Page 324 and 325:

CONTRIBUTOS PARA O ESTUDO DO RUÍDO

- Page 326 and 327:

De cada conjunto de salas com as me

- Page 328 and 329:

65Sala 322 (JF+PA)65Sala 322 (JF+PF

- Page 330 and 331:

ABORDAGEM À PROBLEMÁTICA DA ILUMI

- Page 332 and 333:

Tabela 1: Resultados das medições

- Page 334 and 335:

foram maiores nos lugares perto da

- Page 336 and 337:

WORKERS’ TRAINING: A TOOL TO IMPR

- Page 338 and 339:

new starters, maintaining or updati

- Page 340 and 341:

OPERAÇÕES DE REABILITAÇÃO DE ED

- Page 342 and 343:

• a desvalorização das questõe

- Page 344 and 345:

4. CONCLUSÕES FINAISA intensifica

- Page 346 and 347:

TAREFAS DE MANIPULAÇÃO DE CARGAS:

- Page 348 and 349:

de Movimentação Manual (Força re

- Page 350 and 351:

BIBLIOGRAFIA1. Takala, J. (2007) Li

- Page 352 and 353:

A CHAVE DO SUCESSO DA AVALIAÇÃO D

- Page 354 and 355:

Nesta fase, para além dos trabalha

- Page 356 and 357:

A ideia de que os recursos humanos

- Page 358 and 359:

COOPERAÇÃO - NOVO PARADIGMA PARA

- Page 360 and 361:

Ilustração 4 - Fases do Processo

- Page 362 and 363:

estudos empíricos que suportem ou

- Page 364 and 365:

CONFORTO TÉRMICO EM SALAS DE AULAS

- Page 366 and 367:

Análise descritiva dos sujeitos da

- Page 368 and 369:

3) A sensação térmica dos profes

- Page 370 and 371:

AVALIAÇÃO DA EFICÁCIA DA HIGIENI

- Page 372 and 373:

A recolha de dados realizou-se em d

- Page 374 and 375:

Figura 2 - Total de Fungos ao longo

- Page 376 and 377:

AVALIAÇÃO DA CULTURA DE SEGURANÇ

- Page 378 and 379:

Quadro 1 - Avaliação do Clima de

- Page 380 and 381:

REFERÊNCIAS BIBLIOGRÁFICAS[1] Int

- Page 382 and 383:

A SEGURANÇA INDUSTRIAL NO QUADRO E

- Page 384 and 385:

Implementação e aplicaçãoA prim

- Page 386 and 387:

Salienta-se, no âmbito dos trabalh

- Page 388 and 389:

Artº 19º - Direito de votoArtº 2

- Page 390 and 391:

ANÁLISE DAS CAUSAS QUE ORIGINAM AC

- Page 392 and 393:

Tabela 2 - Faixa etária dos profis

- Page 394 and 395:

Tabela 7 - Local da lesão resultan

- Page 396 and 397:

UMA ABORDAGEM À UTILIZAÇÃO DOSEQ

- Page 398 and 399:

Este estudo teve por objectivo veri

- Page 400 and 401:

REFERÊNCIAS1 Lilja G, Wickman M (1

- Page 402 and 403:

CULTURA DE SEGURANÇA NA CONSTRUÇ

- Page 404 and 405:

numa óptica reflexiva sobre as sua

- Page 406 and 407:

ou seja a 1 ponto apenas, uma vez s

- Page 408 and 409:

cognitivos já anteriormente descri

- Page 410 and 411:

A SEGURANÇA E HIGIENE OCUPACIONAIS

- Page 412 and 413:

Sho2009... E cá dentroFigura 15 -

- Page 414 and 415:

EXPOSIÇÃO OCUPACIONAL A FUNGOS EX

- Page 416 and 417:

Cladosporium sp. (36,6%), Penicilli

- Page 418 and 419:

2. PASTUSZKA, J. et al. (2000) Bact

- Page 420 and 421:

EXPOSIÇÃO OCUPACIONAL AO FORMALDE

- Page 422 and 423:

Os resultados obtidos compararam-se

- Page 426 and 427:

Colóquio internacional sobre segur

- Page 428 and 429:

Colóquio internacional sobre segur

- Page 430 and 431:

Colóquio internacional sobre segur

- Page 432 and 433:

Colóquio internacional sobre segur

- Page 434 and 435:

Colóquio internacional sobre segur

- Page 436 and 437:

Colóquio internacional sobre segur

- Page 438 and 439:

Colóquio internacional sobre segur

- Page 440 and 441:

Colóquio internacional sobre segur

- Page 442 and 443:

Colóquio internacional sobre segur

- Page 444 and 445:

Colóquio internacional sobre segur

- Page 446 and 447:

Colóquio internacional sobre segur

- Page 448 and 449:

Colóquio internacional sobre segur

- Page 450 and 451:

Colóquio internacional sobre segur

- Page 452 and 453:

Colóquio internacional sobre segur

- Page 454 and 455:

Colóquio internacional sobre segur

- Page 456 and 457:

Colóquio internacional sobre segur

- Page 458 and 459:

Colóquio internacional sobre segur

- Page 460 and 461:

Colóquio internacional sobre segur

- Page 462 and 463:

Colóquio internacional sobre segur

- Page 464 and 465:

Colóquio internacional sobre segur

- Page 466 and 467:

Colóquio internacional sobre segur

- Page 468 and 469:

Colóquio internacional sobre segur

- Page 470 and 471:

Colóquio internacional sobre segur

- Page 472 and 473:

Colóquio internacional sobre segur

- Page 474 and 475:

Colóquio internacional sobre segur

- Page 476 and 477:

Colóquio internacional sobre segur

- Page 478 and 479:

Colóquio internacional sobre segur

- Page 480 and 481:

Colóquio internacional sobre segur

- Page 482 and 483:

Colóquio internacional sobre segur

- Page 484 and 485:

Colóquio internacional sobre segur

- Page 486 and 487:

Colóquio internacional sobre segur

- Page 488 and 489:

Colóquio internacional sobre segur

- Page 490 and 491:

Colóquio internacional sobre segur

- Page 492 and 493:

Colóquio internacional sobre segur

- Page 494 and 495:

Colóquio internacional sobre segur

- Page 496 and 497:

Colóquio internacional sobre segur

- Page 498:

Colóquio internacional sobre segur