- Page 2 and 3:

Strategic Action Plan for Integrate

- Page 4 and 5:

Strategic Action Plan Report Acknow

- Page 6 and 7:

Strategic Action Plan Report Figure

- Page 8 and 9:

Strategic Action Plan Report The Co

- Page 10 and 11:

Strategic Action Plan Report S1: Es

- Page 12 and 13:

streams is varying. The institution

- Page 14 and 15:

Strategic Action Plan Report Table

- Page 16 and 17:

Strategic Action Plan Report 3.5.2.

- Page 18 and 19:

Strategic Action Plan Report 7.1.1

- Page 20 and 21:

Strategic Action Plan Report 4.2 Vi

- Page 22 and 23:

Strategic Action Plan Report List o

- Page 24 and 25:

Strategic Action Plan Report MIDC M

- Page 26 and 27:

Strategic Action Plan Report projec

- Page 28 and 29:

Strategic Action Plan Report Figure

- Page 30 and 31:

Strategic Action Plan Report • Mo

- Page 32 and 33:

Strategic Action Plan Report This i

- Page 34 and 35:

Strategic Action Plan Report the Si

- Page 36 and 37:

Strategic Action Plan Report Chapte

- Page 38 and 39:

Strategic Action Plan Report Figure

- Page 40 and 41:

Strategic Action Plan Report 4. Pre

- Page 42 and 43:

Strategic Action Plan Report batter

- Page 44 and 45:

Strategic Action Plan Report electr

- Page 46 and 47:

Strategic Action Plan Report Chapte

- Page 48 and 49:

Strategic Action Plan Report Land-u

- Page 50 and 51:

Strategic Action Plan Report Figure

- Page 52 and 53:

Strategic Action Plan Report Figure

- Page 54 and 55:

Strategic Action Plan Report 3.4.2

- Page 56 and 57:

Strategic Action Plan Report a prel

- Page 58 and 59:

Strategic Action Plan Report Figure

- Page 60 and 61:

Strategic Action Plan Report The de

- Page 62 and 63:

Strategic Action Plan Report Figure

- Page 64 and 65:

Strategic Action Plan Report Figure

- Page 66 and 67:

Strategic Action Plan Report The wa

- Page 68 and 69:

Strategic Action Plan Report Table

- Page 70 and 71:

Strategic Action Plan Report MSW Co

- Page 72 and 73:

Strategic Action Plan Report Figure

- Page 74 and 75:

Strategic Action Plan Report Figure

- Page 76 and 77: Strategic Action Plan Report 3.5.1.

- Page 78 and 79: Although the numbers of vermi-compo

- Page 80 and 81: Figure 3.24: Location of the Existi

- Page 82 and 83: Figure 3.26: Typical Flow Diagram o

- Page 84 and 85: 3.5.3 Existing Management of C&D Wa

- Page 86 and 87: As can be observed from Figure 3.27

- Page 88 and 89: The implementation of the SWM funct

- Page 90 and 91: compliance, institutional capacitie

- Page 92 and 93: In the context of Bio-medical Waste

- Page 94 and 95: • The waste collection across the

- Page 96 and 97: probable gaps in waste related infr

- Page 98 and 99: egarding the implementation of all

- Page 100 and 101: 3.7.4 Financial Constraints In gene

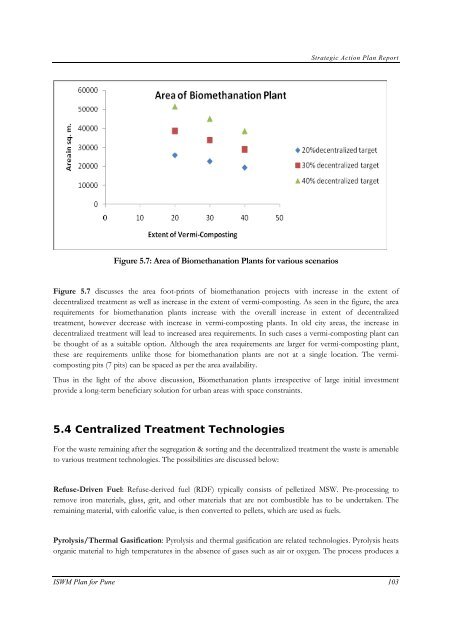

- Page 102 and 103: Strategic Action Plan Report 4.1 Ov

- Page 104 and 105: Strategic Action Plan Report Box 4.

- Page 106 and 107: Strategic Action Plan Report Vision

- Page 108 and 109: Strategic Action Plan Report • Ac

- Page 110 and 111: Strategic Action Plan Report This r

- Page 112 and 113: Strategic Action Plan Report 3. Phy

- Page 114 and 115: Strategic Action Plan Report In Pun

- Page 116 and 117: Strategic Action Plan Report As the

- Page 118 and 119: Strategic Action Plan Report S. N.

- Page 120 and 121: Strategic Action Plan Report • Ra

- Page 122 and 123: Strategic Action Plan Report 3) Ane

- Page 124 and 125: Strategic Action Plan Report The se

- Page 128 and 129: Strategic Action Plan Report mixtur

- Page 130 and 131: Strategic Action Plan Report Pyroly

- Page 132 and 133: Strategic Action Plan Report indust

- Page 134 and 135: Strategic Action Plan Report 3. Tre

- Page 136 and 137: 6. The Strategic Action Plan Strate

- Page 138 and 139: Strategic Action Plan Report Table

- Page 140 and 141: Strategic Action Plan Report Theme

- Page 142 and 143: Strategic Action Plan Report Theme

- Page 144 and 145: Strategic Action Plan Report Theme

- Page 146 and 147: Strategic Action Plan Report Theme

- Page 148 and 149: Strategic Action Plan Report The Sc

- Page 150 and 151: Strategic Action Plan Report Table

- Page 152 and 153: INVENTORIZATION OF SOLID WASTE Targ

- Page 154 and 155: DEVELOPMENT OF A MODEL FOR MUNICIPA

- Page 156 and 157: SECURING CARBON CREDITS THROUGH CLE

- Page 158 and 159: ASSESSMENT OF EXISTING WASTE DISPOS

- Page 160 and 161: IDENTIFICATION AND PRELIMINARY DESG

- Page 162 and 163: OPTIMISATION AND STRENGTHENING OF M

- Page 164 and 165: ESTABLISHMENT OF COMMUNITY SORTING

- Page 166 and 167: PILOT PROJECTS FOR RECYCLE AND REUS

- Page 168 and 169: RECYCLING OF PLASTIC WASTE 3 R INIT

- Page 170 and 171: ESTABLISH ELECTRONIC WASTE (E-WASTE

- Page 172 and 173: ESTABLISH A COMPACT FLUORESCENT LIG

- Page 174 and 175: ESTABLISHMENT OF ENVIRONMENTAL AWAR

- Page 176 and 177:

PRIVATE PARTNERSHIP IN CURRENT WAST

- Page 178 and 179:

PRIVATE PARTNERSHIPS IN DECENTRALIZ

- Page 180 and 181:

ESTABLISHMENT OF COMPOST COLLECTION

- Page 182 and 183:

DEMONSTRATION PROJECTS FOR HOTEL WA

- Page 184 and 185:

CONSTRUCTION AND DEMOLITION (C&D) W

- Page 186 and 187:

DESIGN AND LAUNCH OF A COMPREHENSIV

- Page 188 and 189:

TAMING CONSUMPTION OF NON- BIODEGRA

- Page 190 and 191:

IMPARTING AWARENESS AND TRAINING FO

- Page 192 and 193:

INITIATING SCHOOLS’ INVOLVEMENT I

- Page 194 and 195:

INTRODUCING AWARD SCHEMES Target:

- Page 196 and 197:

IMPROVISING WASTE MANAGEMENT DURING

- Page 198 and 199:

ESTABLISHMENT OF STANDARDIZED GUILD

- Page 200 and 201:

ESTABLISHMENT OF A CADRE OF CERTIFI

- Page 202 and 203:

Target: INTRODUCING INDUSTRY-UNIVER

- Page 204 and 205:

ESTABLISHMENT OF A WASTE EXCHANGE C

- Page 206 and 207:

ESTABLISHMENT OF THE INTEGRATED SOL

- Page 208 and 209:

DEVELOP AND INTRODUCE POLICY FOR CO

- Page 210 and 211:

IMPROVING HEALTH AND SAFETY OF PMC

- Page 212 and 213:

STRENGTHENING PMC RAG PICKER CO- OP

- Page 214 and 215:

Strategic Action Plan Report Chapte

- Page 216 and 217:

Strategic Action Plan Report Figure

- Page 218 and 219:

Strategic Action Plan Report Some o

- Page 220 and 221:

Strategic Action Plan Report Figure

- Page 222 and 223:

Strategic Action Plan Report Consul

- Page 224 and 225:

Strategic Action Plan Report A data

- Page 226 and 227:

Strategic Action Plan Report Figure

- Page 228 and 229:

Strategic Action Plan Report and IS

- Page 230 and 231:

as it is aimed at changing a certai

- Page 232 and 233:

During the preparation of ISWM Acti

- Page 234 and 235:

This website could be used by the I

- Page 236 and 237:

• Special training to unqualified

- Page 238 and 239:

As a part of the preparation of ISW

- Page 240 and 241:

Strategic Action Plan Report • Se

- Page 242 and 243:

Strategic Action Plan Report Table

- Page 244 and 245:

Strategic Action Plan Report Activi

- Page 246 and 247:

Strategic Action Plan Report Annexu

- Page 248 and 249:

Strategic Action Plan Report ISWM P

- Page 250 and 251:

Strategic Action Plan Report For Bh

- Page 252 and 253:

Strategic Action Plan Report For Dh

- Page 254 and 255:

Strategic Action Plan Report For Ka

- Page 256 and 257:

Strategic Action Plan Report For Sa

- Page 258 and 259:

Strategic Action Plan Report For Ti

- Page 260 and 261:

Strategic Action Plan Report For Wa

- Page 262 and 263:

Strategic Action Plan Report Annexu

- Page 264 and 265:

Strategic Action Plan Report pumpin

- Page 266 and 267:

Strategic Action Plan Report There

- Page 268 and 269:

Strategic Action Plan Report to cha

- Page 270 and 271:

Strategic Action Plan Report 6. Det

- Page 272 and 273:

Strategic Action Plan Report Annexu

- Page 274 and 275:

Strategic Action Plan Report Instit

- Page 276 and 277:

Strategic Action Plan Report Instit

- Page 278 and 279:

Strategic Action Plan Report Instit

- Page 280 and 281:

Strategic Action Plan Report Instit

- Page 282 and 283:

Strategic Action Plan Report Instit

- Page 284 and 285:

Strategic Action Plan Report Helped

- Page 286 and 287:

Strategic Action Plan Report The pr

- Page 288 and 289:

Strategic Action Plan Report The IS

- Page 290:

Strategic Action Plan Report 1400-1