Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

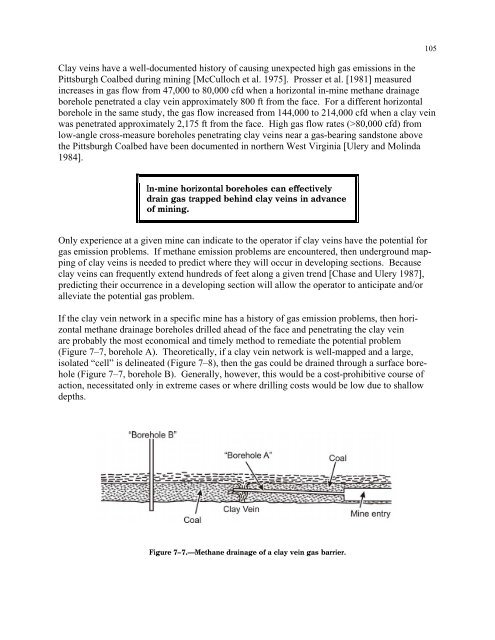

Clay ve<strong>in</strong>s have a well-documented history of caus<strong>in</strong>g unexpected high gas emissions <strong>in</strong> thePittsburgh Coalbed dur<strong>in</strong>g m<strong>in</strong><strong>in</strong>g [McCulloch et al. 1975]. Prosser et al. [1981] measured<strong>in</strong>creases <strong>in</strong> gas flow from 47,000 to 80,000 cfd when a horizontal <strong>in</strong>-m<strong>in</strong>e methane dra<strong>in</strong>ageborehole penetrated a clay ve<strong>in</strong> approximately 800 ft from the face. For a different horizontalborehole <strong>in</strong> the same study, the gas flow <strong>in</strong>creased from 144,000 to 214,000 cfd when a clay ve<strong>in</strong>was penetrated approximately 2,175 ft from the face. High gas flow rates (>80,000 cfd) fromlow-angle cross-measure boreholes penetrat<strong>in</strong>g clay ve<strong>in</strong>s near a gas-bear<strong>in</strong>g sandstone abovethe Pittsburgh Coalbed have been documented <strong>in</strong> northern West Virg<strong>in</strong>ia [Ulery and Mol<strong>in</strong>da1984].105In-m<strong>in</strong>e horizontal boreholes can effectivelydra<strong>in</strong> gas trapped beh<strong>in</strong>d clay ve<strong>in</strong>s <strong>in</strong> advanceof m<strong>in</strong><strong>in</strong>g.Only experience at a given m<strong>in</strong>e can <strong>in</strong>dicate to the operator if clay ve<strong>in</strong>s have the potential <strong>for</strong>gas emission problems. If methane emission problems are encountered, then underground mapp<strong>in</strong>gof clay ve<strong>in</strong>s is needed to predict where they will occur <strong>in</strong> develop<strong>in</strong>g sections. Becauseclay ve<strong>in</strong>s can frequently extend hundreds of feet along a given trend [Chase and Ulery 1987],predict<strong>in</strong>g their occurrence <strong>in</strong> a develop<strong>in</strong>g section will allow the operator to anticipate and/oralleviate the potential gas problem.If the clay ve<strong>in</strong> network <strong>in</strong> a specific m<strong>in</strong>e has a history of gas emission problems, then horizontalmethane dra<strong>in</strong>age boreholes drilled ahead of the face and penetrat<strong>in</strong>g the clay ve<strong>in</strong>are probably the most economical and timely method to remediate the potential problem(Figure 7–7, borehole A). Theoretically, if a clay ve<strong>in</strong> network is well-mapped and a large,isolated “cell” is del<strong>in</strong>eated (Figure 7–8), then the gas could be dra<strong>in</strong>ed through a surface borehole(Figure 7–7, borehole B). Generally, however, this would be a cost-prohibitive course ofaction, necessitated only <strong>in</strong> extreme cases or where drill<strong>in</strong>g costs would be low due to shallowdepths.Figure 7–7.—<strong>Methane</strong> dra<strong>in</strong>age of a clay ve<strong>in</strong> gas barrier.