Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

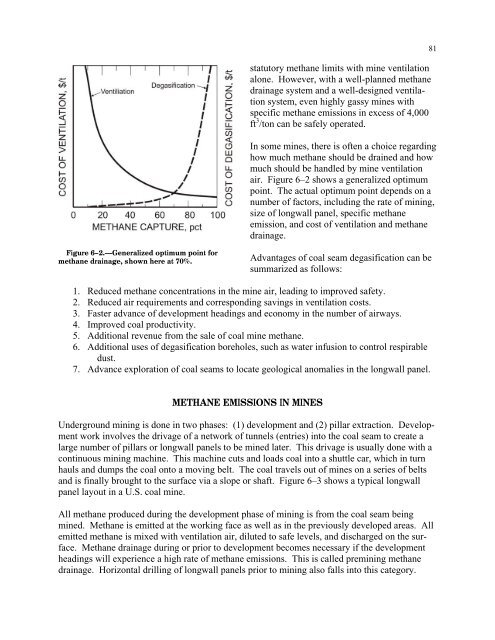

statutory methane limits with m<strong>in</strong>e ventilationalone. However, with a well-planned methanedra<strong>in</strong>age system and a well-designed ventilationsystem, even highly gassy m<strong>in</strong>es withspecific methane emissions <strong>in</strong> excess of 4,000ft 3 /ton can be safely operated.In some m<strong>in</strong>es, there is often a choice regard<strong>in</strong>ghow much methane should be dra<strong>in</strong>ed and howmuch should be handled by m<strong>in</strong>e ventilationair. Figure 6–2 shows a generalized optimumpo<strong>in</strong>t. The actual optimum po<strong>in</strong>t depends on anumber of factors, <strong>in</strong>clud<strong>in</strong>g the rate of m<strong>in</strong><strong>in</strong>g,size of longwall panel, specific methaneemission, and cost of ventilation and methanedra<strong>in</strong>age.81Figure 6–2.—Generalized optimum po<strong>in</strong>t <strong>for</strong>methane dra<strong>in</strong>age, shown here at 70%.Advantages of coal seam degasification can besummarized as follows:1. Reduced methane concentrations <strong>in</strong> the m<strong>in</strong>e air, lead<strong>in</strong>g to improved safety.2. Reduced air requirements and correspond<strong>in</strong>g sav<strong>in</strong>gs <strong>in</strong> ventilation costs.3. Faster advance of development head<strong>in</strong>gs and economy <strong>in</strong> the number of airways.4. Improved coal productivity.5. Additional revenue from the sale of coal m<strong>in</strong>e methane.6. Additional uses of degasification boreholes, such as water <strong>in</strong>fusion to control respirabledust.7. Advance exploration of coal seams to locate geological anomalies <strong>in</strong> the longwall panel.METHANE EMISSIONS IN MINESUnderground m<strong>in</strong><strong>in</strong>g is done <strong>in</strong> two phases: (1) development and (2) pillar extraction. Developmentwork <strong>in</strong>volves the drivage of a network of tunnels (entries) <strong>in</strong>to the coal seam to create alarge number of pillars or longwall panels to be m<strong>in</strong>ed later. This drivage is usually done with acont<strong>in</strong>uous m<strong>in</strong><strong>in</strong>g mach<strong>in</strong>e. This mach<strong>in</strong>e cuts and loads coal <strong>in</strong>to a shuttle car, which <strong>in</strong> turnhauls and dumps the coal onto a mov<strong>in</strong>g belt. The coal travels out of m<strong>in</strong>es on a series of beltsand is f<strong>in</strong>ally brought to the surface via a slope or shaft. Figure 6–3 shows a typical longwallpanel layout <strong>in</strong> a U.S. coal m<strong>in</strong>e.All methane produced dur<strong>in</strong>g the development phase of m<strong>in</strong><strong>in</strong>g is from the coal seam be<strong>in</strong>gm<strong>in</strong>ed. <strong>Methane</strong> is emitted at the work<strong>in</strong>g face as well as <strong>in</strong> the previously developed areas. Allemitted methane is mixed with ventilation air, diluted to safe levels, and discharged on the surface.<strong>Methane</strong> dra<strong>in</strong>age dur<strong>in</strong>g or prior to development becomes necessary if the developmenthead<strong>in</strong>gs will experience a high rate of methane emissions. This is called prem<strong>in</strong><strong>in</strong>g methanedra<strong>in</strong>age. Horizontal drill<strong>in</strong>g of longwall panels prior to m<strong>in</strong><strong>in</strong>g also falls <strong>in</strong>to this category.